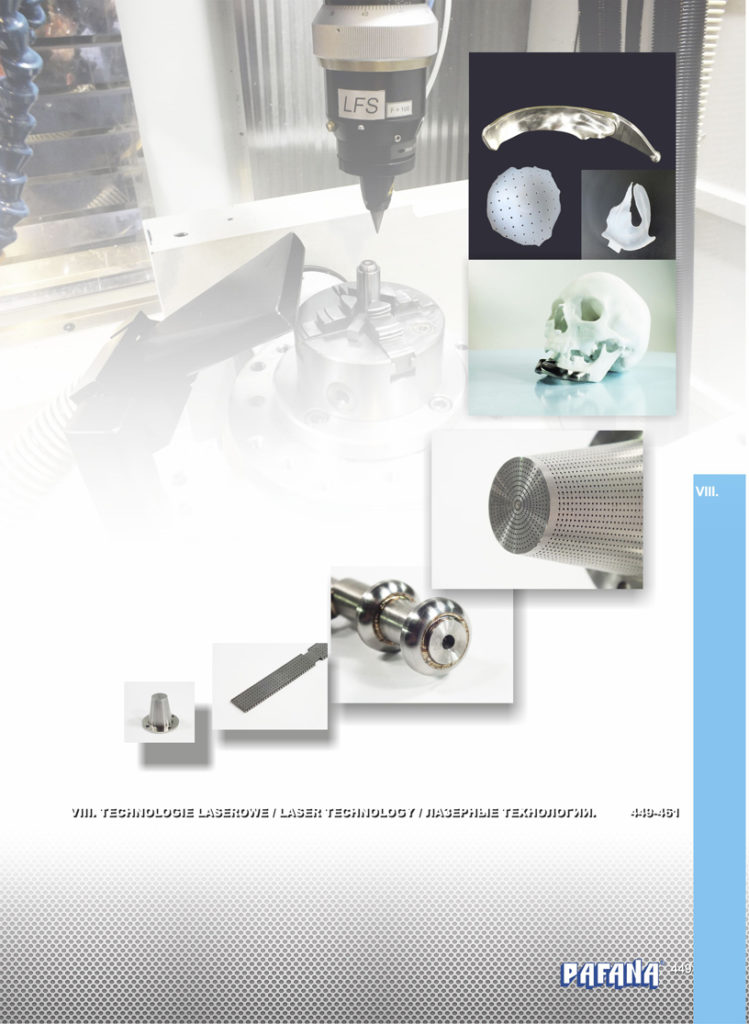

Laser Technology

LASER TECHNOLOGY OF PAFANA.

We would like to encourage you to take advantage of our offer regarding the use of efficient

2D and 3D laser treatment. We have an opportunity to use a fibre laser with the output of

up to 3kW and a pulsed laser with the output of up to 12 kW.

The advantages of the technology are:

– faster and cheaper machining,

– precise technology of drilling, cutting and welding on a single machine,

– contact-free treatment,

– possibility of cutting of very thin materials,

– cutting of even very small and complicated shapes in 3, 4 and 5-axes,

– work in very hard materials.

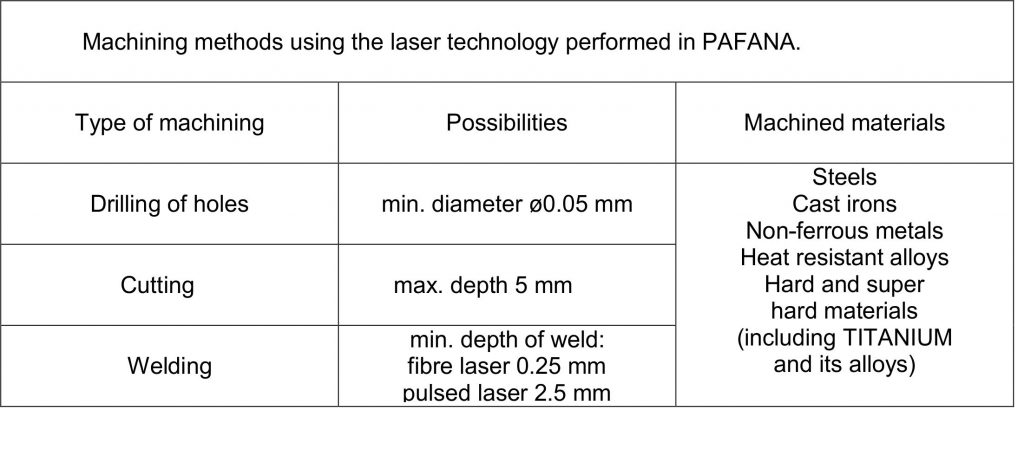

Machining methods using the laser technology performed in PAFANA.

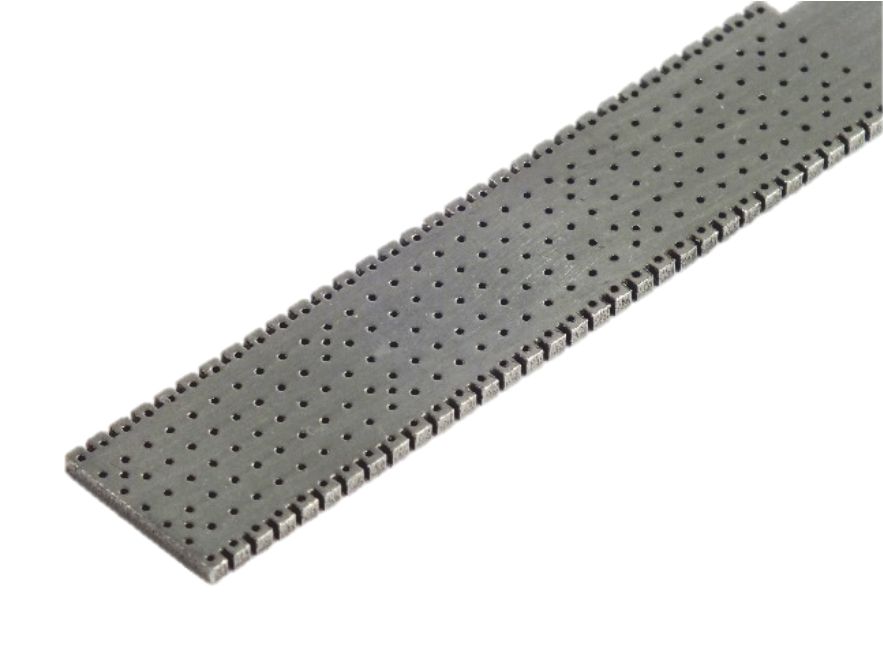

- Type of machining – Drilling of holes. Possibilities – min. diameter ø0.05 mm. Machined materials – steels, cast irons, non-ferrous metals, heat resistant alloys, hard and super hard materials (including TITANIUM and its alloys).

- Type of machining – Cutting – Possibilities – max. depth 5 mm. Machined materials – steels, cast irons, non-ferrous metals, heat resistant alloys, hard and super hard materials (including TITANIUM and its alloys).

- Type of machining – Welding – Possibilities -min. depth of weld: fibre laser 0.25 mm, pulsed laser 2.5 mm. Machined materials – steels, cast irons, non-ferrous metals, heat resistant alloys, hard and super hard materials (including TITANIUM and its alloys).

Our experts will help you select the proper laser technology which makes it possible to

increase efficiency and quality of the product while reducing the cost of its manufacture

at the same time. The offer also includes the support in identifying the products whose

current manufacture can be changed into the laser technology.

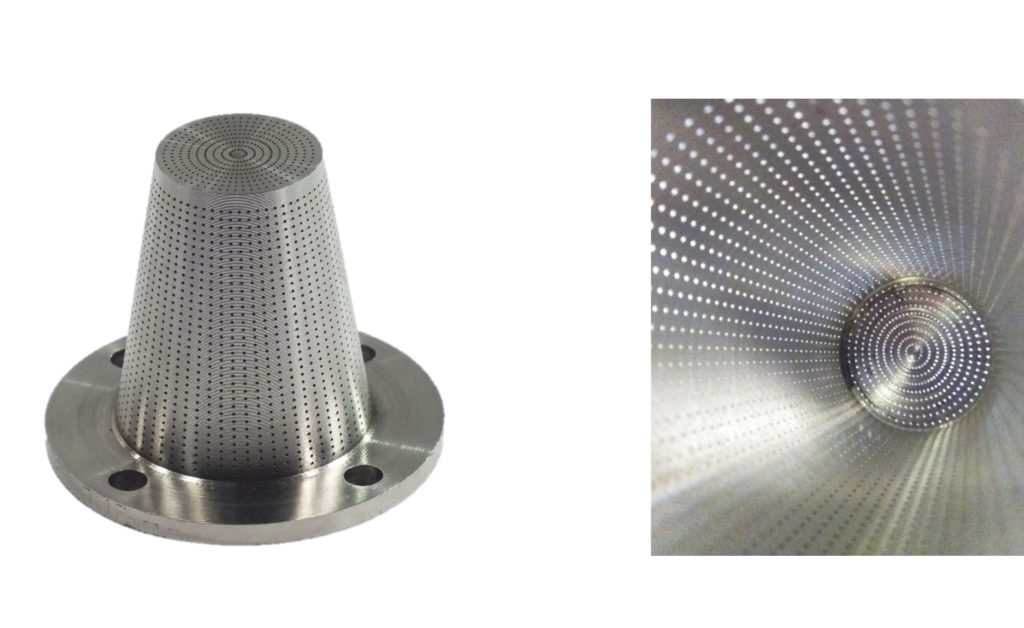

Examples of details made by the laser technology:

Drilling of holes in the cone type filter – 2301 holes ø0,3÷0,03

Cutting of shape and holes in the electric panel – 321 holes ø0,55±0,05

Drilling of holes in the filter – 163 holes ø0,45±0,05

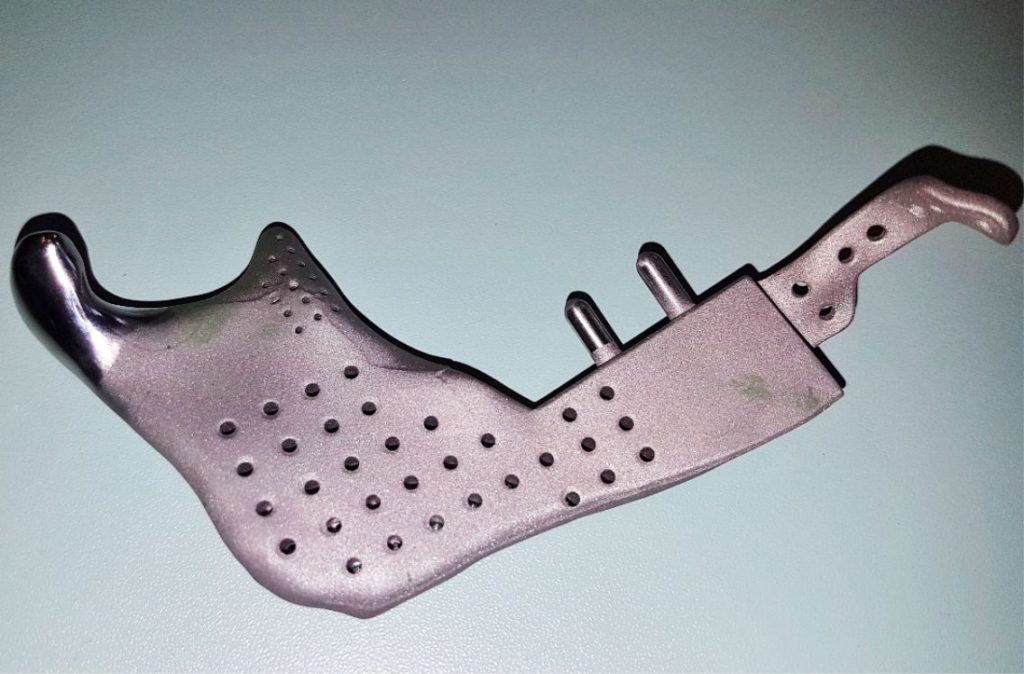

Precise 4-axis welding of the medical implant.

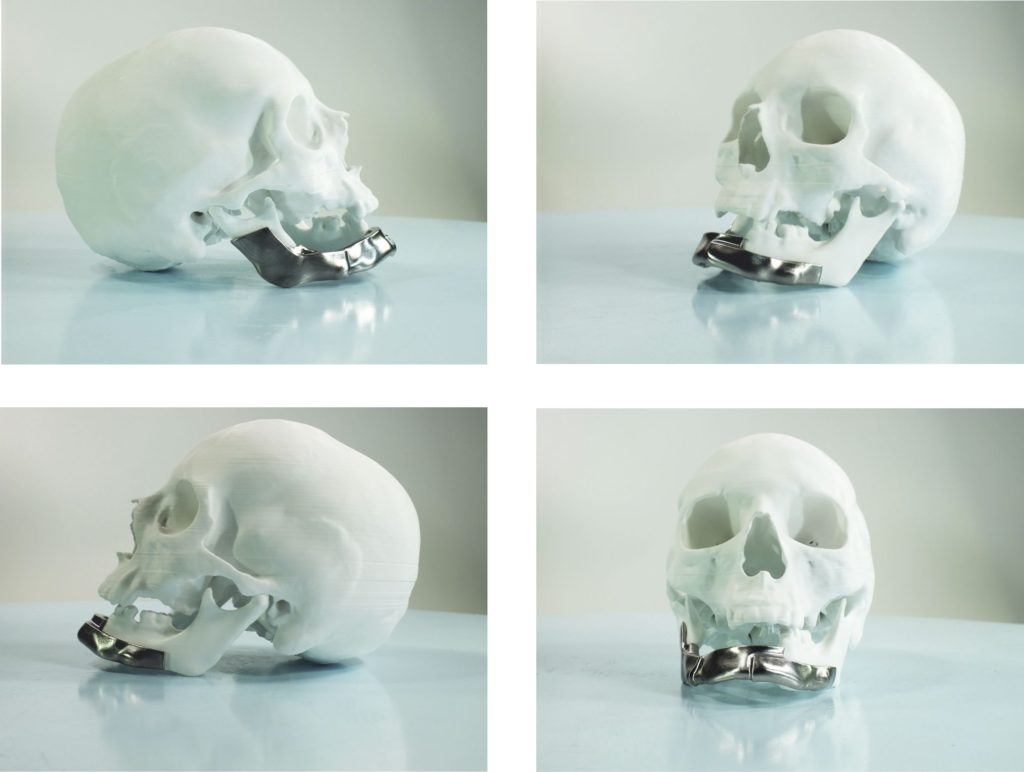

INDIVIDUAL MEDICAL IMPLANT.

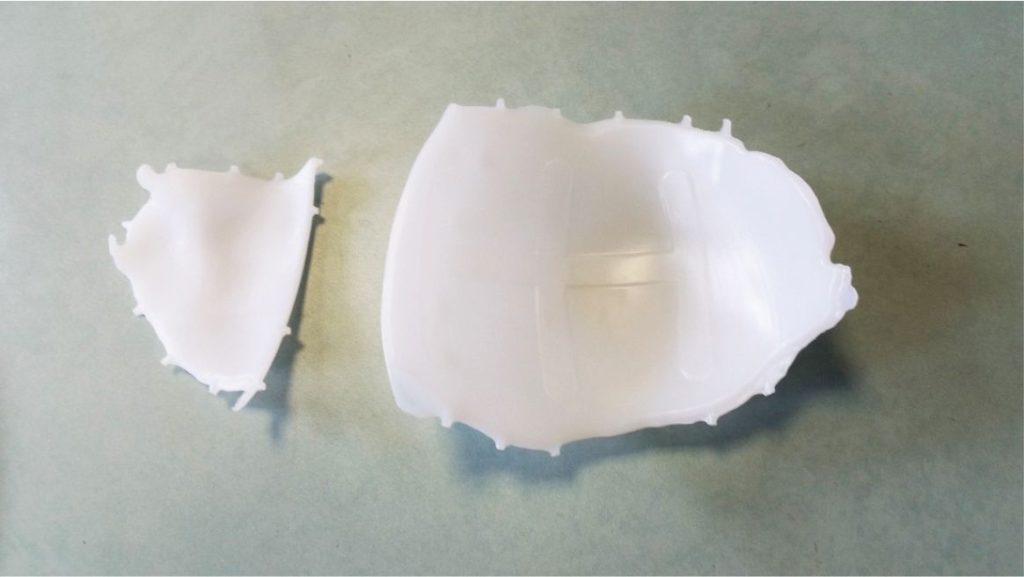

The engineers from the Product Development Department of the Pabianice Tool Factory

„PAFANA” S.A. have developed a unique technology of the efficient manufacture of individual

facio-cranial medical implants. The individual implants are designed for a specific patient who

was injured in an accident or whose facio-cranial bones were amputated as a result of

neoplastic lesions. The reconstructed organ is designed by specialists using professional

graphics software on the basis of the computer tomography’s records of the patient’s healthy

and damaged bones. The verified model of the implant is 3D printed and accepted by a surgeon.

A team of PAFANA technologists and programmers makes a ready implant of medical materials:

Chirulen medical polyethylene or Ti6Al4V-5ELI medical titanium alloy.

Now the manufacturing technology of three types of implants is mastered:

Implant of cranial plate „Krianoplastyka” – made of Chirulen plastic.

Implant of orbital cavity „Orbit” – made of Chirulen plastic.

Implant of mandible „Mandible” – made of Ti6Al4V 5ELI medical titanium alloy.

Implant of mandible placed in the 3D skull model.