PAFANA Technical BLOG

I. TOOLHOLDERS. PAFANA TOOLHOLDERS FOR THREADING.

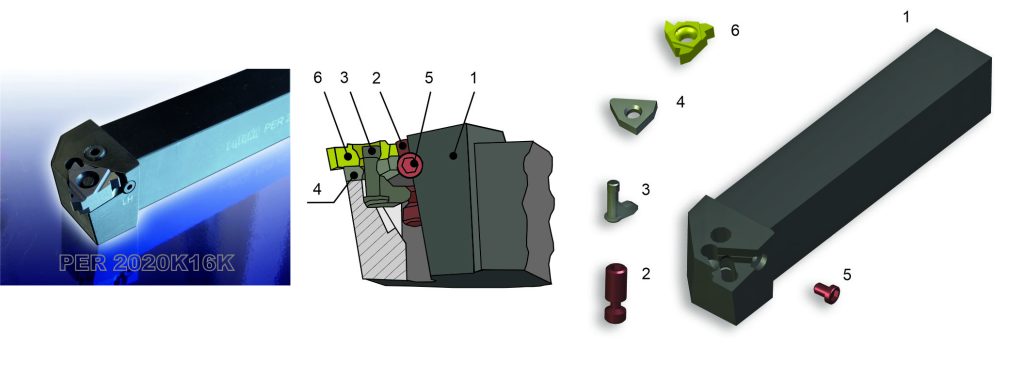

1 – holder. 2 – screw. 3 – lever.

4 – shim. 5 – shim screw.

6 – cutting insert.

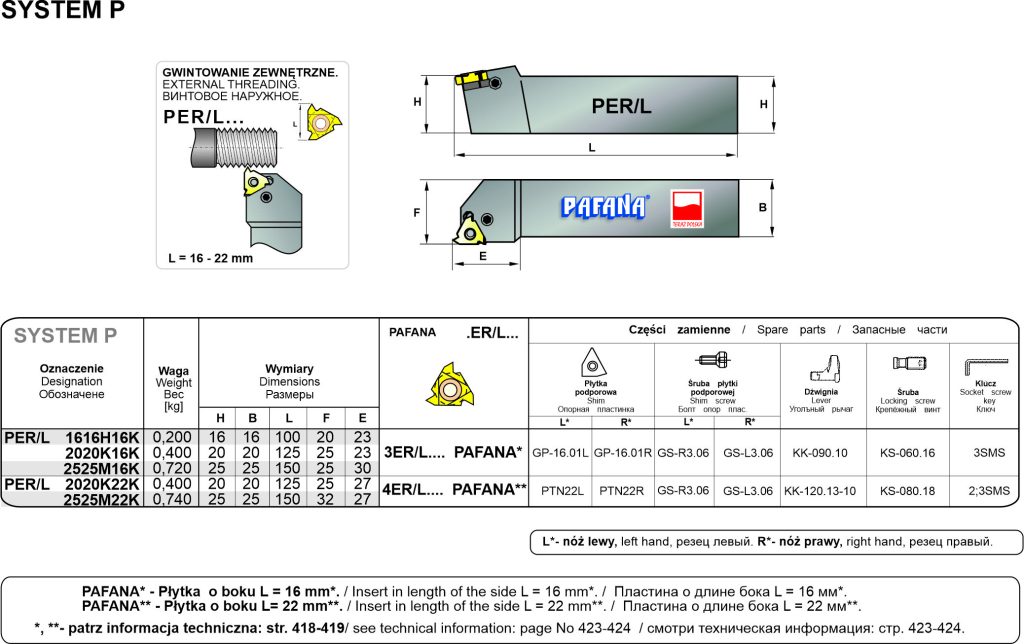

PFN PAFANA S.A. BEGAN ITS PATH OF DEVELOPMENT OF TOOLHOLDERS FOR THREADING WITH TOOLHOLDERS TYPE PER/L.

TOOLHOLDERS FOR THREADING.

CLAMPING SYSTEM FOR INSERTS – „P-K”. „P-K” SYSTEM – NEGATIVE GEOMETRY OF TOOLHOLDERS.

Inserts with holes designed for external threading with thread pitch up to 4 mm

(of various producers) can be installed on the PER/L… ..K toolholders. Thanks to their appropriate seat shape and lever fixing system the triangular cutting inserts of the 16 mm side length (IC=9,525 mm) and 22 mm are positioned and fixed properly independently of their thickness and the hole diameter. The cutting tool is equipped with a shim that provides: – protection (in case of insert’s damage), – correction (of tool geometry).

ASSORTMENT:

PER/L1616H16K

PER1616H16K

PEL1616H16K

PER/L2020K16K

PER2020K16K

PEL2020K16K

PER/L2525M16K

PER2525M16K

PEL2525M16K

PAFANA INSERTS:

3ER/L…. PAFANA

PER/L2020K22K

PER/L2525M22K

PAFANA INSERTS:

4ER/L…. PAFANA

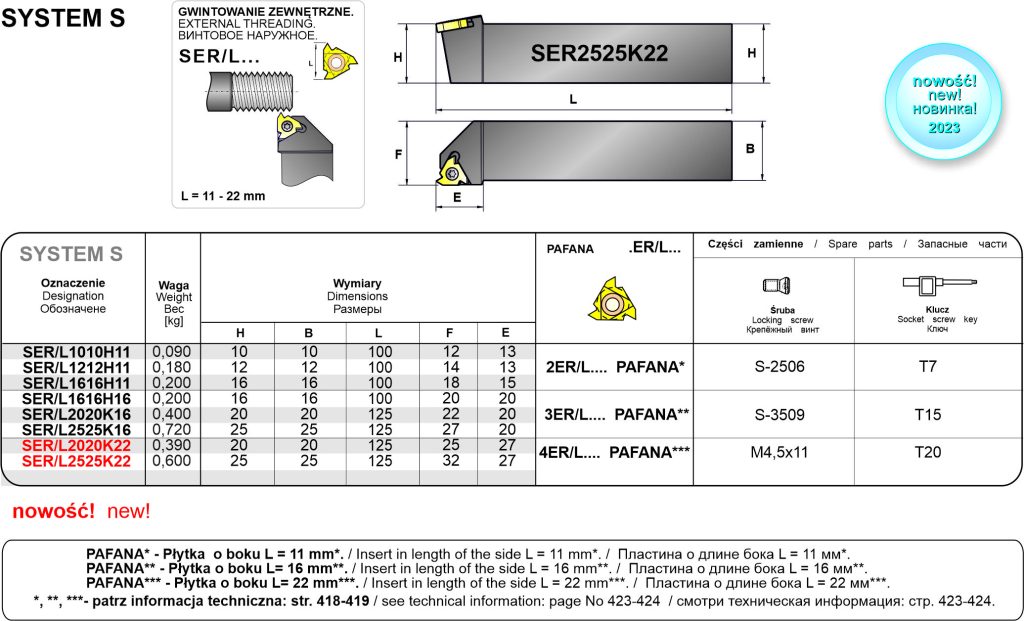

THEN THERE WERE TOOLHOLDERS IN THE “S” CLAMPING SYSTEM FOR INSERTS, TYPE SER/L, FOR INSERTS SIDE LENGTH 11 MM, 16 MM, 22 MM. THE LAST ONES FOR SIDE LENGTH 22 MM INSERTS ARE NEW FOR 2023.

ASSORTMENT:

SER/L1010H11

SER1010H11

SEL1010H11

SER/L1212H11

SER1212H11

SEL1212H11

SER/L1616H11

SER1616H11

SEL1616H11

PAFANA INSERTS:

2ER/L…. PAFANA

SER/L1616H16

SER1616H16

SEL1616H16

SER/L2020K16

SER2020K16

SEL2020K16

SER/L2525K16

SER2525K16

SE 2525K16

PAFANA INSERTS:

3ER/L…. PAFANA

SER/L2020K22

SER2020K22

SEL2020K22

SER/L2525K22

SER2525K22

SEL2525K22

PAFANA INSERTS:

4ER/L…. PAFANA

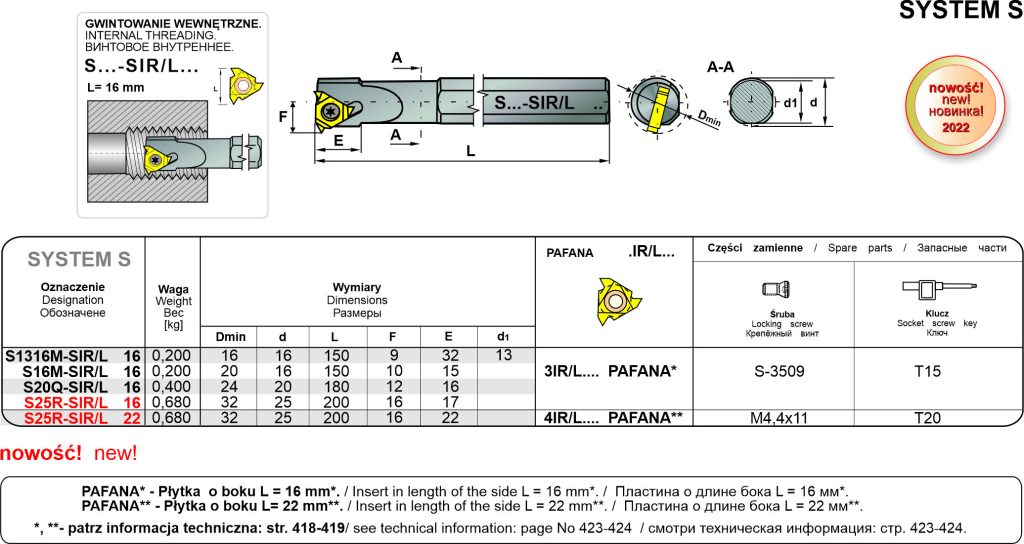

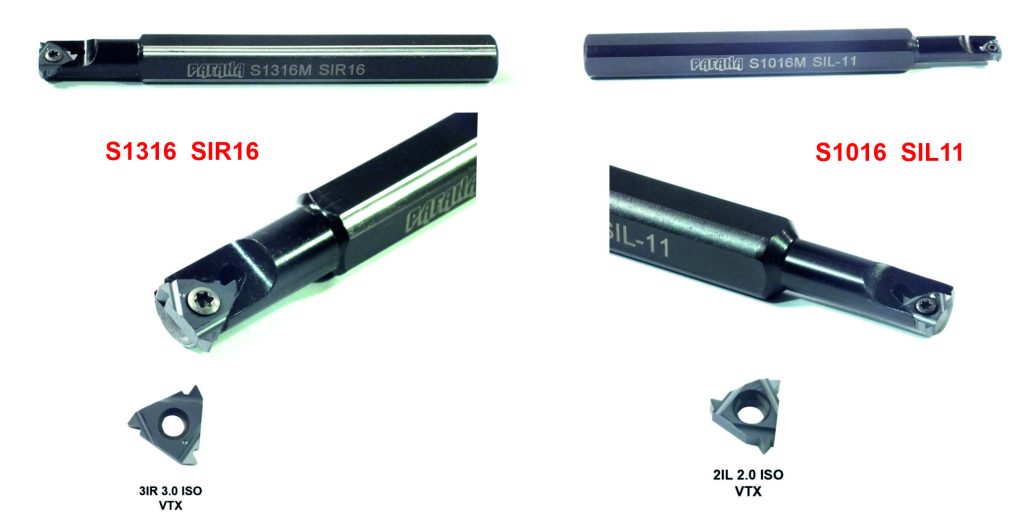

SOON THEY ALSO APPEARED BORING TOOLS WITH FULLY GROUND SHANKS – SYSTEM S.

WITH A WIDE RANGE OF APPLICATIONS FOR INSERTS WITH SIDES FROM 11 MM TO 22 MM.

ASSORTMENT:

S1016M-SIR/L11

S1016M-SIR11

S1016M-SIL11

S10K-SIR/L11

S10K-SIR11

S10K-SIL11

S12M-SIR/L11

S12M-SIR11

S12M-SIL11

PAFANA INSERTS:

2IR/L…. PAFANA

ASSORTMENT:

S1316M-SIR/L16

S1316M-SIR16

S1316M-SIL16

S16M-SIR/L16

S16M-SIR16

S16M-SIL16

S20Q-SIR/L16

S20Q-SIR16

S20Q-SIL16

S25R-SIR/L16

S25R-SIR16

S25R-SIL16

PAFANA INSERTS:

3IR/L…. PAFANA

S25R-SIR/L22

S25R-SIR22

S25R-SIL22

PŁYTKI PAFANA:

PAFANA INSERTS:

4IR/L…. PAFANA

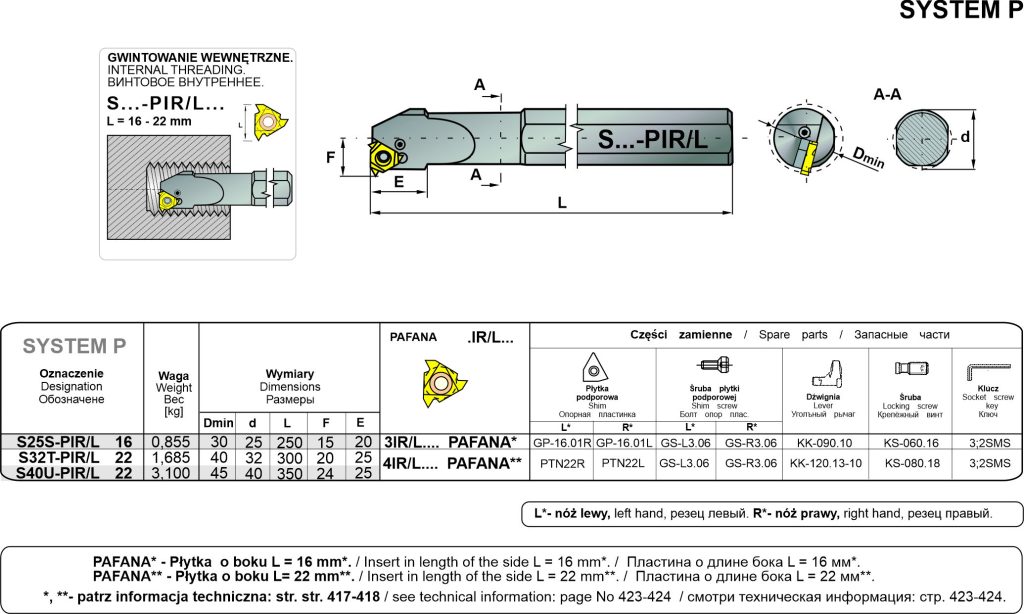

AS WELL AS IN THE TYPE S…-PIR/L BORING TOOLS IN SYSTEM P WITH VERY STABLE MACHINING CONDITIONS WITH LARGE 16 MM AND 22 MM INSERTS.

ASSORTMENT:

S25S-PIR/L16

S25S-PIR16

S25S-PIL16

PAFANA INSERTS:

3IR/L…. PAFANA

S32T-PIR/L22

S32T-PIR22

S32T-PIL22

S40U-PIR/L22

S40U-PIR22

S40U-PIL22

PAFANA INSERTS:

4IR/L…. PAFANA

see the PAFANA on-line catalog: http://pafana.elkat.eu/#0

see the assortment of the PAFANA catalog edition 07/2020: https://pafana.pl/en/products/toolholders-clamping-systems-for-inserts-system-s-boring-bars-with-sintered-carbide-shank-tool-holders-vdi-pta-20-28-boring-cartridges-toolholders-for-automatic-lathes-system-p-p-k-d-m-c-system-c-to/

see PAFANA news: https://pafana.pl/en/products/new/

Przygotował: Zdzisław Pawlak po. Kierownika Działu Marketingu i Eksportu PFN PAFANA S.A. 03.04.2023.

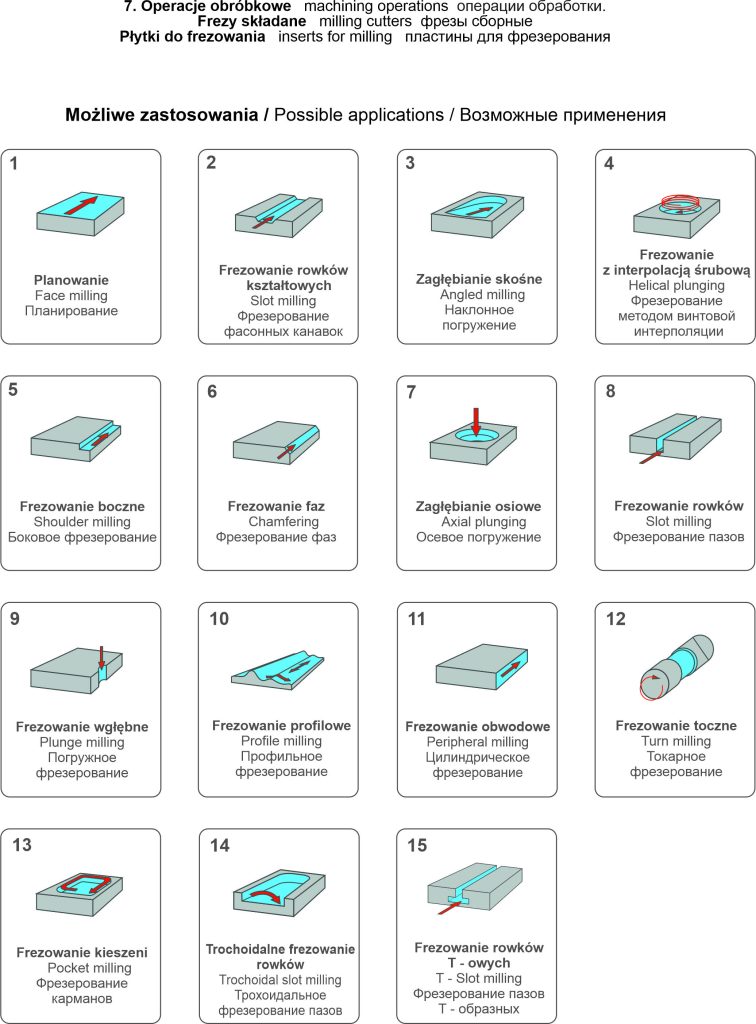

MILLING CUTTERS PFN PAFANA S.A. FOR MILLING INSERTS COVERING A VERY WIDE SPECTRUM OF MACHINING OPERATIONS:

I.

1 – FACE MILLING, 3 – ANGLED MILLING, 4 – HELICAL PLUNGING, 5 – SHOULDER MILLING, 8 – SLOT MILLING, 11 – PERIPHERAL MILLING, 14. TROCHOIDAL SLOT MILLING.

II.

1 – FACE MILLING, 2 – SLOT MILLING, 3 – ANGLED MILLING, 4 – HELICAL PLUNGING,

9 – PLUNGE MILLING, 10 – PROFILE MILLING, 12 – TURN MILLING, 13 – POCKET MILLING.

III.

1 – FACE MILLING, 3 – ANGLED MILLING, 4 – HELICAL PLUNGING, 5 – SHOULDER MILLING, 8 – SLOT MILLING, 14. TROCHOIDAL SLOT MILLING.

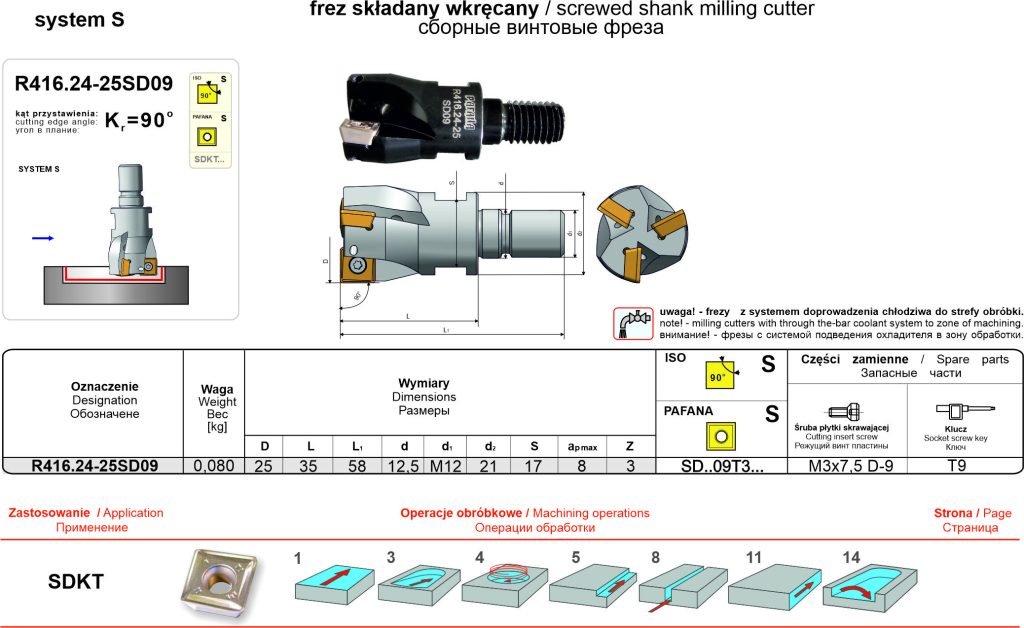

WE PRESENT ANOTHER VERY HELPFUL GROUP OF MILLING CUTTERS: R416, R516, R616, R518, R454, R554, R654. R61L.21.

I.

1.SCREWED SHANK MILLING CUTTER – R416.24-25SD09, SD..09T3…

MACHINING OPERATIONS: 1 – FACE MILLING, 3 – ANGLED MILLING, 4 – HELICAL PLUNGING, 5 – SHOULDER MILLING, 8 – SLOT MILLING, 11 – PERIPHERAL MILLING, 14. TROCHOIDAL SLOT MILLING.

ASSORTMENT:

R416.24-25SD09

PAFANA INSERTS SD..09T3…:

SDKT09T3..

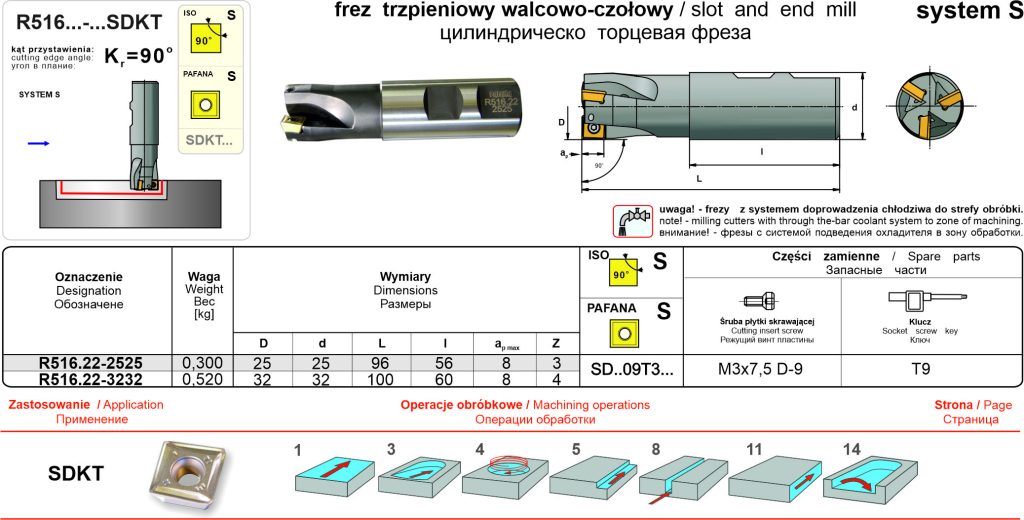

2. SLOT AND END MILL – R516…-…SDKT, SD..09T3…

MACHINING OPERATIONS: 1 – FACE MILLING, 3 – ANGLED MILLING, 4 – HELICAL PLUNGING, 5 – SHOULDER MILLING, 8 – SLOT MILLING, 11 – PERIPHERAL MILLING, 14. TROCHOIDAL SLOT MILLING.

ASSORTMENT:

R516.22-2525

R516.22-3232

PAFANA INSERTS SD..09T3…:

SDKT09T3..

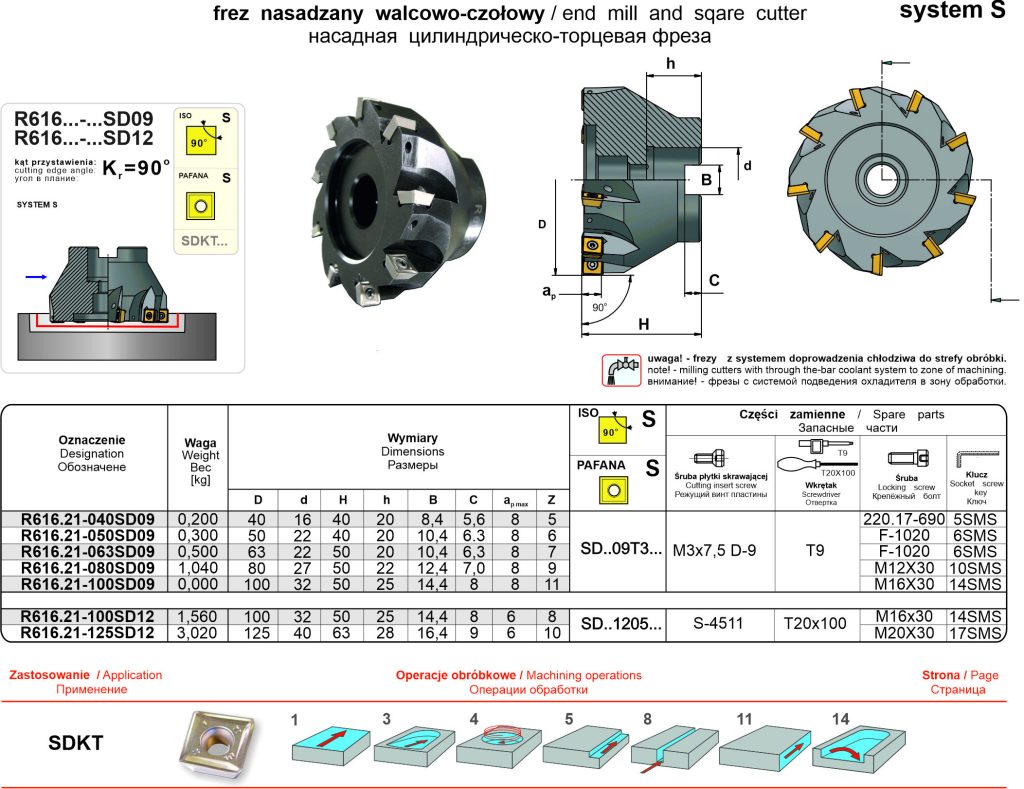

3. END MILL AND SQARE CUTTER – R616…-…SD09, SD..09T3…

R616…-…SD12, SD..1205…

MACHINING OPERATIONS: 1 – FACE MILLING, 3 – ANGLED MILLING, 4 – HELICAL PLUNGING, 5 – SHOULDER MILLING, 8 – SLOT MILLING, 11 – PERIPHERAL MILLING, 14. TROCHOIDAL SLOT MILLING.

ASSORTMENT:

R616.21-040SD09

R616.21-050SD09

R616.21-063SD09

R616.21-080SD09

R616.21-100SD09

PAFANA INSERTS SD..09T3…:

SDKT 09T3..

ASSORTMENT:

R616.21-100SD12

R616.21-125SD12

PAFANA INSERTS SD..1205…:

SDKT 1205…

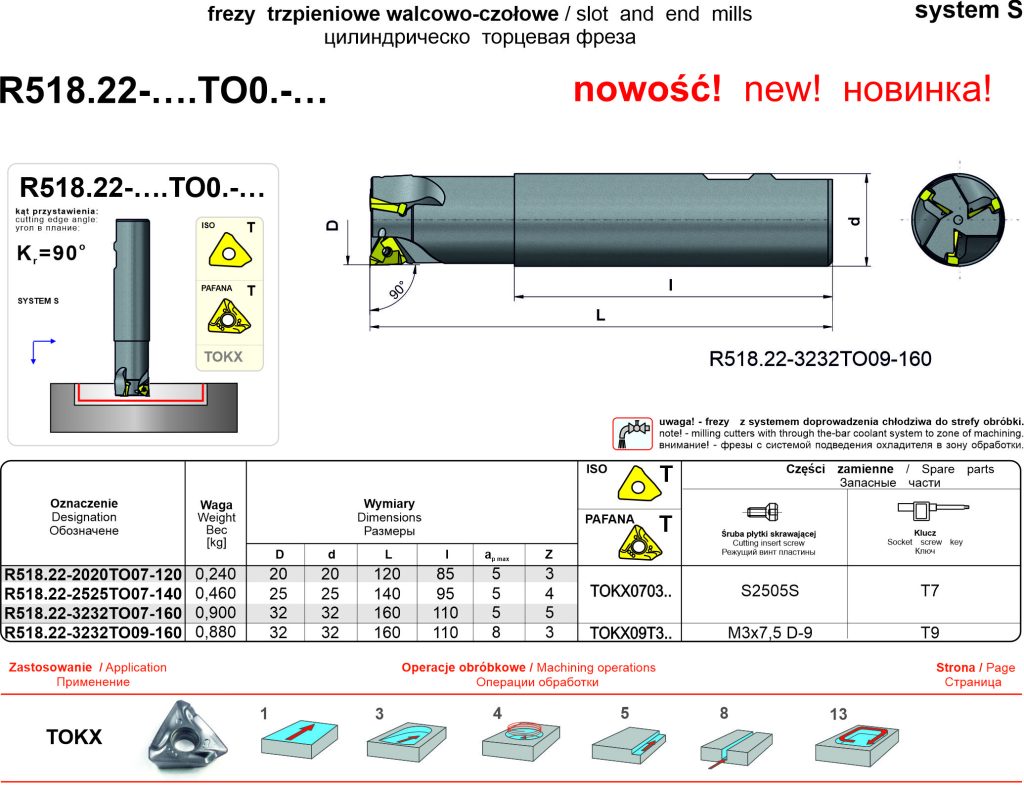

4. SLOT AND END MILL – R518.22-….TO0.-…, TOKX0703..,

TOKX09T3..

MACHINING OPERATIONS: 1 – FACE MILLING, 3 – ANGLED MILLING, 4 – HELICAL PLUNGING, 5 – SHOULDER MILLING, 8 – SLOT MILLING, 11 – PERIPHERAL MILLING, 14. TROCHOIDAL SLOT MILLING.

ASSORTMENT:

R518.22-2020TO07-120

R518.22-2525TO07-140

R518.22-3232TO07-160

PAFANA INSERTS TOKX0703..:

TOKX 0703..

ASSORTMENT:

R518.22-3232TO09-160

PAFANA INSERTS TOKX09T3..:

TOKX 09T3..

II.

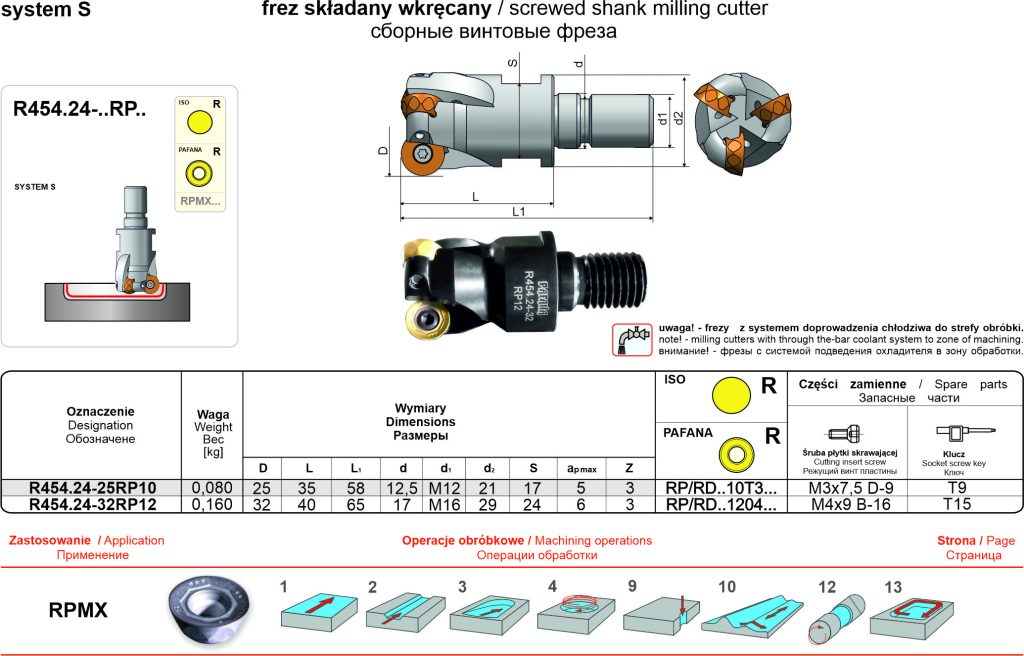

5. SCREWED SHANK MILLING CUTTER – R454.24-..RP.., RP/RD..10T3…, RP/RD..1204…

MACHINING OPERATIONS: 1 – FACE MILLING, 2 – SLOT MILLING, 3 – ANGLED MILLING,

4 – HELICAL PLUNGING, 9 – PLUNGE MILLING, 10 – PROFILE MILLING,

12 – TURN MILLING, 13 – POCKET MILLING.

ASSORTMENT:

R454.24-25RP10

PAFANA INSERTS RP/RD..10T3…:

RPLT 10T3…

RDLT10T3…

ASSORTMENT:

R454.24-32RP12

PAFANA INSERTS RP/RD..1204…:

RPLT 1204…

RDLT 1204…

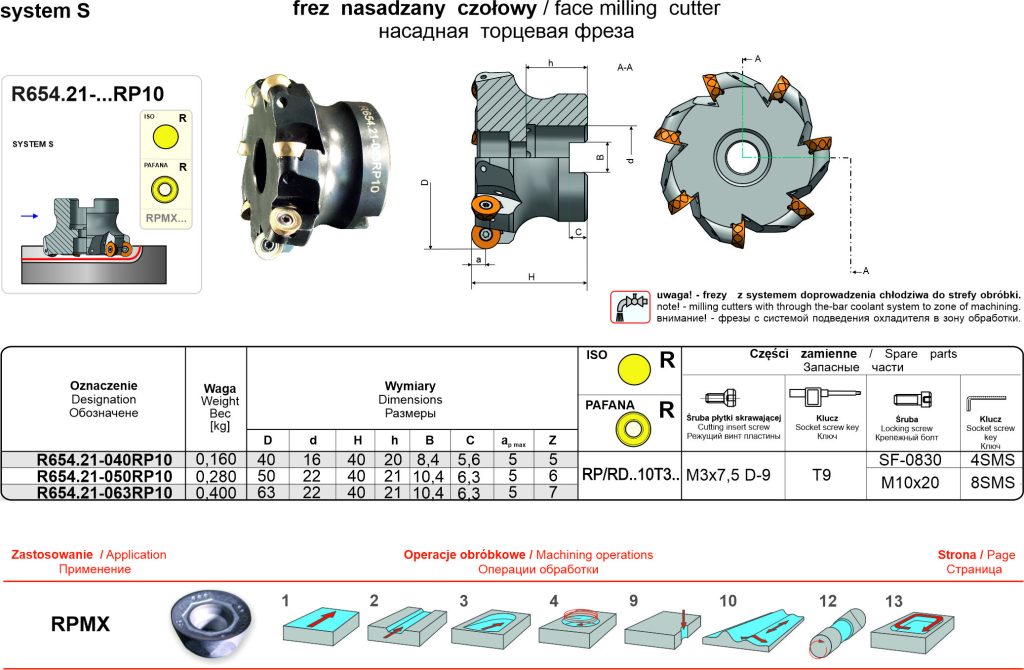

6. FACE MILLING CUTTER – R654.21-…RP10, RP/RD..10T3..

MACHINING OPERATIONS: 1 – FACE MILLING, 2 – SLOT MILLING, 3 – ANGLED MILLING,

4 – HELICAL PLUNGING, 9 – PLUNGE MILLING, 10 – PROFILE MILLING,

12 –TURN MILLING, 13 – POCKET MILLING.

ASSORTMENT:

R654.21-040RP10

R654.21-050RP10

R654.21-063RP10

PAFANA INSERTS RP/RD..10T3…:

RPLT 10T3…

RDLT 10T3…

III.

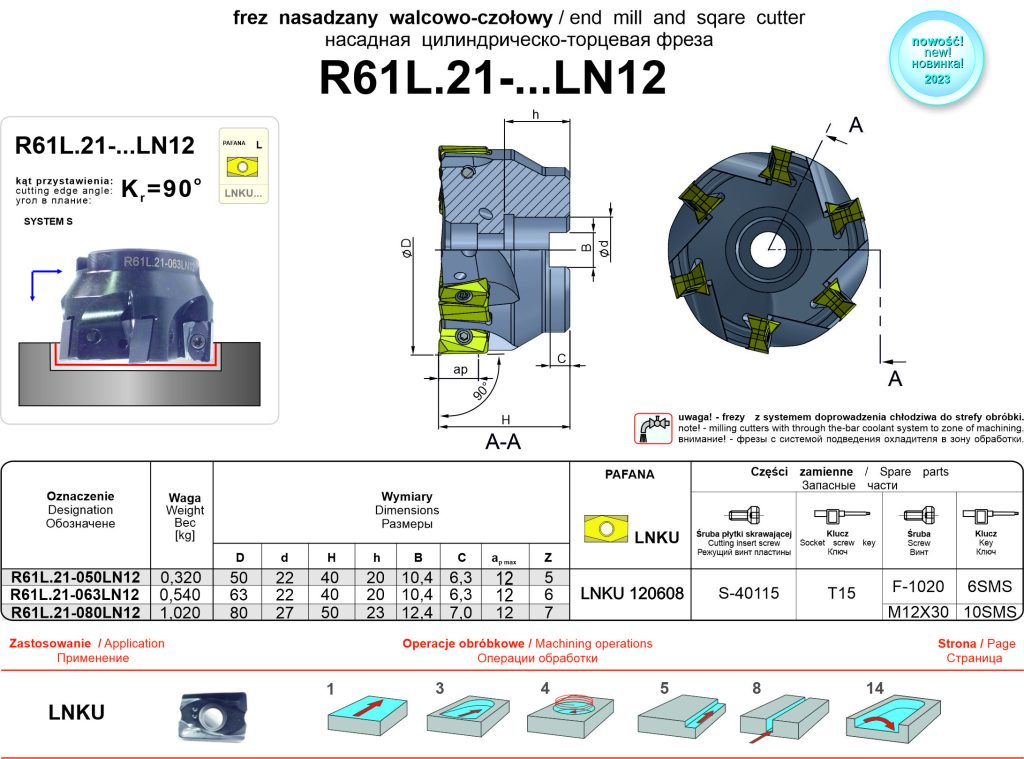

7. END MILL AND SQARE CUTTER R61.L21-…LN12, LNKU120608

MACHINING OPERATIONS: 1 – FACE MILLING, 3 – ANGLED MILLING, 4 – HELICAL PLUNGING, 5 – SHOULDER MILLING, 8 – SLOT MILLING, 14. TROCHOIDAL SLOT MILLING.

ASSORTMENT:

R61L.21-050LN12

R61L.21-063LN12

R61L.21-080LN12

PAFANA INSERTS LNKU 120608 ER-… …..:

LNKU 120608 ER S7M BP30R (P), FP35T (P),

LNKU 120608 ER S6M FM40S (M),

LNKU 120608 ER S8M BK15S (K).

see the PAFANA on-line catalog: http://pafana.elkat.eu/#0

see the assortment of the PAFANA catalog edition 07/2020: https://pafana.pl/en/products/milling-cutters-of-pafana-possible-applications-face-milling-slot-milling-angled-milling-helical-plunging-shoulder-milling-chamfering-axial-plunging-slot-milling-plunge-milling-profile-milling-periphe/

see PAFANA news: https://pafana.pl/en/products/new/

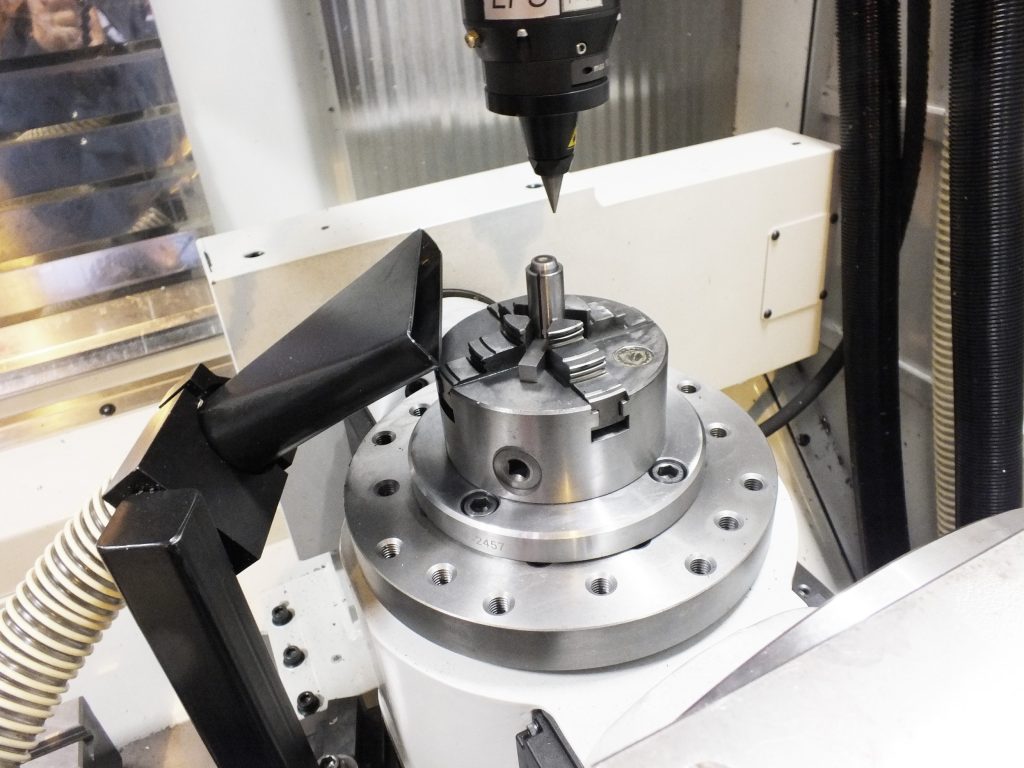

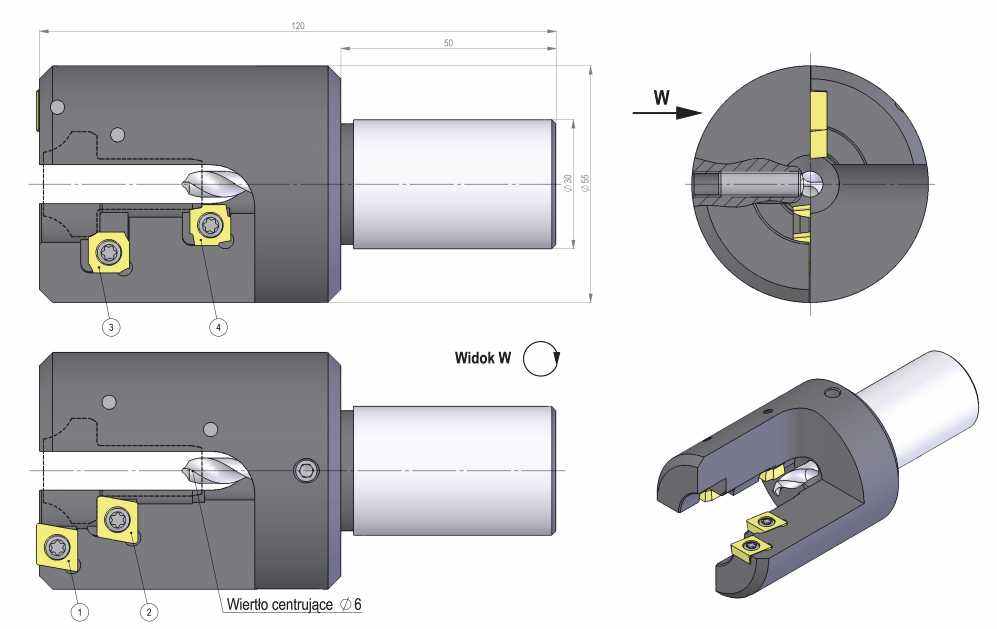

BORING MODULAR SYSTEM “MULTI PAFANA”.

WE PRESENT ANOTHER INTERESTING ELEMENT OF THE “MULTI PAFANA” SYSTEM.

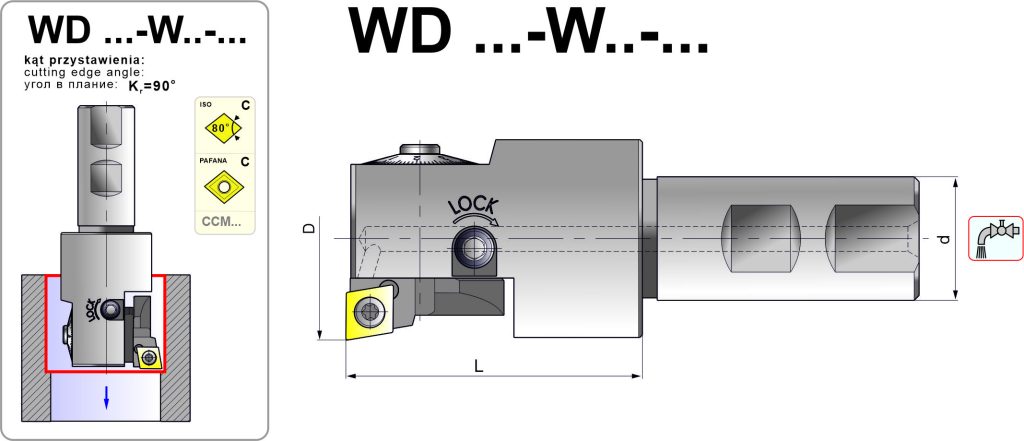

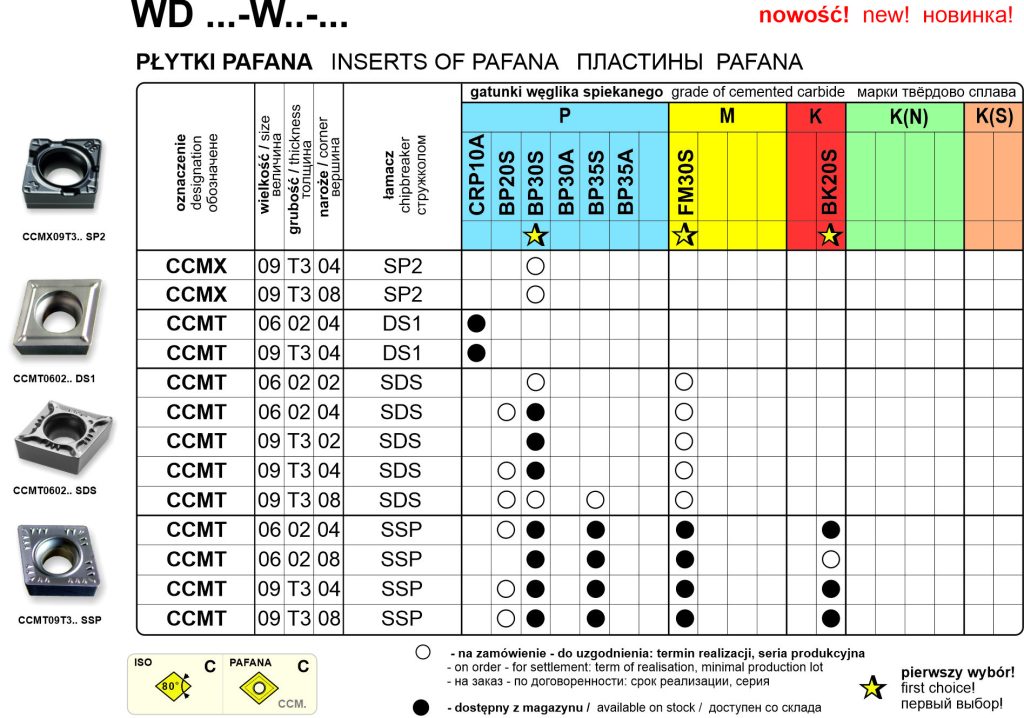

BORING BARS WITH CYLINDRICAL SHANK (WELDON) WD …-W..-… PAFANA.

BORING RANGE FROM 34 TO 80 MM DIAMETER AND UP TO 150 MM DEPTH.

TECHNICAL INFORMATION:

WD… group boring tools of PAFANA with a cylindrical shank (so-called WELDON) combine the precision of PAFANA NWGD-type boring heads with the possibility of clamping them in standard milling tool holders on most machine tools.

WD… precise boring bars are designed for precise machining of through and blind holes (cutting angle 90°) with diameters from 34 to 80 mm and a depth of up to 150 mm.

They provide the ability to adjust the machined diameter to an accuracy of 0.01 mm.

The supply of cutting fluid through the tool shank ensures optimum working conditions for the cutting insert and facilitates chip evacuation.

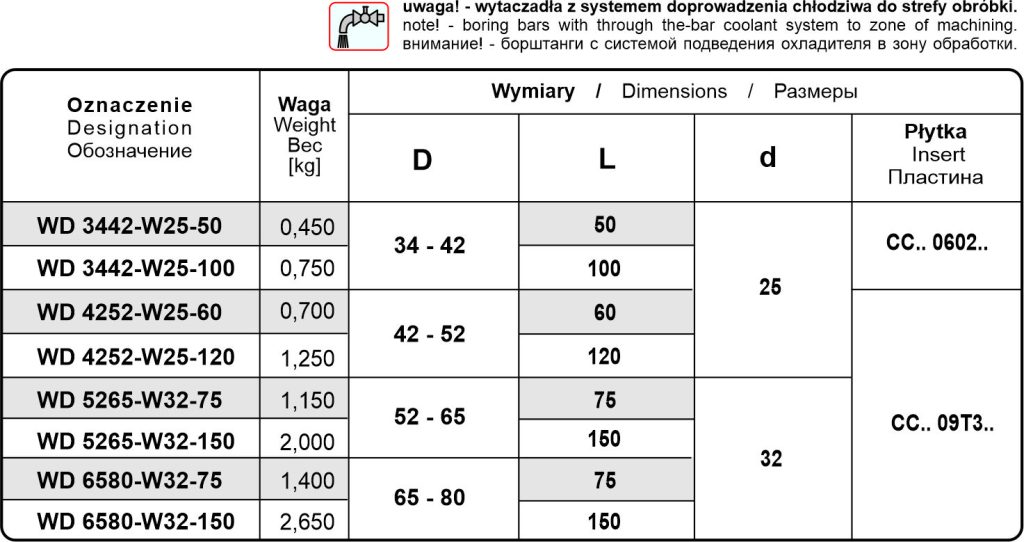

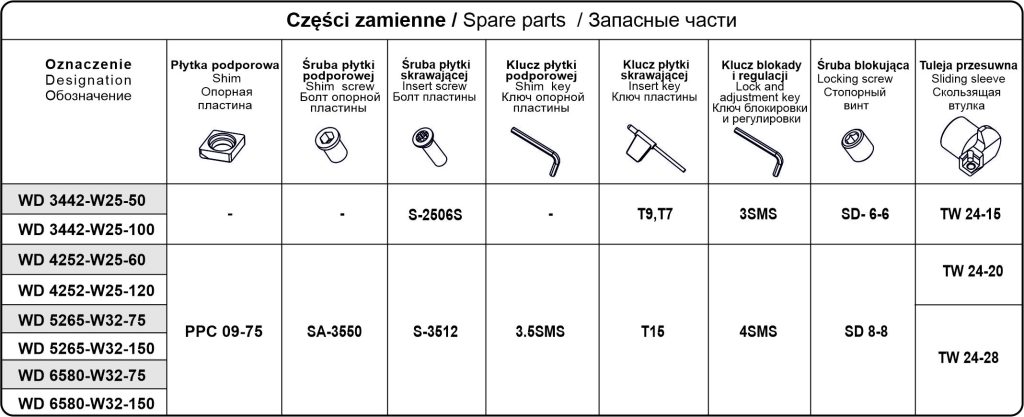

ASSORTMENT:

WD 3442-W25-50

WD 3442-W25-100

PAFANA INSERTS CC.. 0602..:

CCMT060204 DS1 CRP10A (P),

CCMT060202 SDS BP30S (P),

CCMT060204 SDS BP30S (P),

CCMT060204 SSP BP30S (P), BP35S (P), FM30S (M), BK20S (K),

CCMT060208 SSP BP30S (P), BP35S (P), FM30S (M), BK20S (K),

ASSORTMENT:

WD 4252-W25-60

WD 4252-W25-120

WD 5265-W32-75

WD 5265-W32-150

WD 6580-W32-75

WD 6580-W32-150

PAFANA INSERTS CC.. 09T3..:

CCMX09T304 SP2 BP30S (P),

CCMX09T308 SP2 BP30S (P),

CCMT09T304 DS1 CRP10A (P),

CCMT09T302 SDS BP30S (P), FM30S (M),

CCMT09T304 SDS BP30S (P), FM30S (M),

CCMT09T308 SDS BP30S( P), FM30S (M),

CCMT09T304 SSP BP20S (P), BP30S (P), BP35S (P), FM30S (M), BK20S (K),

CCMT09T308 SSP BP20S (P), BP30S (P), BP35S (P), FM30S (M), BK20S (K).

see the PAFANA on-line catalog: http://pafana.elkat.eu/#0

see the assortment of the PAFANA catalog edition 07/2020: https://pafana.pl/en/products/boring-bars-of-pafana-boring-modular-system-multi-pafana/

see PAFANA news: https://pafana.pl/en/products/new/

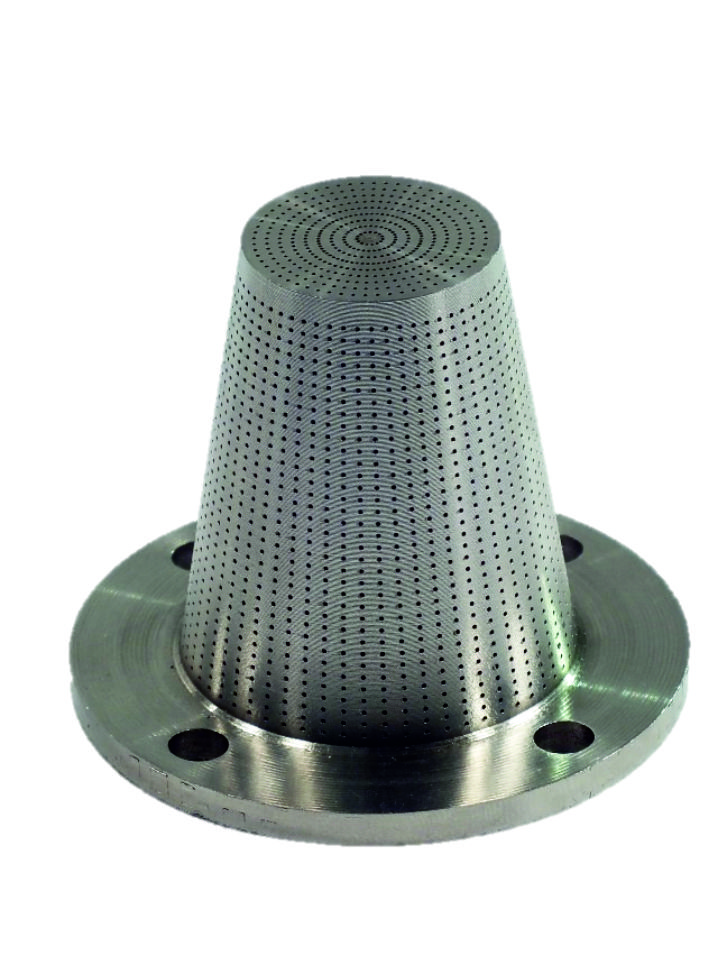

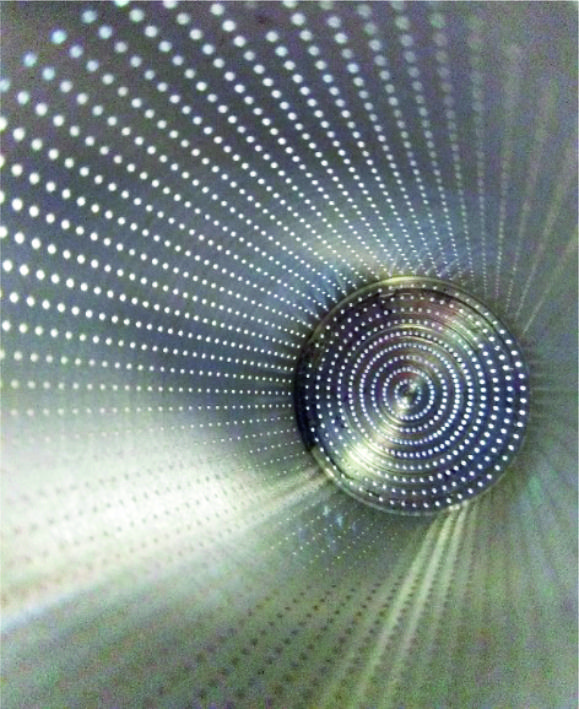

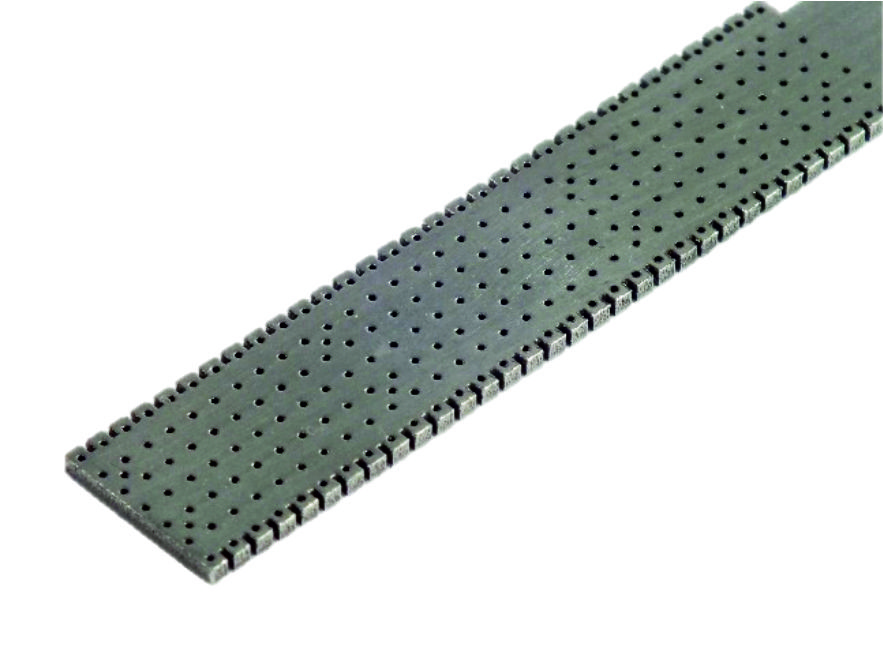

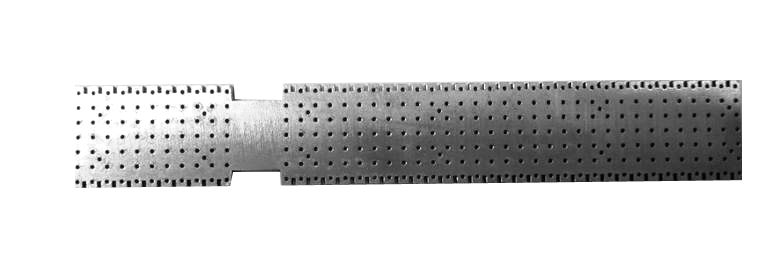

PAFANA LASER TECHNOLOGIES.

Laser technology: medical implants, 2D, 3D laser processing.

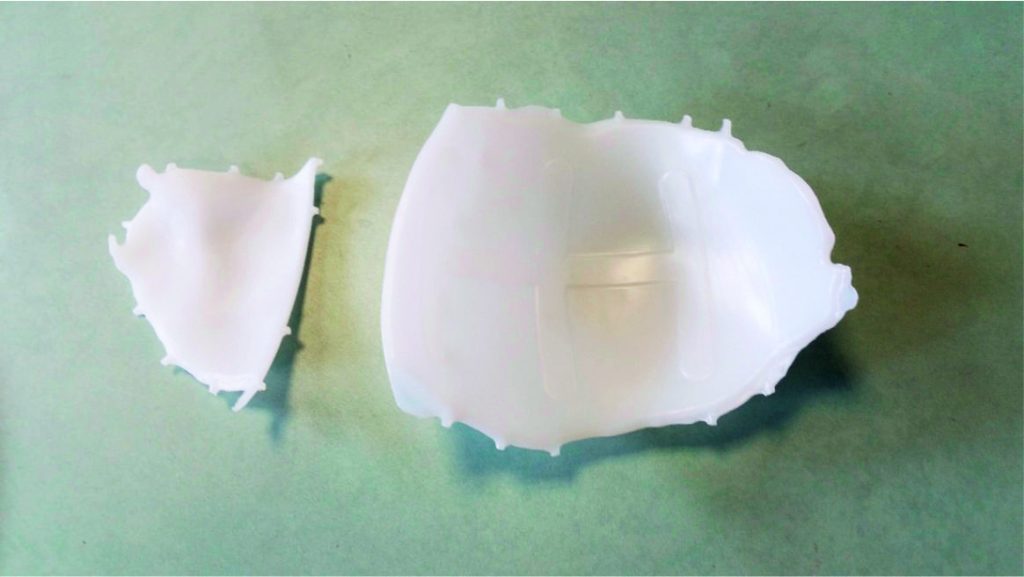

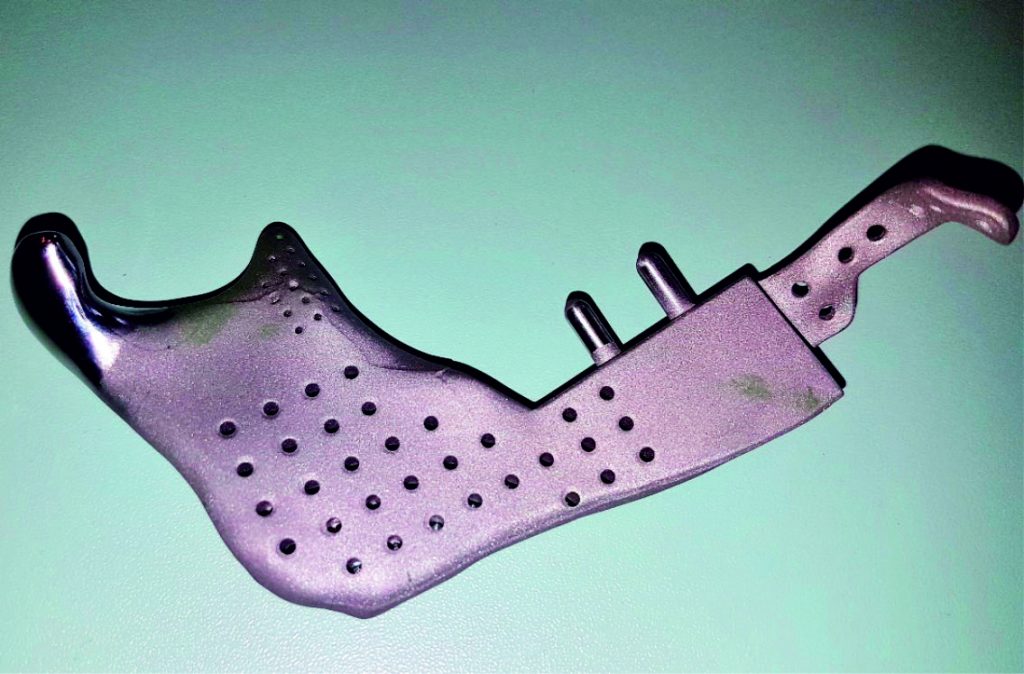

The latest production offerings of PFN PAFANA S.A. are individual medical implants for humans and animals.

The engineers from the Product Development Department of the Pabianice Tool Factory PAFANA S.A. have developed a unique technology of the efficient manufacture of individual facio-cranial medical implants. The individual implants are designed for a specific patient who was injured in an accident or whose facio-cranial bones were amputated as a result of neoplastic lesions. The reconstructed organ is designed by specialists using professional graphics software on the basis of the computer tomography’s records of the patient’s healthy and damaged bones. The verified model of the implant is 3D printed and accepted by a surgeon.

Implants are made on the latest generation Laser 1300 Da Vinci hybrid machine – machining and laser processing on one CNC machine. The use of the latest technology and the highest quality materials allows us to obtain implants with the highest spectrum of applications in medical implantology. These are development activities in the field of new technologies as well as focused on the social role of this type of products.

A team of PAFANA S.A. technologists and programmers makes a ready implant of medical materials: Chirulen medical polyethylene or Ti6Al4V-5ELI medical titanium alloy.

Now the manufacturing technology of three types of implants is mastered:

1.Implant of cranial plate “Cranioplasty” – made of Chirulen plastic.

2.Implant of orbital cavity “Orbit” – made of Chirulen plastic.

3.Implant of mandible “Mandible” – made of Ti6Al4V 5ELI medical titanium alloy.

4.Implant of mandible (placed in the 3D skull model).

We would like to encourage you to take advantage of our offer regarding the use of efficient 2D and 3D laser treatment. We have an opportunity to use a fibre laser with the output of up to 3kW and a pulsed laser with the output of up to 12 kW.

The advantages of the technology are:

– faster and cheaper machining,

– precise technology of drilling, cutting and welding on a single machine,

– contact-free treatment,

– possibility of cutting of very thin materials,

– cutting of even very small and complicated shapes in 3, 4 and 5-axes,

– work in very hard materials.

MACHINING METHODS USING THE LASER TECHNOLOGY PERFORMED IN PAFANA S.A.

TYPE OF MACHINING:

DRILLING OF HOLES: min. diameter ø 0.05 mm.

CUTTING: max. depth 5 mm.

WELDING:

min. depth of weld:

fibre laser 0.25 mm

pulsed laser 2.5 mm.

MACHINED MATERIALS:

Steels

Cast irons

Non-ferrous metals

Heat resistant alloys

Hard and super

hard materials

(including TITANIUM and its alloys).

Our experts will help you select the proper laser technology which makes it possible to increase efficiency and quality of the product while reducing the cost of its manufacture at the same time. The offer also includes the support in identifying the products whose current manufacture can be changed into the laser technology.

Examples of details made by the laser technology:

Drilling of holes in the cone type filter – 2301 holes ø 0.3÷0.03

Cutting of shape and holes in the electric panel – 321 holes ø 0.55±0.05

Drilling of holes in the filter – 163 holes ø 0.45±0.05

Precise 4-axis welding of the medical implant.

see the PAFANA on-line catalog: http://pafana.elkat.eu/#0

see the assortment of the PAFANA catalog edition 07/2020: https://pafana.pl/en/products/laser-technology-pafana-machining-methods-using-the-laser-technology-performed-in-pafana-type-of-machining-drilling-of-holes-possibilities-min-diameter-o0-05-mm-machined-materials-steels-medical-impla/

see PAFANA news: https://pafana.pl/en/products/new/

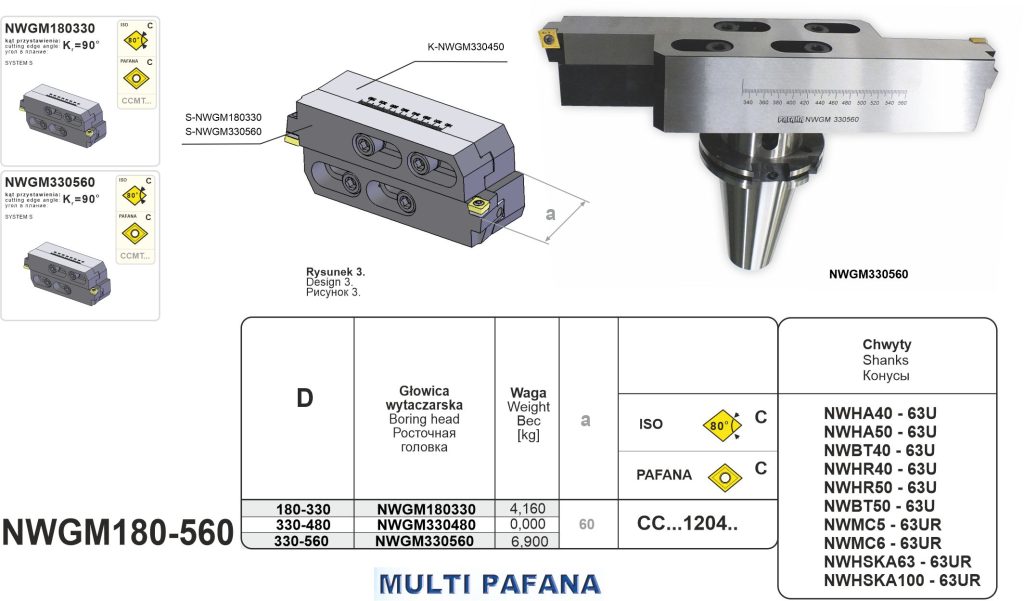

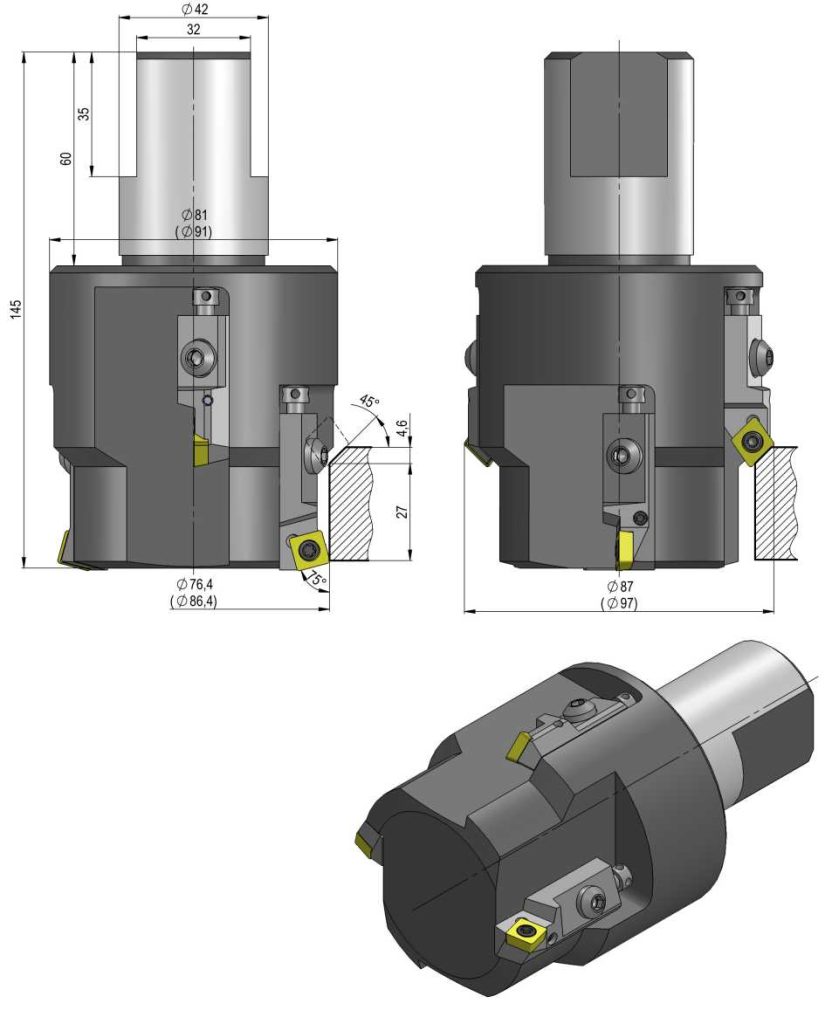

BORING MODULAR SYSTEM “MULTI PAFANA” – THE LARGEST BORING RANGES.

Boring modular system “MULTI PAFANA” covers boring ranges from 10 mm to 560 mm.

We have already presented the NWGW10150 versatile medium boring bars with ranges from 10 mm to 150 mm and the NWGW10300 with ranges from 10 mm to 300 mm. It’s time to present PAFANA boring bars with large machining ranges – roughing and finishing.

I.ROUGHING MACHINING.

1.NWGM180-560 – twin edge boring tool NWGU… for roughing machining of holes with diameters from 180 to 560 mm.

ASSORTMENT:

NWGM180330

NWGM330480

NWGM330560

PAFANA INSERTS CC…1204..:

CCMT 120404 SSP BP30S (P), FM30S (M),

CCMT 120408 SSP BP30S (P), FM30S (M),

CCMT 120404 SS BP30A (P), BP35A (P),

CCMT 120408 SS BP30A (P), BP35A (P),

CCMT 120408 SW1 BP35A (P),

CCGT120402 FN-AP NK10 (K(N),

CCGT120404 FN-AP NK10 (K(N),

CCGT120408 FN-AP NK10 (K(N),

CCGT120404 FN-AL NK15A (K(N),

CCGT120408 FN-AL NK15A (K(N).

SHANKS:

NWHA40 – 63U,

NWHA50 – 63U,

NWBT40 – 63U,

NWHR40 – 63U,

NWHR50 – 63U,

NWBT50 – 63U,

NWMC5 – 63UR,

NWMC6 – 63UR,

NWHSKA63 – 63UR,

NWHSKA100 – 63UR.

As you can see, the range of boring capabilities 180-560 is divided into three boring tools 180-330, 330-480, 330-560, which additionally gives this set the versatility of mounting it on multi-task shanks for machining on conventional and numerically controlled CNC machines.

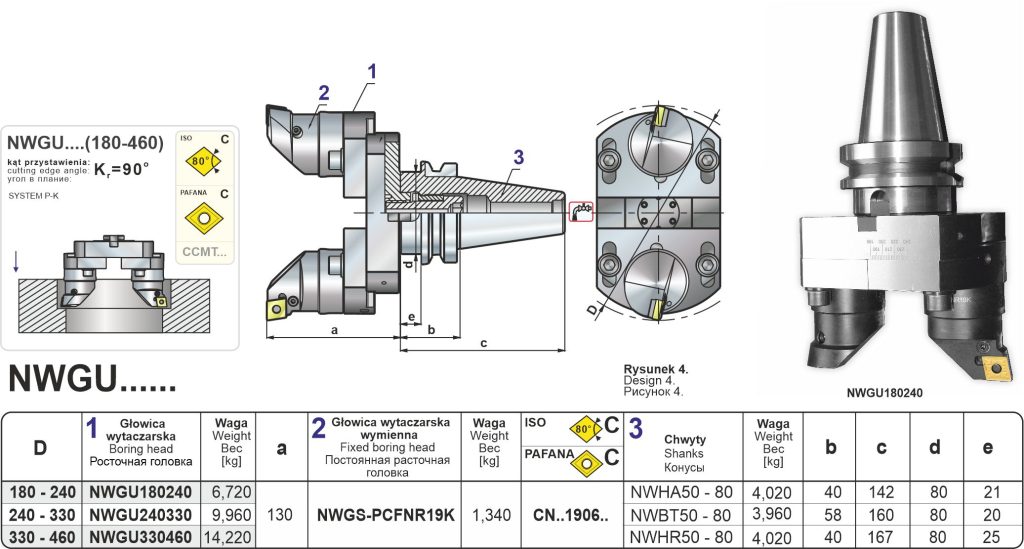

2.NWGU180-460 – twin edge boring tool NWGU… for roughing machining of holes with diameters from 180 to 460 mm.

ASSORTMENT:

NWGU180240

NWGM240330

NWGM330460

PAFANA INSERTS CN…1906..:

CNMG 190612 ZSP BP30S (P), BP35S (P), BK20S (K), BK10S (K),

CNMG 190616 ZSP BP30S (P), BP35S (P), BK20S (K), BK10S (K),

CNMM 190612 ZS BP30A (P), BP35A (P),

CNMM 190616 ZS BP30A (P), BP35A (P),

CNMM 190616 SN-ZS1 BP30A (P), BP35A (P),

CNMM 190624 SN-ZS1 BP30A (P),

CNMM 190612 EN-ZS5 BP20S (P), BP30S (P), BP35S (P),

CNMM 190616 EN-ZS5 BP20S (P), BP30S (P), BP35S (P),

CNMA 190612 BP20S (P), BK20S (K),

CNMA 190612 BP20S (P), BK20S (K),

SHANKS:

NWHA50 – 80

NWBT50 – 80

NWHR50 – 80

Also, this set for boring 180-460 is divided into three boring tools 180-240, 240-330, 330-460, which additionally gives the set the versatility of mounting on multi-task shanks for machining on conventional and numerically controlled CNC machines.

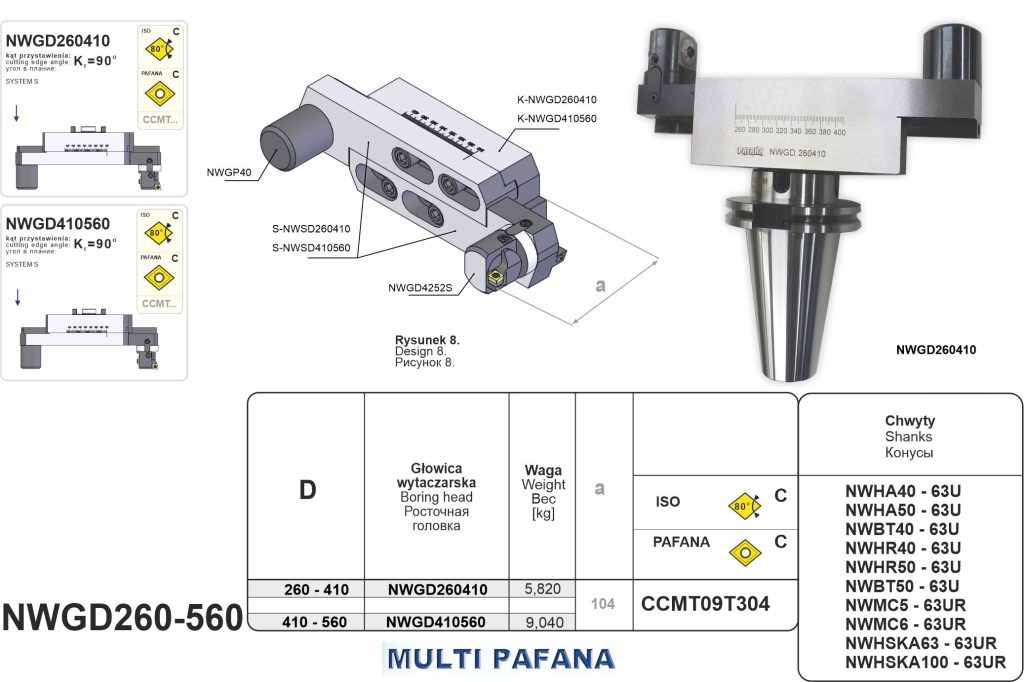

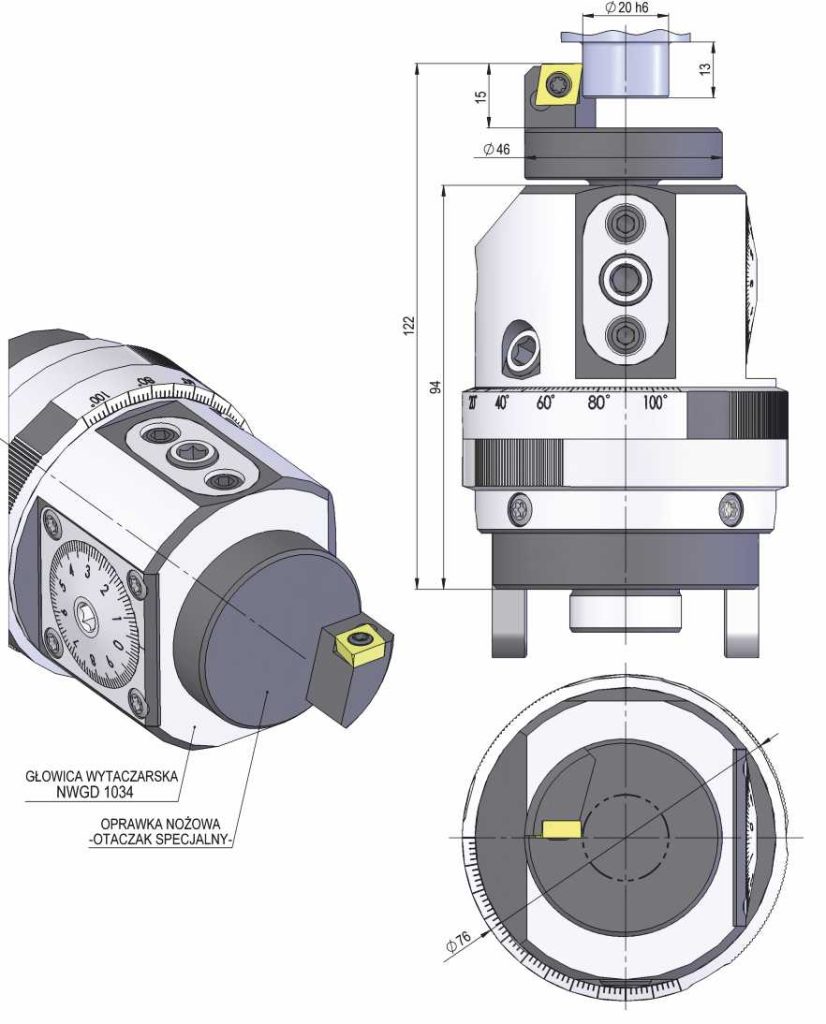

II.FINISHING MACHINING – precision of adjustment 0.01 mm per diameter.

1.NWGD260-560- twin edge boring tool NWGD…. for finishing machining of holes with diameters from 260 mm to 560 mm.

ASSORTMENT:

NWGD260410

NWGD410560

PAFANA INSERTS CCMT09T304:

CCMT09T304 DS1 CRP10A (P),

CCMT09T304 SDS BP20S (P), BP30S (P),

CCMT09T304 SSP BP20S (P), BP30S (P), BP35S (P), FM30S (M), BK20S (K),

CCMT09T304 SS BP20S (P), BP20A (P), BP35A (P),

CCMT09T304 SW1 BP20S (P), BP20A (P), BP35A (P).

SHANKS:

NWHA40 – 63U,

NWHA50 – 63U,

NWBT40 – 63U,

NWHR40 – 63U,

NWHR50 – 63U,

NWBT50 – 63U,

NWMC5 – 63UR,

NWMC6 – 63UR,

NWHSKA63 – 63UR,

NWHSKA100 – 63UR.

The range of boring capabilities 260-560 is divided into two boring tools 260-410, 410-560, which additionally gives the universality of this set with the possibility of mounting it on multi-task shanks for machining on conventional and numerically controlled CNC machines.

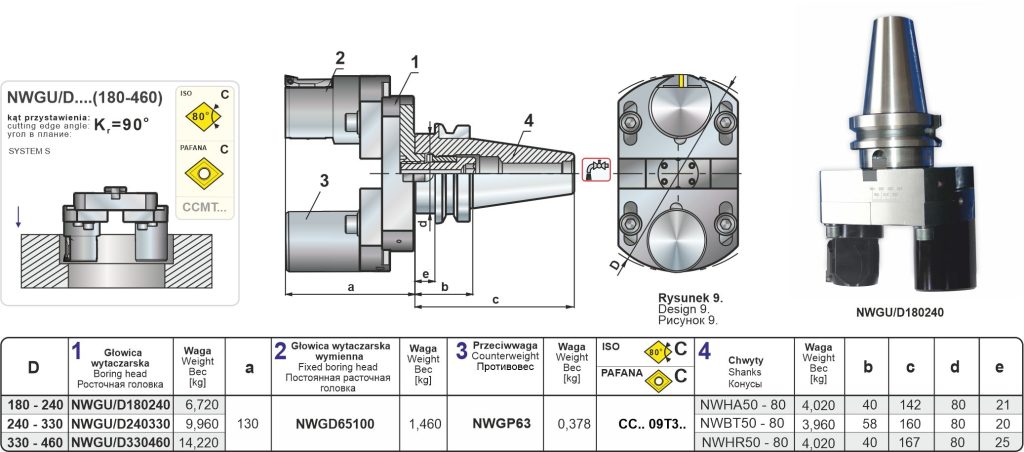

2.NWGU/D180-460 – twin edge boring tool NWGU/D…. for finishing machining of holes with diameters from 180 mm to 460 mm.

ASSORTMENT:

NWGU/D180240,

NWGU/D240330,

NWGU/D330460.

PAFANA INSERTS CC…09T3..:

CCMT09T304 DS1 CRP10A (P),

CCMT09T302 SDS BP30S (P), FM30S (M),

CCMT09T304 SDS PB30S (P), BP30S (P), FM30S (M),

CCMT09T308 SDS PB30S (P), BP30S (P), BP35S (P), FM30S (M),

CCMT09T304 SS PB30A (P), BP35A (P),

CCMT09T308 SS PB30A (P), BP35A (P),

CCMT09T304 SW1 PB30A (P), BP35A (P),

CCMT09T308 SW1 PB30A (P), BP35A (P),

CCGT09T300 DD FM20S (M),

CCGT09T301 DD FM20S (M),

CCGT09T302 FN-AP NK10A (K(N)),

CCGT09T304 FN-AP NK10A (K(N)),

CCGT09T308 FN-AP NK10A (K(N)),

CCGT09T302 FN-AL NK15A (K(N)),

CCGT09T304 FN-AL NK15A (K(N)),

CCGT09T308 FN-AL NK15A (K(N)).

SHANKS:

NWHA50-80,

NWBT50-80,

NWHR50-80.

As in the roughing set, this set for finishing boring 180-460 is divided into three boring tools 180-240, 240-330, 330-460, which additionally gives the set versatility with the possibility of mounting on multi-purpose shanks for machining on conventional and numerically controlled CNC machines.

see the PAFANA on-line catalog: http://pafana.elkat.eu/#0

see the assortment of the PAFANA catalog edition 07/2020: https://pafana.pl/en/products/boring-bars-of-pafana-boring-modular-system-multi-pafana/

see PAFANA news: https://pafana.pl/en/products/new/

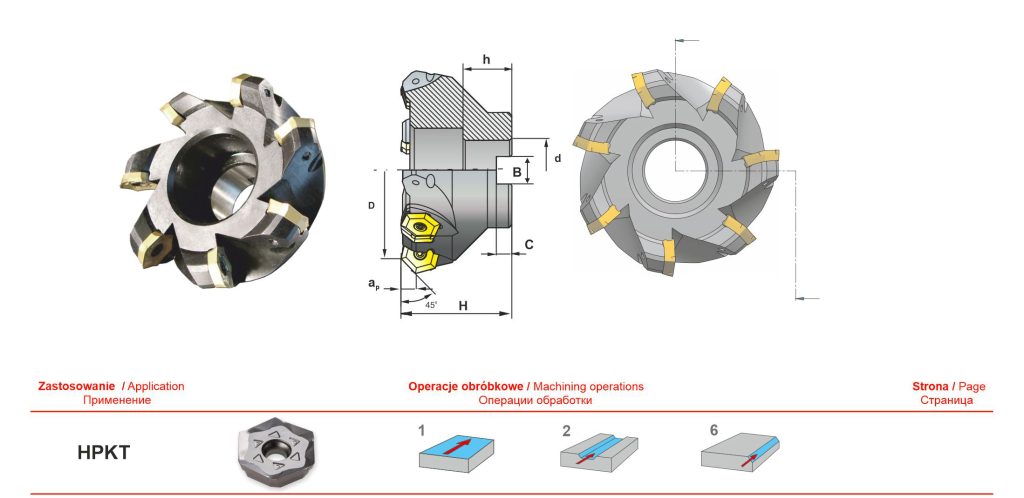

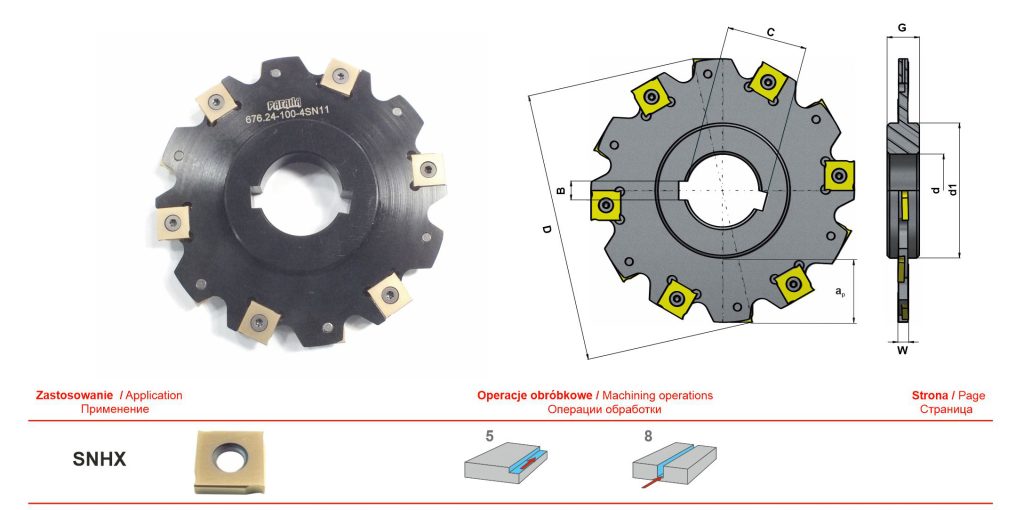

MILLING CUTTERS FOR NON-STANDARD (NON-ISO) INSERTS – PFN PAFANA S.A.

Milling cutters are extremely important tools for use in milling processes on conventional and CNC milling machines.

PFN PAFANA S.A. offers milling cutters for both standard (ISO) and non-standard (non-ISO) inserts.

Non-standard milling inserts in PAFANA’s offer and milling cutters for these inserts:

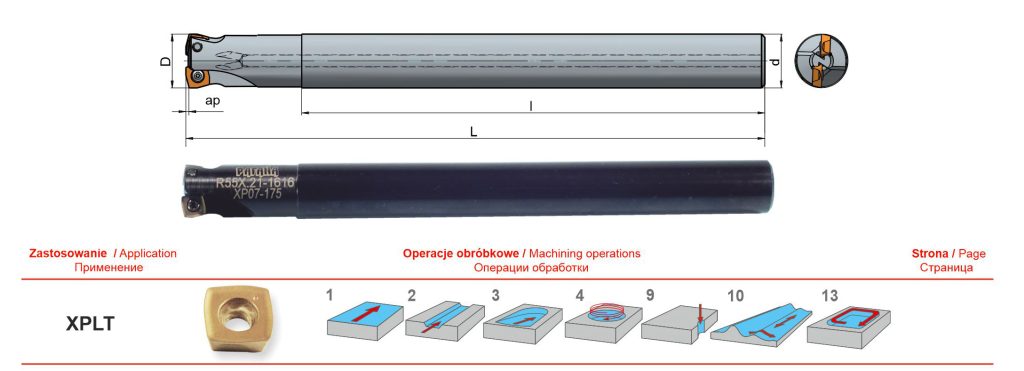

1.HPCTurbo – high performance milling inserts with high feed rates

– XPLT 070305 (Κr =25°) – slot and end mills R55X.21-…XP07…,

MACHINING OPERATIONS: 1 – FACE MILLING, 2 – SLOT MILLING, 3 – ANGLED MILLING, 4 – HELICAL PLUNGING, 9 – PLUNGE MILLING, 10 – PROFILE MILLING, 13 – POCKET MILLING.

ASSORTMENT:

R55X.21-1616XP07-175

R55X.21-2020XP07-200

R55X.21-2525XP07-225

PAFANA INSERT:

XPLT 070305

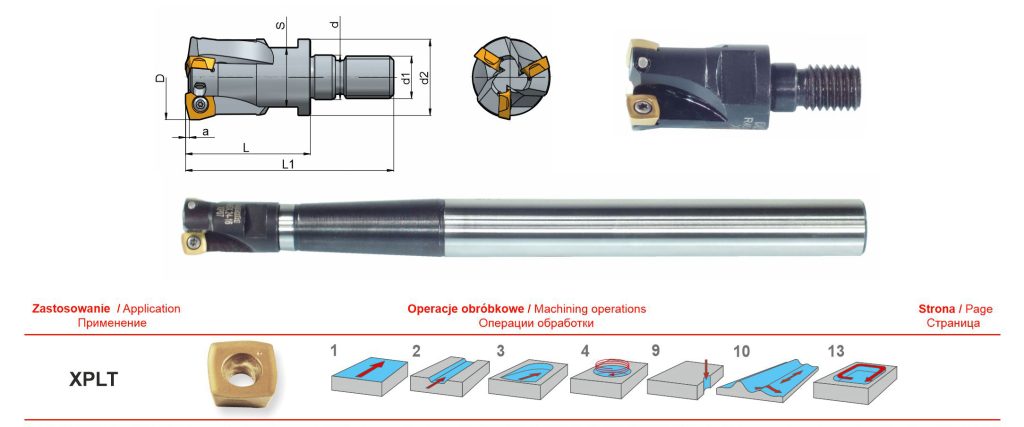

– screwed shank milling cutters R45X.24-…XPO07….

MACHINING OPERATIONS: 1 – FACE MILLING, 2 – SLOT MILLING, 3 – ANGLED MILLING, 4 – HELICAL PLUNGING, 9 – PLUNGE MILLING, 10 – PROFILE MILLING, 13 – POCKET MILLING.

R45X.24-…XPO07….

ASSORTMENT:

R45X.24-16XP07

R45X.24-20XP07

PAFANA INSERT:

XPLT 070305

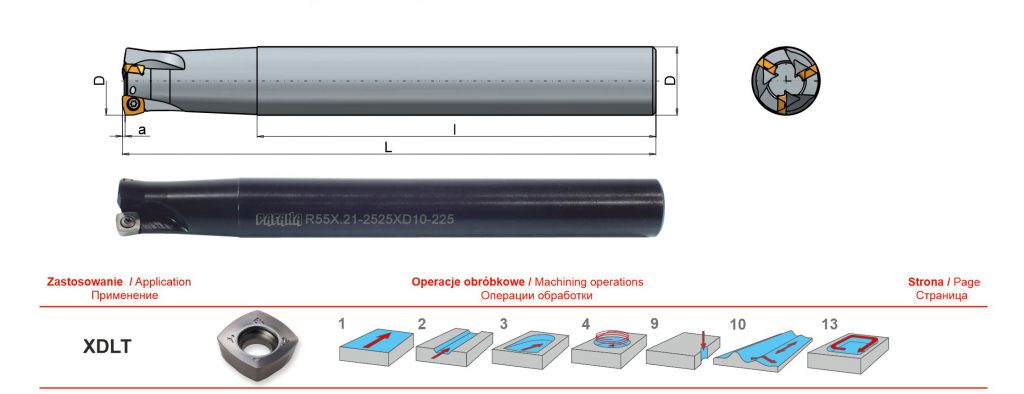

– XDLT 10T308 (Κr =25°) – slot and end mills R55X.21-…XD10…,

MACHINING OPERATIONS: 1 – FACE MILLING, 2 – SLOT MILLING, 3 – ANGLED MILLING, 4 – HELICAL PLUNGING, 9 – PLUNGE MILLING, 10 – PROFILE MILLING, 13 – POCKET MILLING.

ASSORTMENT:

R55X.21-2525XD10-225

R55X.21-3232XD10-250

R55X.21-2525XD10

R55X.21-3232XD10

PAFANA INSERT:

XDLT 10T308

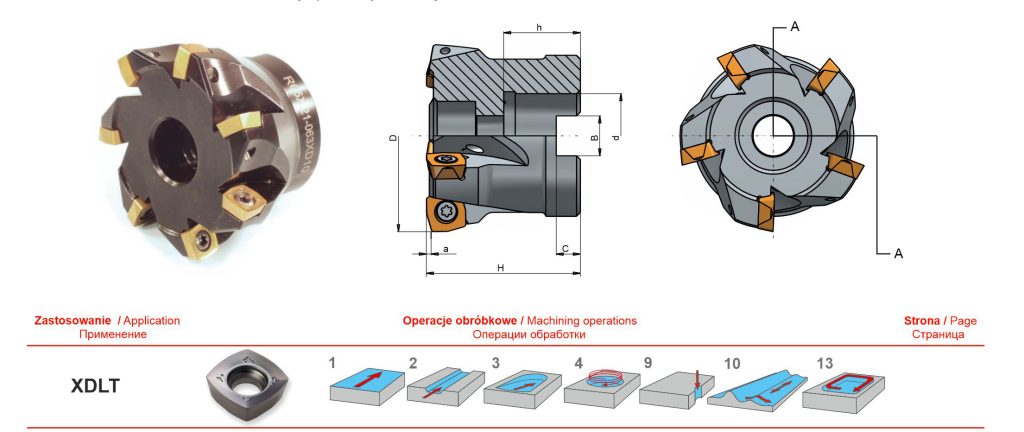

– face milling cutters R65X.21-…XD10

MACHINING OPERATIONS: 1 – FACE MILLING, 2 – SLOT MILLING, 3 – ANGLED MILLING, 4 – HELICAL PLUNGING, 9 – PLUNGE MILLING, 10 – PROFILE MILLING, 13 – POCKET MILLING.

ASSORTMENT:

R65X.21-040XD10

R65X.21-050XD10

R65X.21-063XD10

R65X.21-080XD10

R65X.21-100XD10

PAFANA INSERT:

XDLT 10T308

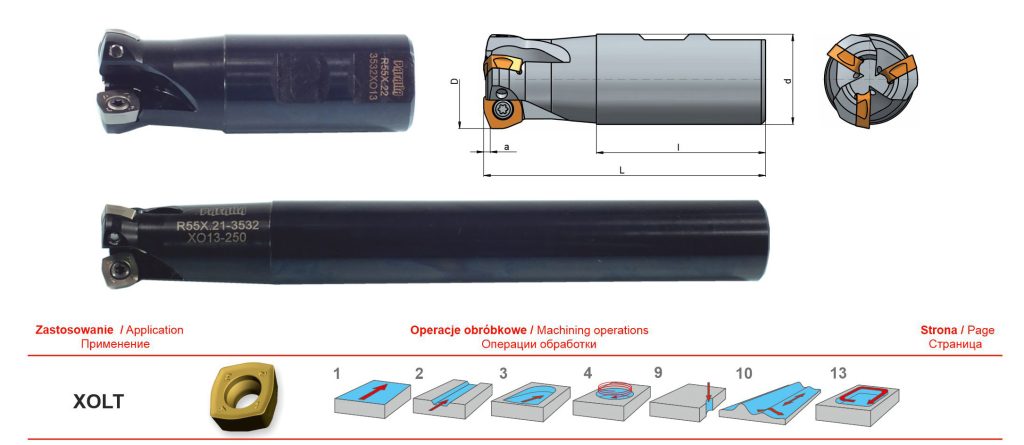

– XOLT 130410 (Κr =25°) – slot and end mills R55X.22-3532X013…,

MACHINING OPERATIONS: 1 – FACE MILLING, 2 – SLOT MILLING, 3 – ANGLED MILLING, 4 – HELICAL PLUNGING, 9 – PLUNGE MILLING, 10 – PROFILE MILLING, 13 – POCKET MILLING.

ASSORTMENT:

R55X.22-3532XO13

R55X.21-3532XO13-250

PAFANA INSERT:

XOLT 130410

– face milling cutters R65X.21-…XO13.

MACHINING OPERATIONS: 1 – FACE MILLING, 2 – SLOT MILLING, 3 – ANGLED MILLING, 4 – HELICAL PLUNGING, 9 – PLUNGE MILLING, 10 – PROFILE MILLING, 13 – POCKET MILLING.

ASSORTMENT:

R65X.21-050XO13

R65X.21-063XO13

R65X.21-080XO13

R65X.21-100XO13

PAFANA INSERT:

XOLT 130410

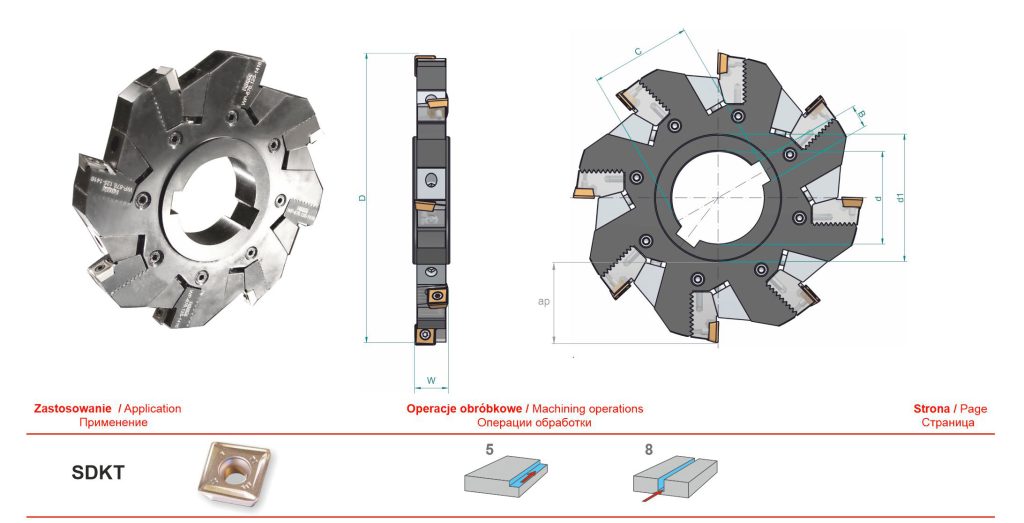

2.SDKT 09T3…(Κr =90°) – grooving milling cutters, three – sided, adjustable 676.24-

MACHINING OPERATIONS: 5 – SHOULDER MILLING, 8 – SLOT MILLING.

ASSORTMENT:

676.24-125-1416

676.24-200-1416

676.24-250-1416

676.24-315-1416

PAFANA INSERT:

SDKT 09T3

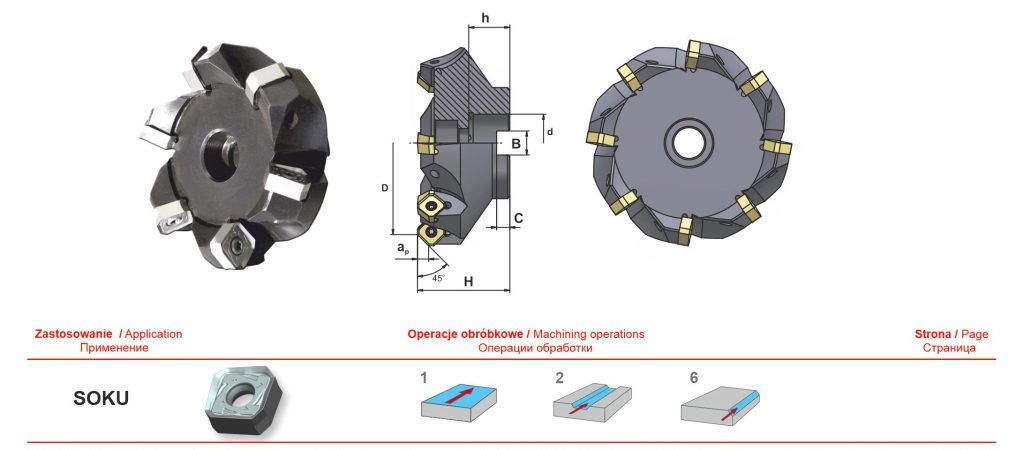

3.SOKU 1205, 1505 (Κr =45°) – face milling cutters R646…-…SOKU

MACHINING OPERATIONS: 1 – FACE MILLING, 2 – SLOT MILLING, 6 – CHAMFERING.

ASSORTMENT:

R646.21-40SOKU12

R646.21-50SOKU12

R646.21-63SOKU12

R646.21-063 SOKU

R646.22-080 SOKU

R646.22-100 SOKU

R646.22-125 SOKU

R646.23-160 SOKU

R646.23-200 SOKU

R646.23-250 SOKU

R646.23-315 SOKU*

R646.23-350 SOKU*

* – frezy na specjalne zamówienie / milling cutters on special order /

PAFANA INSERT:

SOKU 1205

SOKU 1505

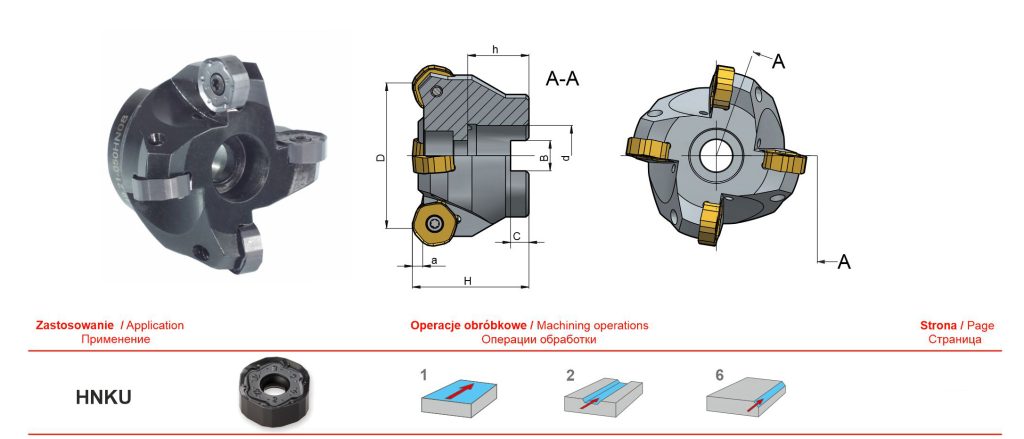

4.HNKU 0806 (Κr =45°) – face milling cutters R649.21-…HN08

MACHINING OPERATIONS: 1 – FACE MILLING, 2 – SLOT MILLING, 6 – CHAMFERING.

ASSORTMENT:

R649.21-040HN08

R649.21-050HN08

R649.21-063HN08

R649.21-080HN08

R649.21-100HN08

R649.21-125HN08

PAFANA INSERT:

HNKU 0806

5.HPKT 0604 (Κr =45°) – face milling cutters R649…-…HPKT

MACHINING OPERATIONS: 1 – FACE MILLING, 2 – SLOT MILLING, 6 – CHAMFERING.

ASSORTMENT:

R649.21-050

R649.21-063

R649.22-080

R649.22-100

PAFANA INSERT:

HPKT 0604

6.SNHX 1102 (1203) (1205) (Κr =90°) – metal slitting saw with SNHX inserts for slot

milling and parting 676.24-100-4SN11.

MACHINING OPERATIONS: 5 – SHOULDER MILLING, 8 – SLOT MILLING.

ASSORTMENT:

676.24-100-4SN11

676.24-125-4SN11

676.24-160-4SN11

676.24-100-6SN12

676.24-125-6SN12

676.24-100-10SN12

676.24-125-10SN12

PAFANA INSERT:

SNHX 1102 (1203) ( 1205).

The gallery is as impressive in its images as it is in its machining capabilities. The indexable inserts, the fixtures durable and proven in machining.

To think how much certainty this brings to production planning and machining realisations.

see the PAFANA on-line catalog: http://pafana.elkat.eu/#0

see the assortment of the PAFANA catalog edition 07/2020: https://pafana.pl/en/products/milling-cutters-of-pafana-possible-applications-face-milling-slot-milling-angled-milling-helical-plunging-shoulder-milling-chamfering-axial-plunging-slot-milling-plunge-milling-profile-milling-periphe/

see PAFANA news: https://pafana.pl/en/products/new/

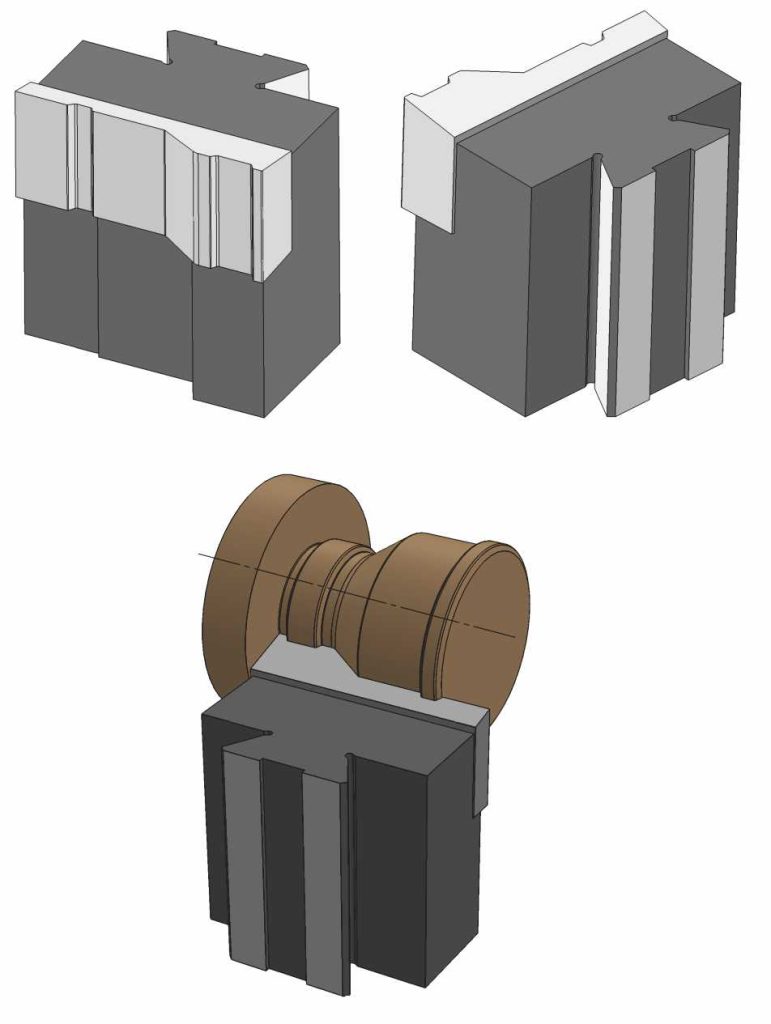

SPECIAL TOOLS – PFN PAFANA S.A.

ONE OF THE IMPORTANT AREAS OF ACTIVITY OF PFN PAFANA S.A. IS THE DESIGN AND PRODUCTION OF SPECIAL TOOLS.

SPECIAL TOOLS BY PAFANA ARE MADE ON THE BASIS OF CUSTOMER DRAWINGS OR THE MACHINING PROCESS NEEDED BY THE CUSTOMER. THEN THERE ARE ALMOST FANTASTIC “CREATIONS” ON THE COMPUTERS OF OUR ENGINEERS.

The latest example is spectacular in use, versatile, fantastic in form:

– milling cutter with mechanically fastened inserts – “ball”.

The cutter is designed for efficient copy milling on CNC machines – shaped and irregular internal surfaces.

The possibility of mounting cutting inserts intended for machining various materials gives the possibility of machining steel, non-ferrous metals and non-metals.

We have a milling tool at our disposal that allows you to efficiently remove redundant material in a short time.

Special geometry – the design allows you to work with low cutting resistance – this advantage allows you to work on long “overhangs”.

See for yourself, something fantastic: ” BALL CUTTER – PAFANA”

The presented cutter is without indexable inserts installed, the inserts are mounted in visible sockets with holes for mounting screws – insert mounting system – S.

The wide spectrum of special tools illustrates how effective these tools are and what a wide machining area PAFANA provides to its customers.

Below are examples of targeted PAFANA specialist tools:

1.Special turning tools with brazed insert made of sintered carbides.

2.Special toolholders with removable mechanically fixed indexable inserts.

3.Special rotary turning tools with brazed insert made of sintered carbides.

4.Special rotary tools with removable mechanically fixed indexable inserts.

5.Special boring bars, turning bars.

6.Special task tools.

THESE ARE TECHNICALLY ADVANCED TOOLS THAT MEET ALL THE CRITERIA OF THE DEVELOPING MARKET OF MODERN MACHINING.

IT IS A STRONGLY DEVELOPING TOOL MARKET.

see the PAFANA on-line catalog: http://pafana.elkat.eu/#0

see the assortment of the PAFANA catalog edition 07/2020: https://pafana.pl/en/products/pafana-special-tools/

see PAFANA news: https://pafana.pl/en/products/new/

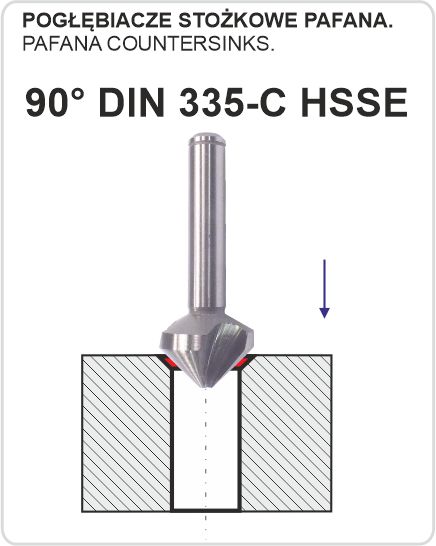

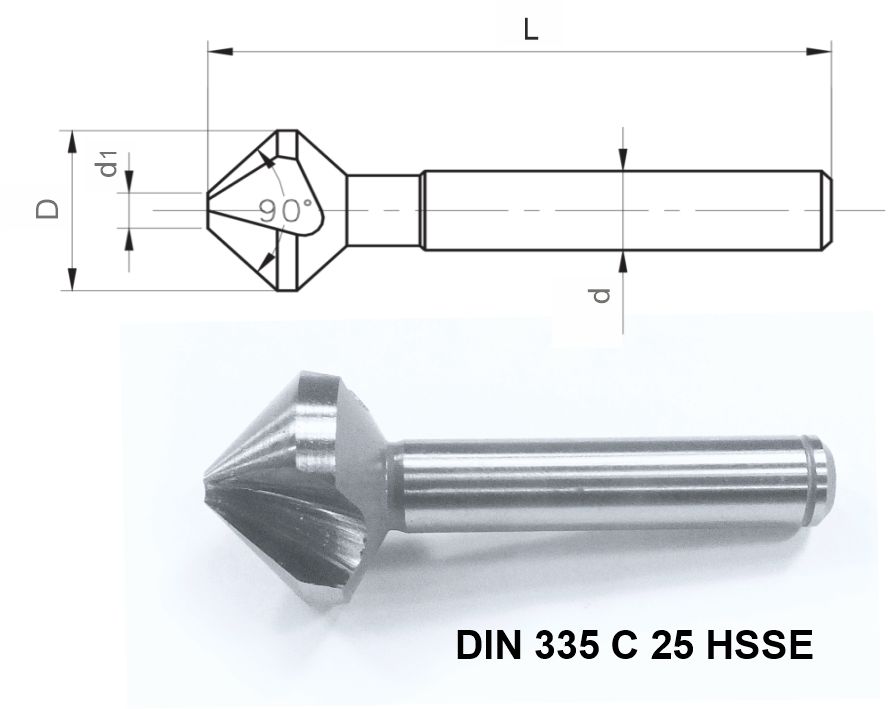

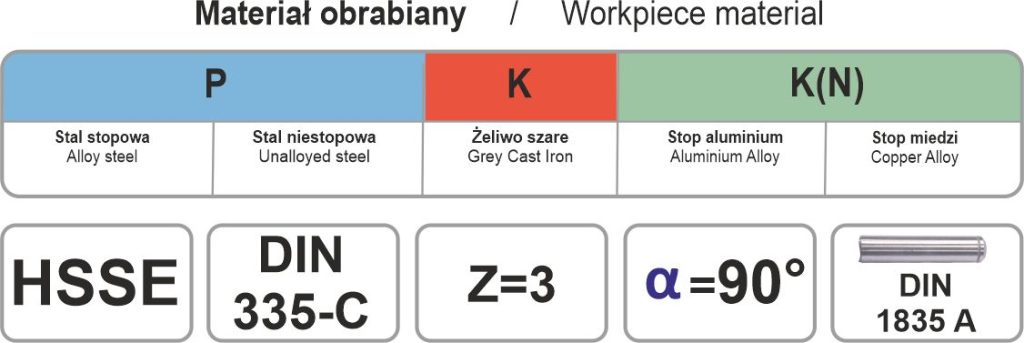

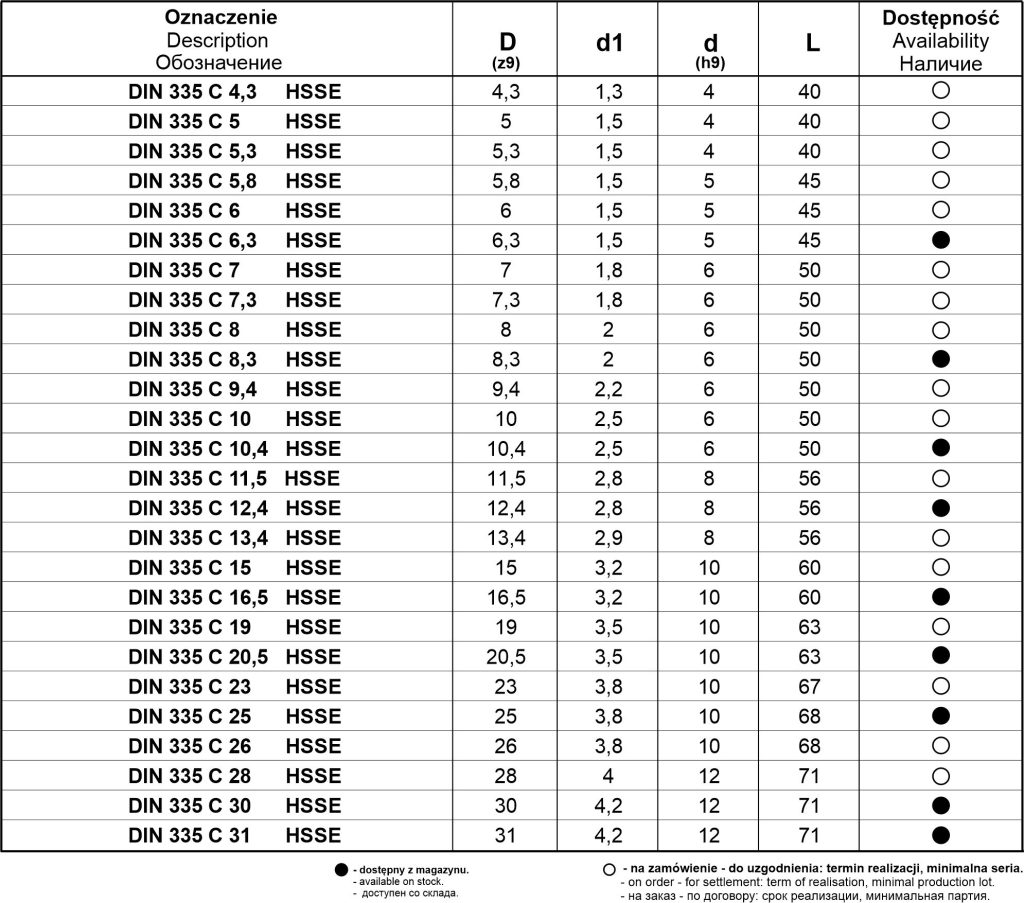

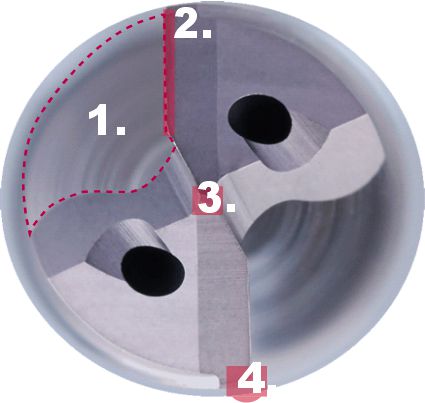

PAFANA COUNTERSINKS.

PFN PAFANA S.A. OFFERS 3-FLUTE COUNTERSINKS PLAIN SHANK. HSSE, DIN335-C, SHANK DIN1835A.

3 – FLUTE COUNTERSINKS PLAIN SHANK.

DIN 335-C HSS. NUMBER OF BLADES – Z=3. α=90°. SHANK – DIN 1835 A. WORKPIECE MATERIAL: P, K, K(N).

DIN 335 C 4,3 HSSE

DIN 335 C 5 HSSE

DIN 335 C 5,3 HSSE

DIN 335 C 5,8 HSSE

DIN 335 C 6 HSSE

DIN 335 C 6,3 HSSE

DIN 335 C 7 HSSE

DIN 335 C 7,3 HSSE

DIN 335 C 8 HSSE

DIN 335 C 8,3 HSSE

DIN 335 C 9,4 HSSE

DIN 335 C 10 HSSE

DIN 335 C 10,4 HSSE

DIN 335 C 11,5 HSSE

DIN 335 C 12,4 HSSE

DIN 335 C 13,4 HSSE

DIN 335 C 15 HSSE

DIN 335 C 16,5 HSSE

DIN 335 C 19 HSSE

DIN 335 C 20,5 HSSE

DIN 335 C 23 HSSE

DIN 335 C 25 HSSE

DIN 335 C 26 HSSE

DIN 335 C 28 HSSE

DIN 335 C 30 HSSE

DIN 335 C 31 HSSE

see the PAFANA on-line catalog: http://pafana.elkat.eu/#0

see the assortment of the PAFANA catalog edition 07/2020: https://pafana.pl/en/pafana-countersinks/

see PAFANA news: https://pafana.pl/en/products/new/

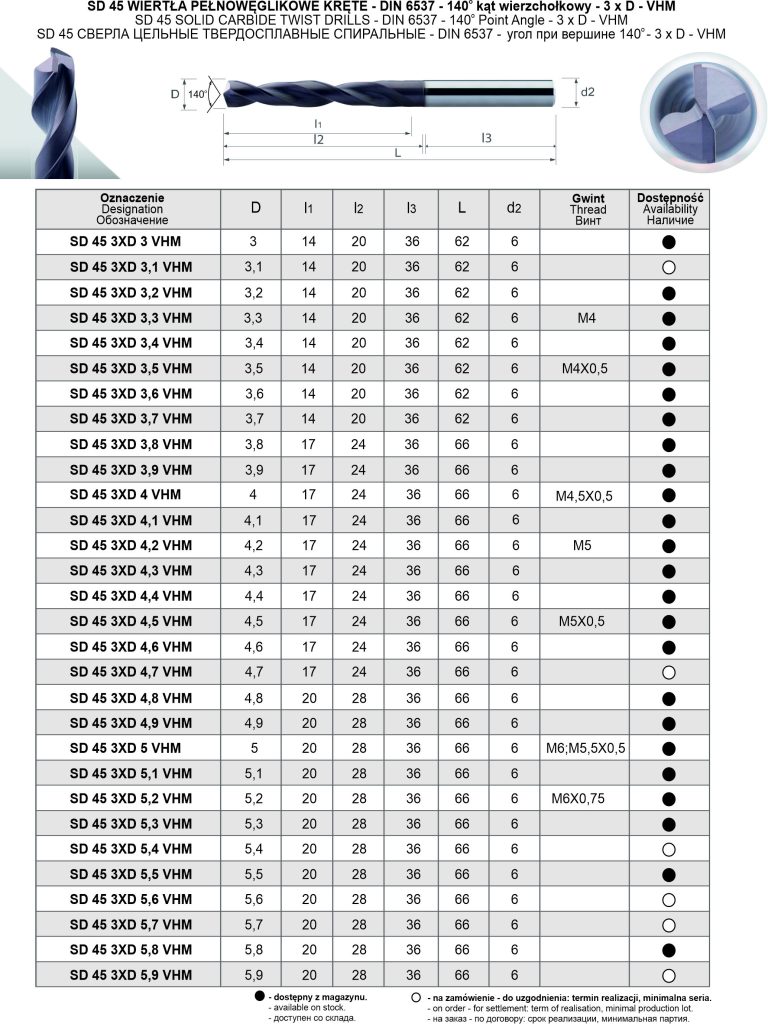

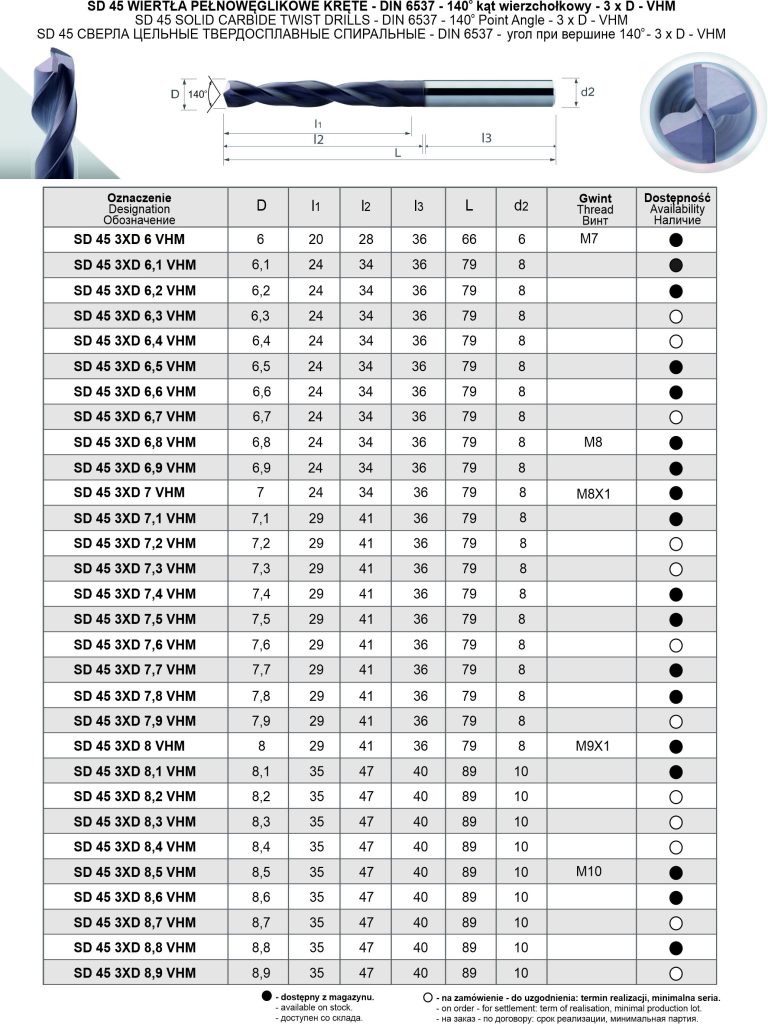

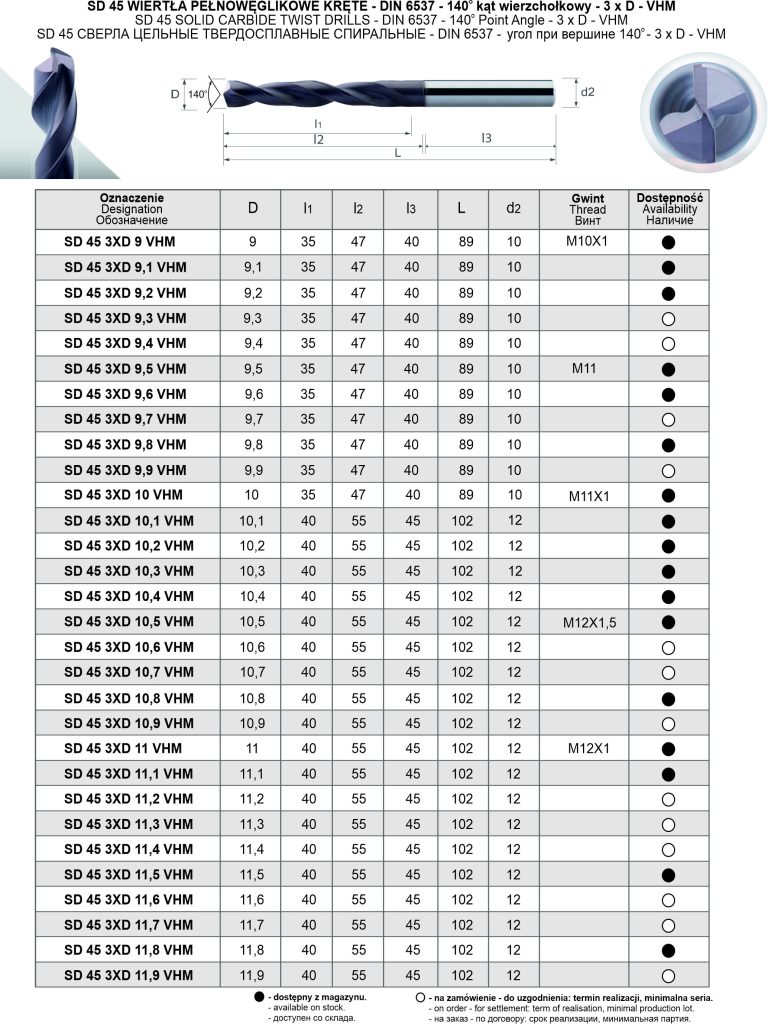

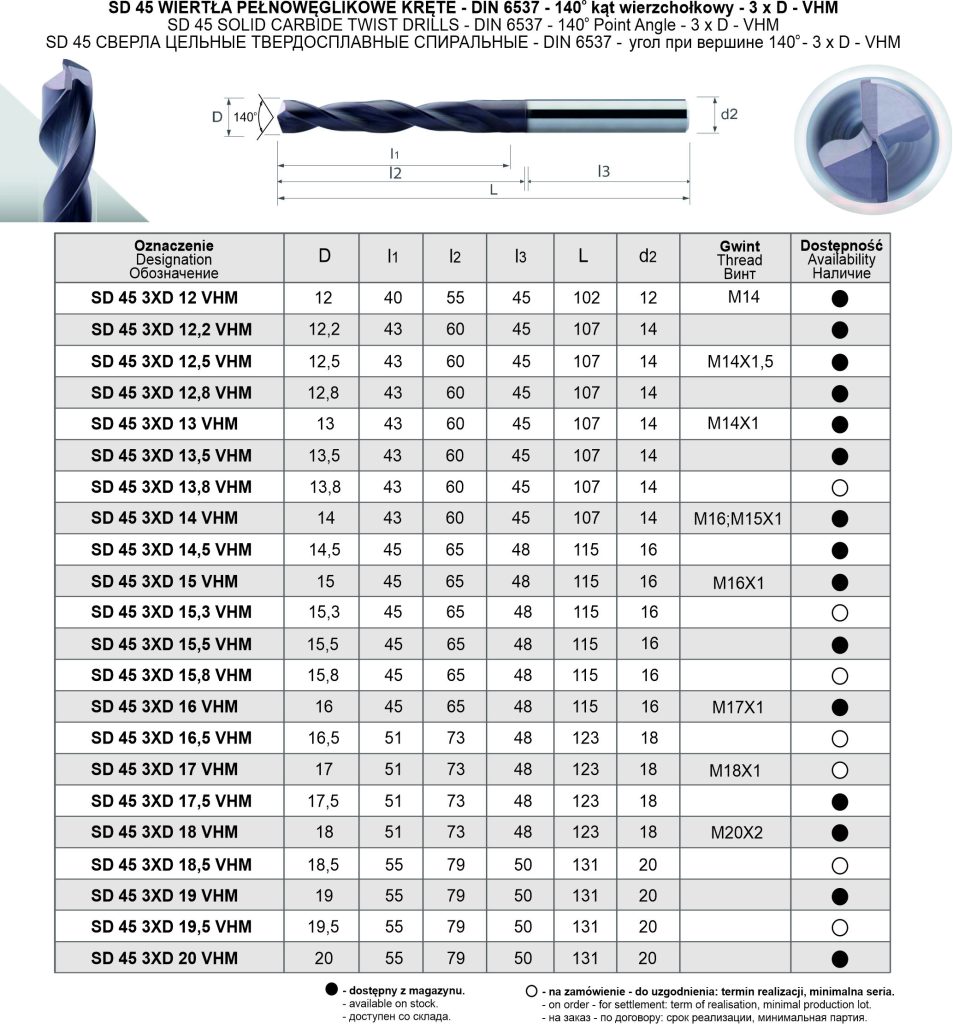

SD 45 SOLID CARBIDE TWIST DRILLS – “SMart Drills” PAFANA – DIN6537.

ADVANTAGES:

1. Wide chip pocket. Enhances and smoother chip evacuation.

2. Straight Edge Profile. Short chip and reinforced cutting edge.

3. Larger K-value (at the tip of the drill).

Suitable for higher feed rate and enhanced tool durability

4. Additional chamfer on the edge of the drill (corner of the drill).

Ideal for cast iron and very good surface finishing

5. Versatile. Suitable for 5 material groups.

- Carbon, alloy and prehardened steels.

- Stainless steels.

- Grey, ductile cast iron.

- Plastic, foundry aluminium, copper alloys.

- Nickel, titanium, cobalt alloys.

- Point angle 140°.

- Helix angle 30°.

AVAILABLE DRILLS – PAFANA “SMART DRILLS”:

3XD

SD 45 SOLID CARBIDE TWIST DRILLS – DIN 6537 – 140o Point Angle – 3 x D – VHM

SD 45 3XD 3 VHM

SD 45 3XD 3,1 VHM

SD 45 3XD 3,2 VHM

SD 45 3XD 3,3 VHM

SD 45 3XD 3,5 VHM

SD 45 3XD 3,6 VHM

SD 45 3XD 3,7 VHM

SD 45 3XD 3,8 VHM

SD 45 3XD 3,9 VHM

SD 45 3XD 4 VHM

SD 45 3XD 4,1 VHM

SD 45 3XD 4,2 VHM

SD 45 3XD 4,3 VHM

SD 45 3XD 4,4 VHM

SD 45 3XD 4,5 VHM

SD 45 3XD 4,6 VHM

SD 45 3XD 4,7 VHM

SD 45 3XD 4,8 VHM

SD 45 3XD 4,9 VHM

SD 45 3XD 5 VHM

SD 45 3XD 5,1 VHM

SD 45 3XD 5,2 VHM

SD 45 3XD 5,3 VHM

SD 45 3XD 5,4 VHM

SD 45 3XD 5,5 VHM

SD 45 3XD 5,6 VHM

SD 45 3XD 5,7 VHM

SD 45 3XD 5,8 VHM

SD 45 3XD 5,9 VHM

SD 45 3XD 6 VHM

SD 45 3XD 6,1 VHM

SD 45 3XD 6,2 VHM

SD 45 3XD 6,3 VHM

SD 45 3XD 6,4 VHM

SD 45 3XD 6,5 VHM

SD 45 3XD 6,6 VHM

SD 45 3XD 6,7 VHM

SD 45 3XD 6,8 VHM

SD 45 3XD 6,9 VHM

SD 45 3XD 7 VHM

SD 45 3XD 7,1 VHM

SD 45 3XD 7,2 VHM

SD 45 3XD 7,3 VHM

SD 45 3XD 7,4 VHM

SD 45 3XD 7,5 VHM

SD 45 3XD 7,6 VHM

SD 45 3XD 7,7 VHM

SD 45 3XD 7,8 VHM

SD 45 3XD 7,9 VHM

SD 45 3XD 8 VHM

SD 45 3XD 8,1 VHM

SD 45 3XD 8,2 VHM

SD 45 3XD 8,3 VHM

SD 45 3XD 8,4 VHM

SD 45 3XD 8,5 VHM

SD 45 3XD 8,6 VHM

SD 45 3XD 8,7 VHM

SD 45 3XD 8,8 VHM

SD 45 3XD 8,9 VHM

SD 45 3XD 9 VHM

SD 45 3XD 9,1 VHM

SD 45 3XD 9,2 VHM

SD 45 3XD 9,3 VHM

SD 45 3XD 9,4 VHM

SD 45 3XD 9,5 VHM

SD 45 3XD 9,6 VHM

SD 45 3XD 9,7 VHM

SD 45 3XD 9,8 VHM

SD 45 3XD 9,9 VHM

SD 45 3XD 10 VHM

SD 45 3XD 10,1 VHM

SD 45 3XD 10,2 VHM

SD 45 3XD 10,3 VHM

SD 45 3XD 10,4 VHM

SD 45 3XD 10,5 VHM

SD 45 3XD 10,6 VHM

SD 45 3XD 10,7 VHM

SD 45 3XD 10,8 VHM

SD 45 3XD 10,9 VHM

SD 45 3XD 11 VHM

SD 45 3XD 11,1 VHM

SD 45 3XD 11,2 VHM

SD 45 3XD 11,3 VHM

SD 45 3XD 11,4 VHM

SD 45 3XD 11,5 VHM

SD 45 3XD 11,6 VHM

SD 45 3XD 11,7 VHM

SD 45 3XD 11,8 VHM

SD 45 3XD 11,9 VHM

SD 45 3XD 12 VHM

SD 45 3XD 12,2 VHM

SD 45 3XD 12,5 VHM

SD 45 3XD 12,8 VHM

SD 45 3XD 13 VHM

SD 45 3XD 13,5 VHM

SD 45 3XD 13,8 VHM

SD 45 3XD 14 VHM

SD 45 3XD 14,5 VHM

SD 45 3XD 15 VHM

SD 45 3XD 15,3 VHM

SD 45 3XD 15,5 VHM

SD 45 3XD 15,8 VHM

SD 45 3XD 16 VHM

SD 45 3XD 16,5 VHM

SD 45 3XD 17 VHM

SD 45 3XD 17,5 VHM

SD 45 3XD 18 VHM

SD 45 3XD 18,5 VHM

SD 45 3XD 19 VHM

SD 45 3XD 19,5 VHM

SD 45 3XD 20 VHM

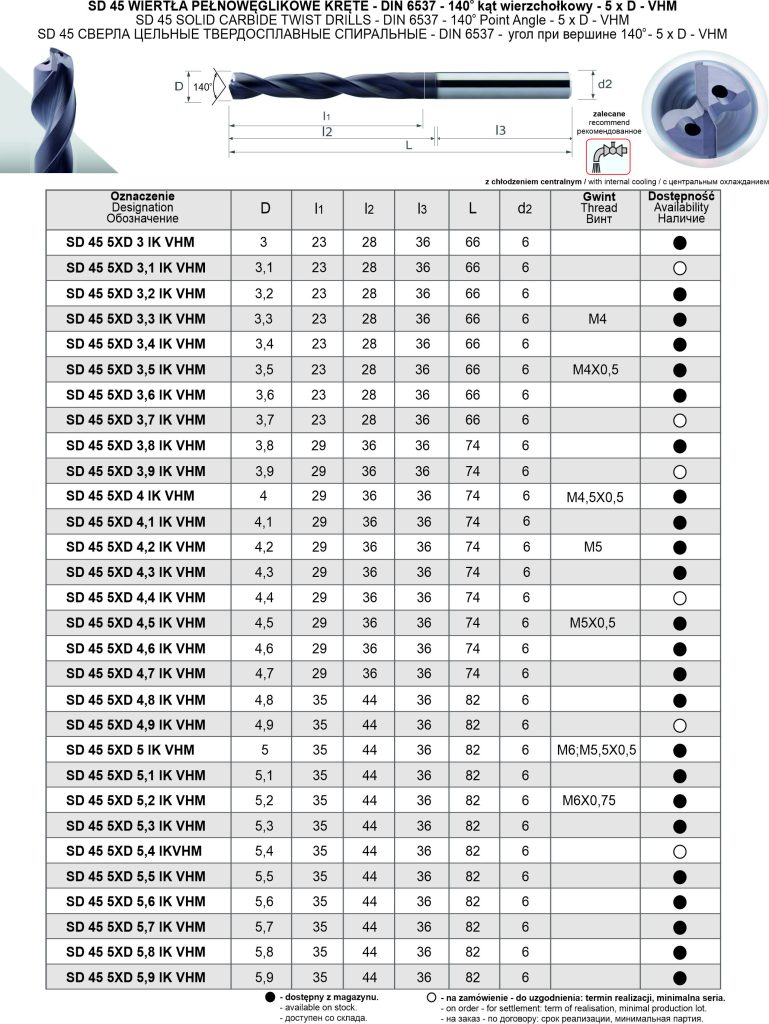

5XD WITH COOLANT.

SD 45 SOLID CARBIDE TWIST DRILLS – DIN 6537 – 140o Point Angle – 5 x D – VHM

SD 45 5XD 3 IK VHM

SD 45 5XD 3,1 IK VHM

SD 45 5XD 3,2 IK VHM

SD 45 5XD 3,3 IK VHM

SD 45 5XD 3,4 IK VHM

SD 45 5XD 3,5 IK VHM

SD 45 5XD 3,6 IK VHM

SD 45 5XD 3,7 IK VHM

SD 45 5XD 3,8 IK VHM

SD 45 5XD 3,9 IK VHM

SD 45 5XD 4 IK VHM

SD 45 5XD 4,1 IK VHM

SD 45 5XD 4,2 IK VHM

SD 45 5XD 4,3 IK VHM

SD 45 5XD 4,4 IK VHM

SD 45 5XD 4,5 IK VHM

SD 45 5XD 4,6 IK VHM

SD 45 5XD 4,7 IK VHM

SD 45 5XD 4,8 IK VHM

SD 45 5XD 4,9 IK VHM

SD 45 5XD 5 IK VHM

SD 45 5XD 5,1 IK VHM

SD 45 5XD 5,2 IK VHM

SD 45 5XD 5,3 IK VHM

SD 45 5XD 5,4 IKVHM

SD 45 5XD 5,5 IK VHM

SD 45 5XD 5,6 IK VHM

SD 45 5XD 5,7 IK VHM

SD 45 5XD 5,8 IK VHM

SD 45 5XD 5,9 IK VHM

SD 45 5XD 6 IK VHM

SD 45 5XD 6,1 IK VHM

SD 45 5XD 6,2 IK VHM

SD 45 5XD 6,3 IK VHM

SD 45 5XD 6,4 IK VHM

SD 45 5XD 6,5 IK VHM

SD 45 5XD 6,6 IK VHM

SD 45 5XD 6,7 IK VHM

SD 45 5XD 6,8 IK VHM

SD 45 5XD 6,9 IK VHM

SD 45 5XD 7 IK VHM

SD 45 5XD 7,1 IK VHM

SD 45 5XD 7,2 IK VHM

SD 45 5XD 7,3 IK VHM

SD 45 5XD 7,4 IK VHM

SD 45 5XD 7,5 IK VHM

SD 45 5XD 7,6 IK VHM

SD 45 5XD 7,7 IK VHM

SD 45 5XD 7,8 IK VHM

SD 45 5XD 7,9 IK VHM

SD 45 5XD 8 IK VHM

SD 45 5XD 8,1 IK VHM

SD 45 5XD 8,2 IK VHM

SD 45 5XD 8,3 IK VHM

SD 45 5XD 8,4 IK VHM

SD 45 5XD 8,5 IK VHM

SD 45 5XD 8,6 IK VHM

SD 45 5XD 8,7 IK VHM

SD 45 5XD 8,8 IK VHM

SD 45 5XD 8,9 IK VHM

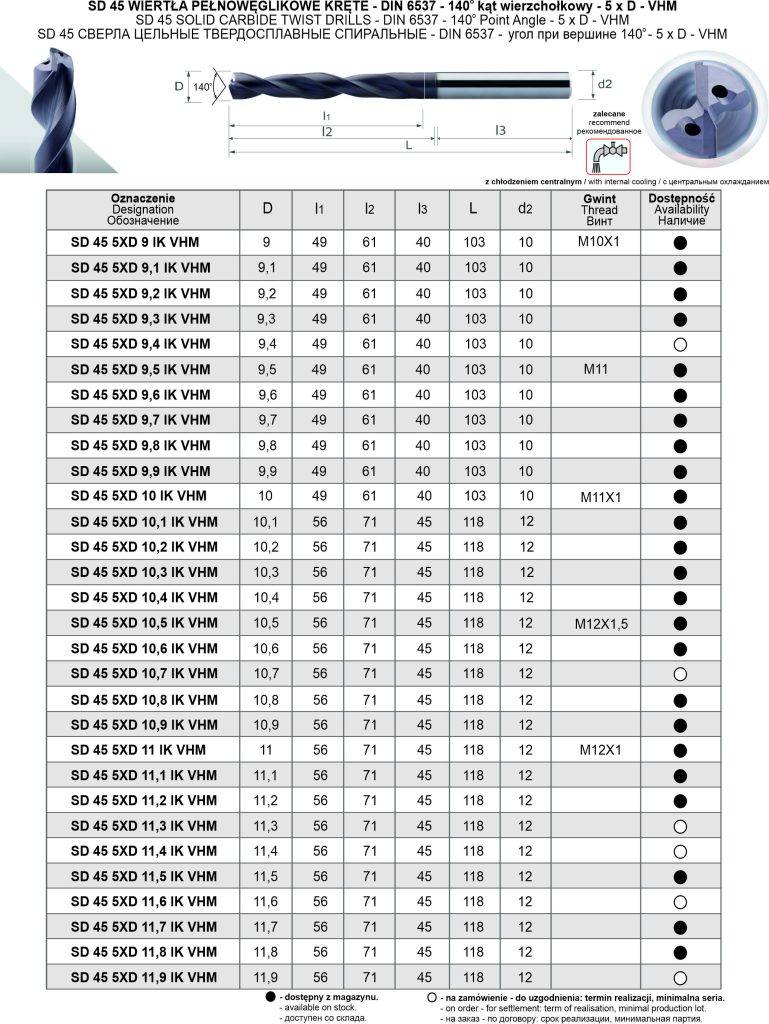

SD 45 5XD 9 IK VHM

SD 45 5XD 9,1 IK VHM

SD 45 5XD 9,2 IK VHM

SD 45 5XD 9,3 IK VHM

SD 45 5XD 9,4 IK VHM

SD 45 5XD 9,5 IK VHM

SD 45 5XD 9,6 IK VHM

SD 45 5XD 9,7 IK VHM

SD 45 5XD 9,8 IK VHM

SD 45 5XD 9,9 IK VHM

SD 45 5XD 10 IK VHM

SD 45 5XD 10,1 IK VHM

SD 45 5XD 10,2 IK VHM

SD 45 5XD 10,3 IK VHM

SD 45 5XD 10,4 IK VHM

SD 45 5XD 10,5 IK VHM

SD 45 5XD 10,6 IK VHM

SD 45 5XD 10,7 IK VHM

SD 45 5XD 10,8 IK VHM

SD 45 5XD 10,9 IK VHM

SD 45 5XD 11 IK VHM

SD 45 5XD 11,1 IK VHM

SD 45 5XD 11,2 IK VHM

SD 45 5XD 11,3 IK VHM

SD 45 5XD 11,4 IK VHM

SD 45 5XD 11,5 IK VHM

SD 45 5XD 11,6 IK VHM

SD 45 5XD 11,7 IK VHM

SD 45 5XD 11,8 IK VHM

SD 45 5XD 11,9 IK VHM

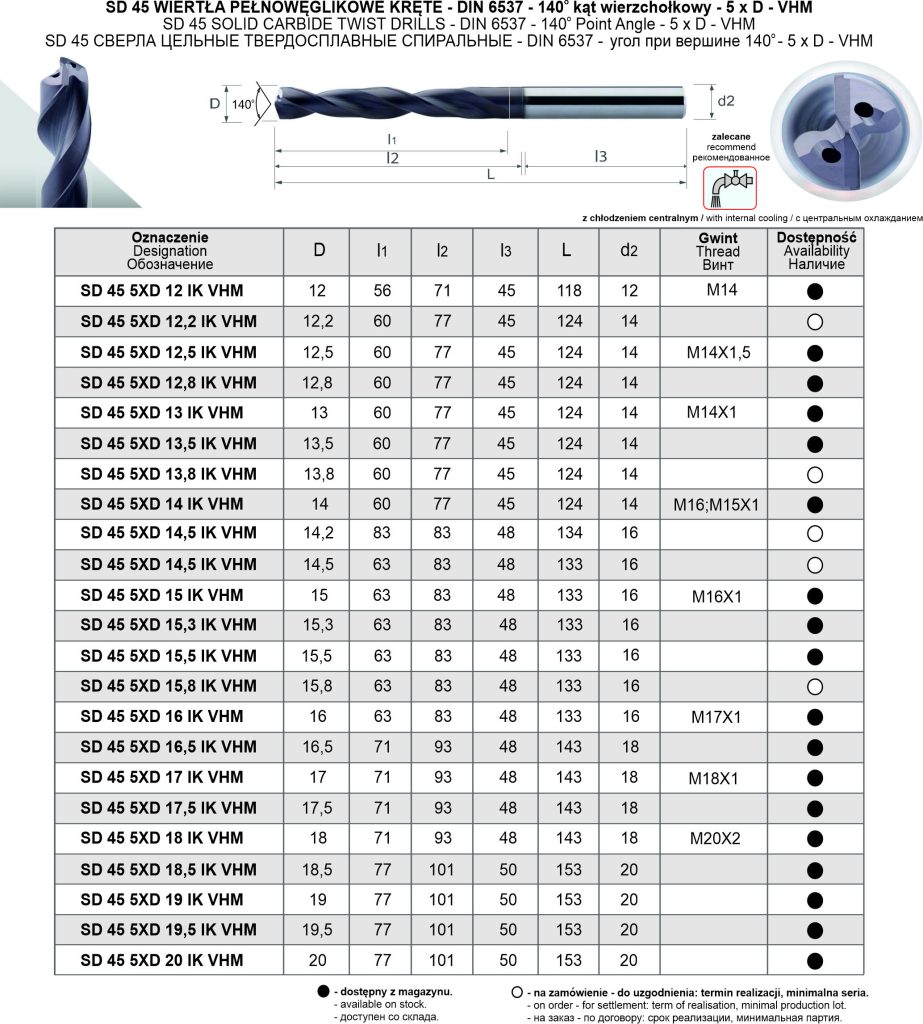

SD 45 5XD 12 IK VHM

SD 45 5XD 12,2 IK VHM

SD 45 5XD 12,5 IK VHM

SD 45 5XD 12,8 IK VHM

SD 45 5XD 13 IK VHM

SD 45 5XD 13,5 IK VHM

SD 45 5XD 13,8 IK VHM

SD 45 5XD 14 IK VHM

SD 45 5XD 14,5 IK VHM

SD 45 5XD 15 IK VHM

SD 45 5XD 15,3 IK VHM

SD 45 5XD 15,5 IK VHM

SD 45 5XD 15,8 IK VHM

SD 45 5XD 16 IK VHM

SD 45 5XD 16,5 IK VHM

SD 45 5XD 17 IK VHM

SD 45 5XD 17,5 IK VHM

SD 45 5XD 18 IK VHM

SD 45 5XD 18,5 IK VHM

SD 45 5XD 19 IK VHM

SD 45 5XD 19,5 IK VHM

SD 45 5XD 20 IK VHM

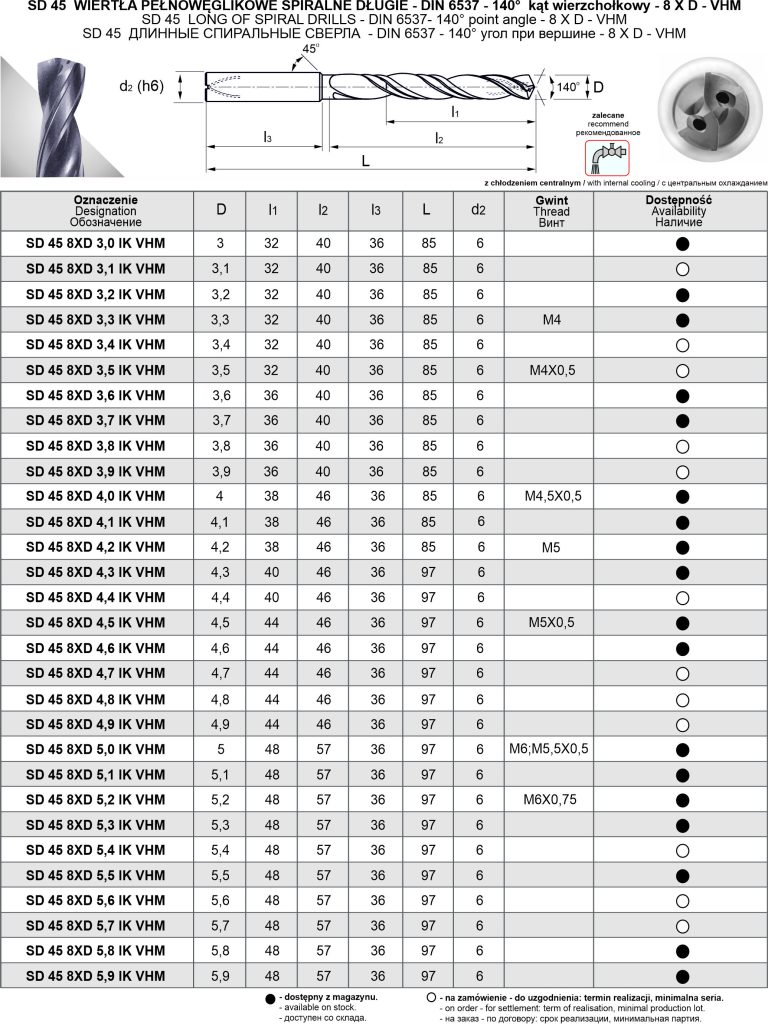

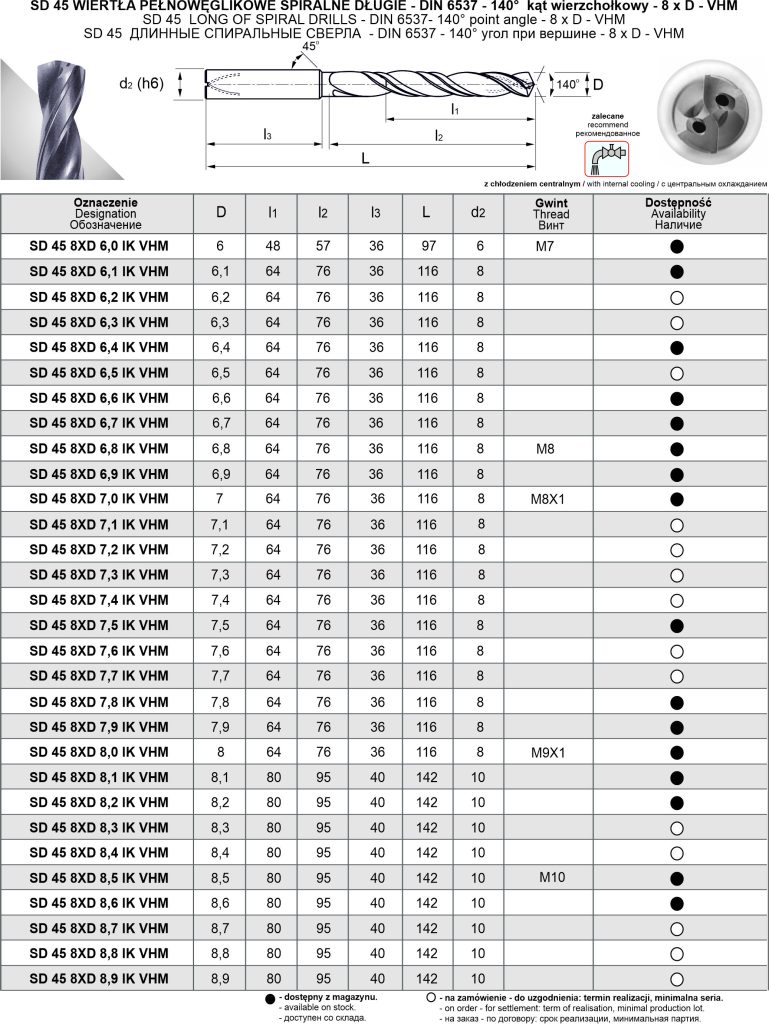

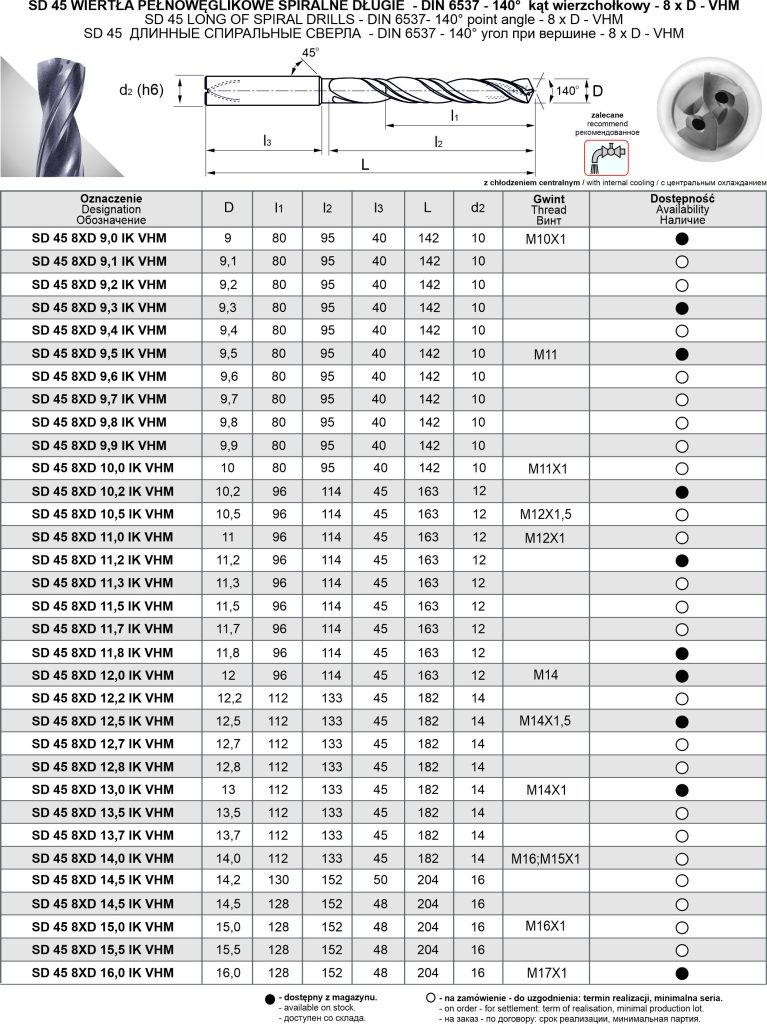

8XD WITH COOLANT.

SD 45 LONG OF SPIRAL DRILLS – DIN 6537- 140° point angle – 8 X D – VHM

SD 45 8XD 3,0 IK VHM

SD 45 8XD 3,1 IK VHM

SD 45 8XD 3,2 IK VHM

SD 45 8XD 3,3 IK VHM

SD 45 8XD 3,4 IK VHM

SD 45 8XD 3,5 IK VHM

SD 45 8XD 3,6 IK VHM

SD 45 8XD 3,7 IK VHM

SD 45 8XD 3,8 IK VHM

SD 45 8XD 3,9 IK VHM

SD 45 8XD 4,0 IK VHM

SD 45 8XD 4,1 IK VHM

SD 45 8XD 4,2 IK VHM

SD 45 8XD 4,3 IK VHM

SD 45 8XD 4,4 IK VHM

SD 45 8XD 4,5 IK VHM

SD 45 8XD 4,6 IK VHM

SD 45 8XD 4,7 IK VHM

SD 45 8XD 4,8 IK VHM

SD 45 8XD 4,9 IK VHM

SD 45 8XD 5,0 IK VHM

SD 45 8XD 5,1 IK VHM

SD 45 8XD 5,2 IK VHM

SD 45 8XD 5,3 IK VHM

SD 45 8XD 5,4 IK VHM

SD 45 8XD 5,5 IK VHM

SD 45 8XD 5,6 IK VHM

SD 45 8XD 5,7 IK VHM

SD 45 8XD 5,8 IK VHM

SD 45 8XD 5,9 IK VHM

SD 45 8XD 6,0 IK VHM

SD 45 8XD 6,1 IK VHM

SD 45 8XD 6,2 IK VHM

SD 45 8XD 6,3 IK VHM

SD 45 8XD 6,4 IK VHM

SD 45 8XD 6,5 IK VHM

SD 45 8XD 6,6 IK VHM

SD 45 8XD 6,7 IK VHM

SD 45 8XD 6,8 IK VHM

SD 45 8XD 6,9 IK VHM

SD 45 8XD 7,0 IK VHM

SD 45 8XD 7,1 IK VHM

SD 45 8XD 7,2 IK VHM

SD 45 8XD 7,3 IK VHM

SD 45 8XD 7,4 IK VHM

SD 45 8XD 7,5 IK VHM

SD 45 8XD 7,6 IK VHM

SD 45 8XD 7,7 IK VHM

SD 45 8XD 7,8 IK VHM

SD 45 8XD 7,9 IK VHM

SD 45 8XD 8,0 IK VHM

SD 45 8XD 8,1 IK VHM

SD 45 8XD 8,2 IK VHM

SD 45 8XD 8,3 IK VHM

SD 45 8XD 8,4 IK VHM

SD 45 8XD 8,5 IK VHM

SD 45 8XD 8,6 IK VHM

SD 45 8XD 8,7 IK VHM

SD 45 8XD 8,8 IK VHM

SD 45 8XD 8,9 IK VHM

SD 45 8XD 9,0 IK VHM

SD 45 8XD 9,1 IK VHM

SD 45 8XD 9,2 IK VHM

SD 45 8XD 9,3 IK VHM

SD 45 8XD 9,4 IK VHM

SD 45 8XD 9,5 IK VHM

SD 45 8XD 9,6 IK VHM

SD 45 8XD 9,7 IK VHM

SD 45 8XD 9,8 IK VHM

SD 45 8XD 9,9 IK VHM

SD 45 8XD 10,0 IK VHM

SD 45 8XD 10,2 IK VHM

SD 45 8XD 10,5 IK VHM

SD 45 8XD 11,0 IK VHM

SD 45 8XD 11,2 IK VHM

SD 45 8XD 11,3 IK VHM

SD 45 8XD 11,5 IK VHM

SD 45 8XD 11,7 IK VHM

SD 45 8XD 11,8 IK VHM

SD 45 8XD 12,0 IK VHM

SD 45 8XD 12,2 IK VHM

SD 45 8XD 12,5 IK VHM

SD 45 8XD 12,7 IK VHM

SD 45 8XD 12,8 IK VHM

SD 45 8XD 13,0 IK VHM

SD 45 8XD 13,5 IK VHM

SD 45 8XD 13,7 IK VHM

SD 45 8XD 14,0 IK VHM

SD 45 8XD 14,5 IK VHM

SD 45 8XD 15,0 IK VHM

SD 45 8XD 15,5 IK VHM

SD 45 8XD 16,0 IK VHM

see the PAFANA on-line catalog: http://pafana.elkat.eu/#0

see the assortment of the PAFANA catalog edition 07/2020: https://pafana.pl/en/products/sd-45-solid-carbide-twist-drills-smart-drills-pafana-din6537-3xd-5xd-8xd-pafana-long-of-spiral-drills-pafana-sd-45-8-x-d/

see PAFANA news: https://pafana.pl/en/products/new/

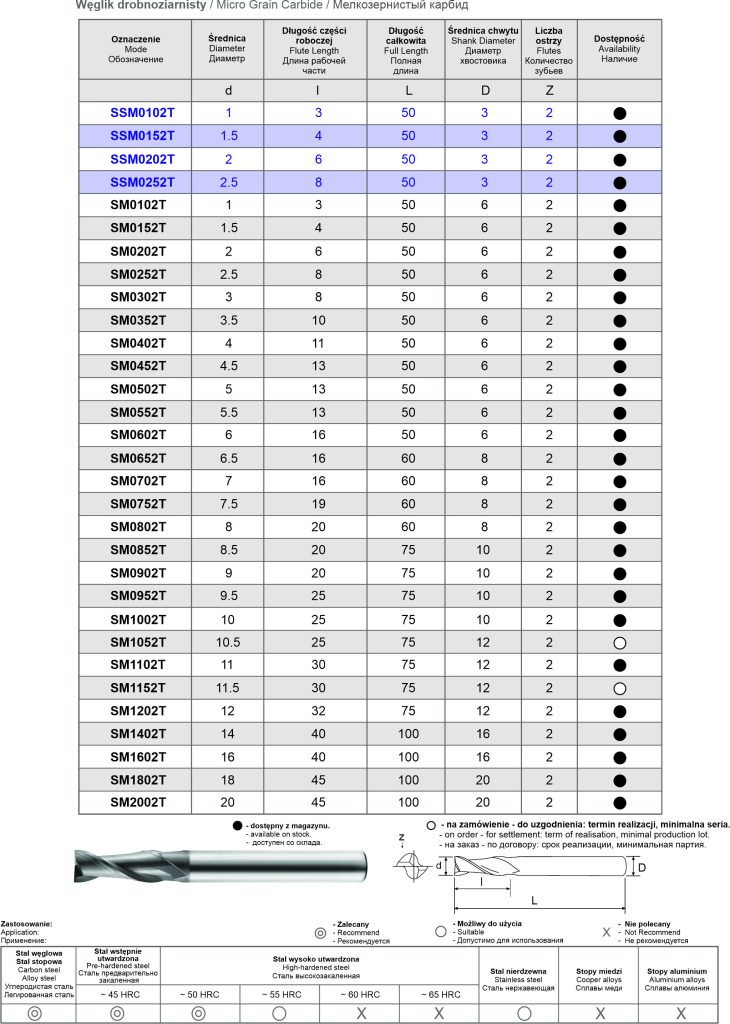

CARBIDE END MILLS „SMart Line” PAFANA.

ASSORTMENT:

OFFER PFN PAFANA S.A. INCLUDES:

SQUARE SERIES – 2 FLUTES END MILLS.

APPLICATION:

RECOMMEND – CARBON STEEL, ALLOY STEEL, PRE-HARDENED STEL, HIGHT-HARDENED STEEL TO 50 HRC.

SUITABLE – HIGHT-HARDENED STEEL TO 55 HRC, STAINLESS STEEL.

NOT RECOMMEND – HIGHT-HARDENED STEEL FROM 60 HRC TO 65 HRC, COOPER ALLOYS, ALUMINIUM ALLOYS.

SSM0102T

SSM0152T

SSM0202T

SSM0252T

SM0102T

SM0152T

SM0202T

SM0252T

SM0302T

SM0352T

SM0402T

SM0452T

SM0502T

SM0552T

SM0602T

SM0652T

SM0702T

SM0752T

SM0802T

SM0852T

SM0902T

SM0952T

SM1002T

SM1052T

SM1102T

SM1152T

SM1202T

SM1402T

SM1602T

SM1802T

SM2002T

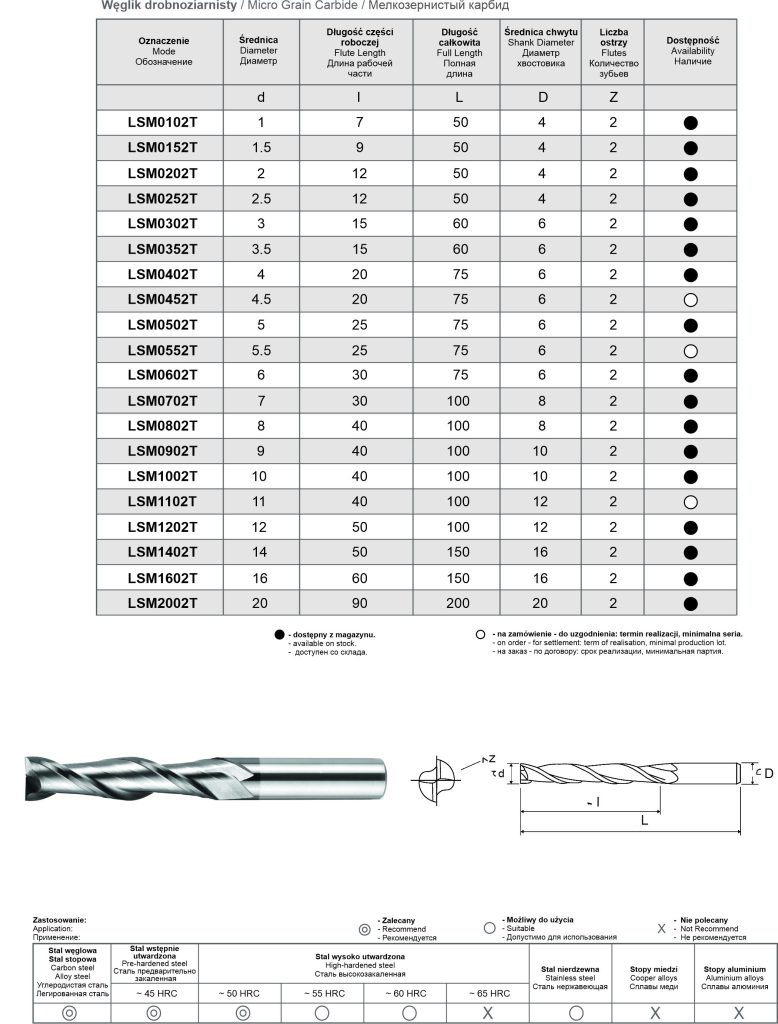

SQUARE SERIES – LONG FLUTE – 2 FLUTES END MILLS.

APPLICATION:

RECOMMEND – CARBON STEEL, ALLOY STEEL, PRE-HARDENED STEL, HIGHT-HARDENED STEEL TO 50 HRC.

SUITABLE – HIGHT-HARDENED STEEL TO 55 HRC, STAINLESS STEEL.

NOT RECOMMEND – HIGHT-HARDENED STEEL FROM 60 HRC TO 65 HRC, COOPER ALLOYS, ALUMINIUM ALLOYS.

LSM0102T

LSM0152T

LSM0202T

LSM0252T

LSM0302T

LSM0352T

LSM0402T

LSM0452T

LSM0502T

LSM0552T

LSM0602T

LSM0702T

LSM0802T

LSM0902T

LSM1002T

LSM1102T

LSM1202T

LSM1402T

LSM1602T

LSM2002T

BALL NOSE – 2 FLUTES END MILLS.

APPLICATION:

RECOMMEND – CARBON STEEL, ALLOY STEEL, PRE-HARDENED STEL, HIGHT-HARDENED STEEL TO 50 HRC.

SUITABLE – HIGHT-HARDENED STEEL TO 55 HRC, STAINLESS STEEL.

NOT RECOMMEND – HIGHT-HARDENED STEEL FROM 60 HRC TO 65 HRC, COOPER ALLOYS, ALUMINIUM ALLOYS.

SBSM0102T

SBSM0152T

SBSM0202T

SBSM0252T

BSM0102T

BSM0152T

BSM0202T

BSM0252T

BSM0302T

BSM0352T

BSM0402T

BSM0452T

BSM0502T

BSM0552T

BSM0602T

BSM0702T

BSM0802T

BSM0902T

BSM1002T

BSM1102T

BSM1202T

BSM1402T

BSM1602T

BSM1802T

BSM2002T

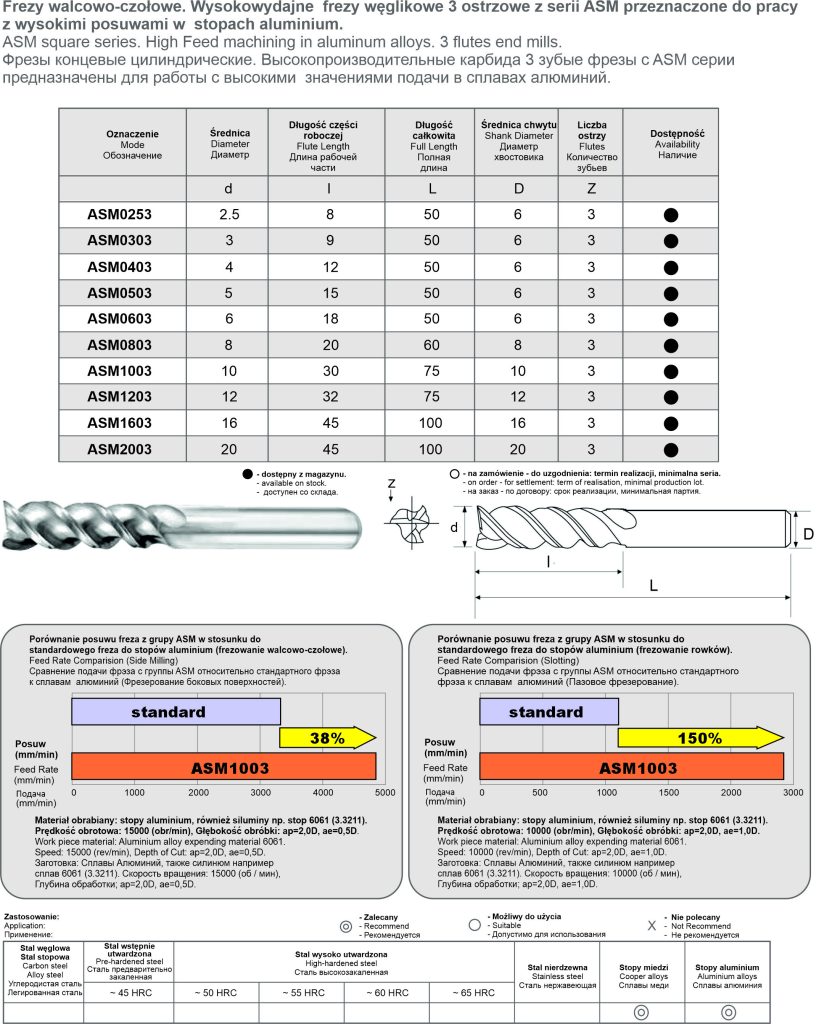

SQUARE SERIES – HIGH FEED – ALUMINIUM – 3 FLUTES END MILLS.

ASM SERIES. HIGH FEED MACHINING IN ALUMINIUM ALLOYS. 3 FLUTES CARBIDE END MILLS

APPLICATION:

– ALUMINIUM AND COPPER ALLOYS.

ASM0253

ASM0303

ASM0403

ASM0503

ASM0603

ASM0803

ASM1003

ASM1203

ASM1603

ASM2003

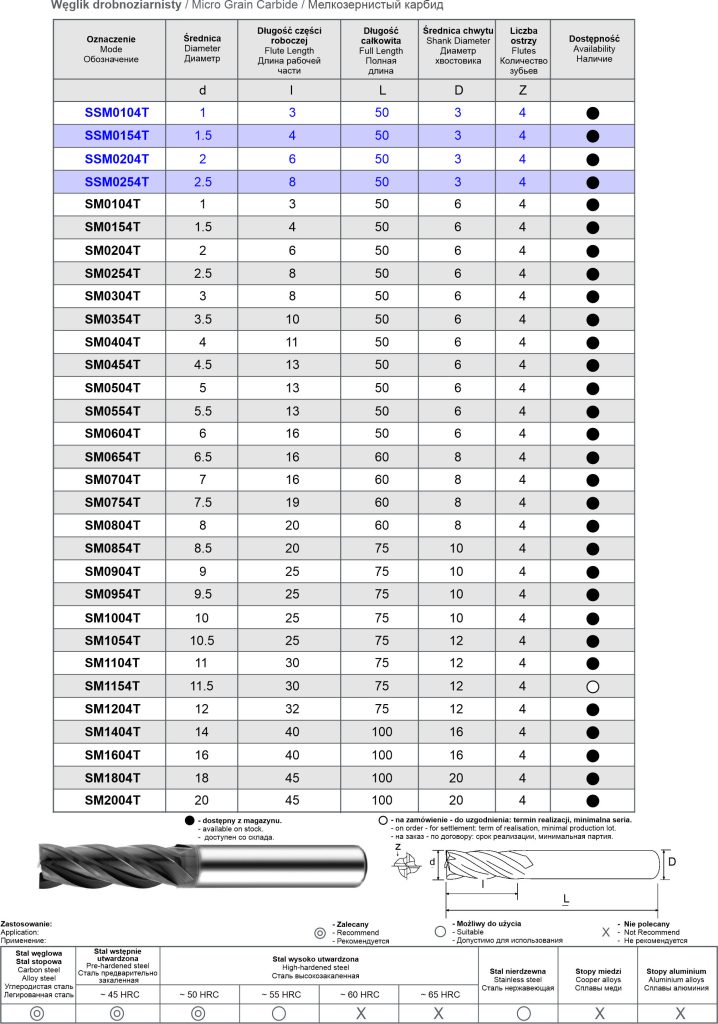

SQUARE SERIES – 4 FLUTES END MILLS.

APPLICATION:

RECOMMEND – CARBON STEEL, ALLOY STEEL, PRE-HARDENED STEL, HIGHT-HARDENED STEEL TO 50 HRC.

SUITABLE – HIGHT-HARDENED STEEL TO 55 HRC, STAINLESS STEEL.

NOT RECOMMEND – HIGHT-HARDENED STEEL FROM 60 HRC TO 65 HRC, COOPER ALLOYS, ALUMINIUM ALLOYS.

SSM0104T

SSM0154T

SSM0204T

SSM0254T

SM0104T

SM0154T

SM0204T

SM0254T

SM0304T

SM0354T

SM0404T

SM0454T

SM0504T

SM0554T

SM0604T

SM0654T

SM0704T

SM0754T

SM0804T

SM0854T

SM0904T

SM0954T

SM1004T

SM1054T

SM1104T

SM1154T

SM1204T

SM1404T

SM1604T

SM1804T

SM2004T

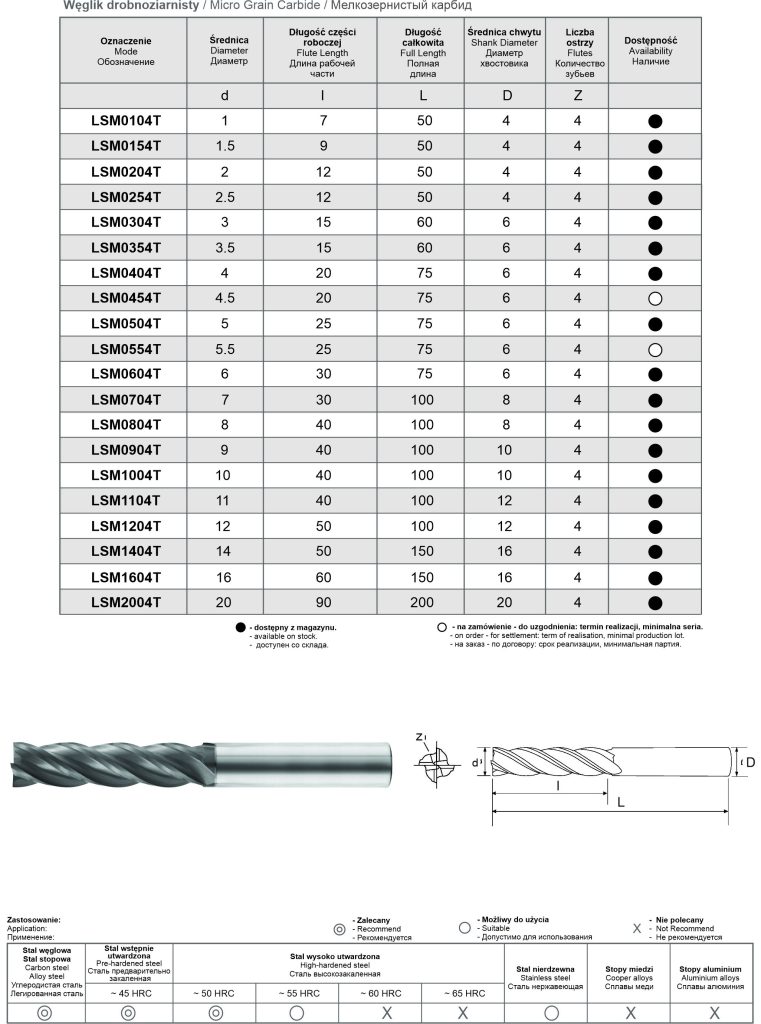

SQUARE SERIES – LONG FLUTE – 4 FLUTES END MILLS.

APPLICATION:

RECOMMEND – CARBON STEEL, ALLOY STEEL, PRE-HARDENED STEL, HIGHT-HARDENED STEEL TO 50 HRC.

SUITABLE – HIGHT-HARDENED STEEL TO 55 HRC, STAINLESS STEEL.

NOT RECOMMEND – HIGHT-HARDENED STEEL FROM 60 HRC TO 65 HRC, COOPER ALLOYS, ALUMINIUM ALLOYS.

LSM0104T

LSM0154T

LSM0204T

LSM0254T

LSM0304T

LSM0354T

LSM0404T

LSM0454T

LSM0504T

LSM0554T

LSM0604T

LSM0704T

LSM0804T

LSM0904T

LSM1004T

LSM1104T

LSM1204T

LSM1404T

LSM1604T

LSM2004T

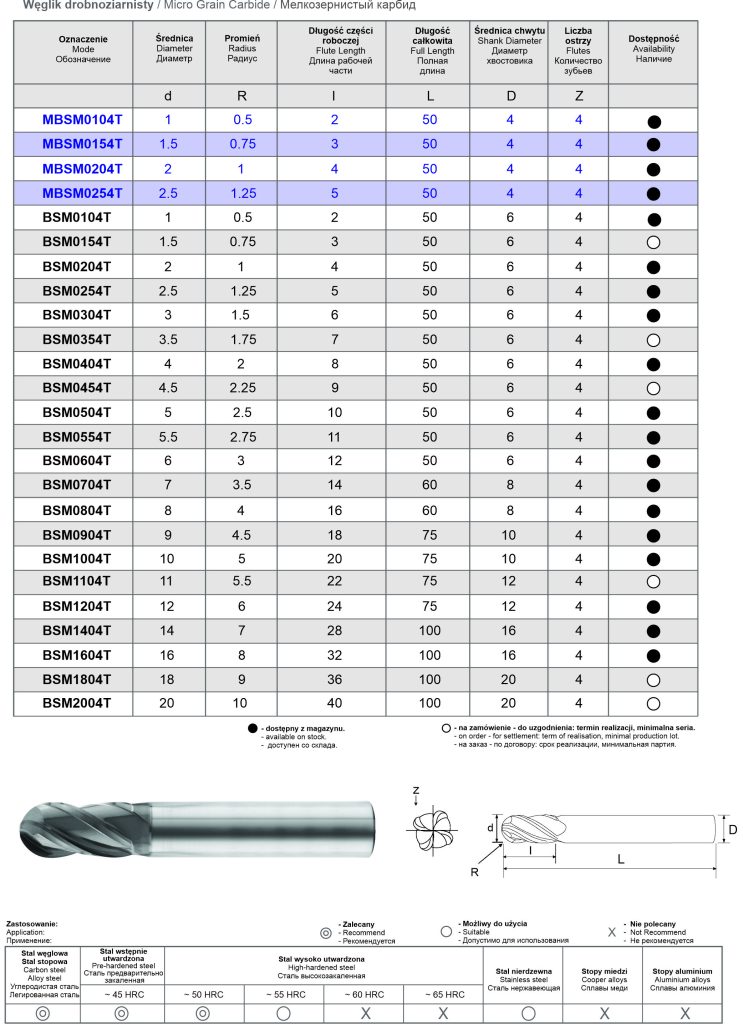

BALL NOSE – 4 FLUTES END MILLS.

APPLICATION:

RECOMMEND – CARBON STEEL, ALLOY STEEL, PRE-HARDENED STEL, HIGHT-HARDENED STEEL TO 50 HRC.

SUITABLE – HIGHT-HARDENED STEEL TO 55 HRC, STAINLESS STEEL.

NOT RECOMMEND – HIGHT-HARDENED STEEL FROM 60 HRC TO 65 HRC, COOPER ALLOYS, ALUMINIUM ALLOYS.

MBSM0104T

MBSM0154T

MBSM0204T

MBSM0254T

BSM0104T

BSM0154T

BSM0204T

BSM0254T

BSM0304T

BSM0354T

BSM0454T

BSM0504T

BSM0554T

BSM0604T

BSM0704T

BSM0804T

BSM0904T

BSM1004T

BSM1104T

BSM1204T

BSM1404T

BSM1604T

BSM1804T

BSM2004T

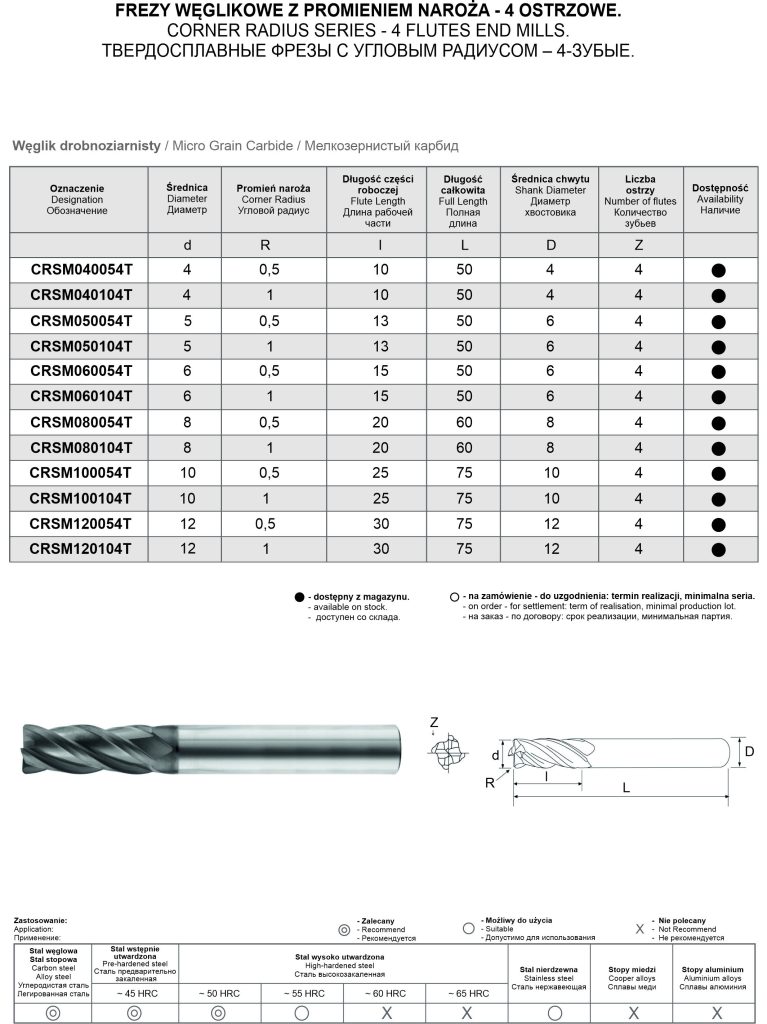

CORNER RADIUS SERIES – 4 FLUTES END MILLS.

APPLICATION:

RECOMMEND – CARBON STEEL, ALLOY STEEL, PRE-HARDENED STEL, HIGHT-HARDENED STEEL TO 50 HRC.

SUITABLE – HIGHT-HARDENED STEEL TO 55 HRC, STAINLESS STEEL.

NOT RECOMMEND – HIGHT-HARDENED STEEL FROM 60 HRC TO 65 HRC, COOPER ALLOYS, ALUMINIUM ALLOYS.

CRSM040054T

CRSM040104T

CRSM050054T

CRSM050104T

CRSM060054T

CRSM060104T

CRSM080054T

CRSM080104T

CRSM100054T

CRSM100104T

CRSM120054T

CRSM120104T

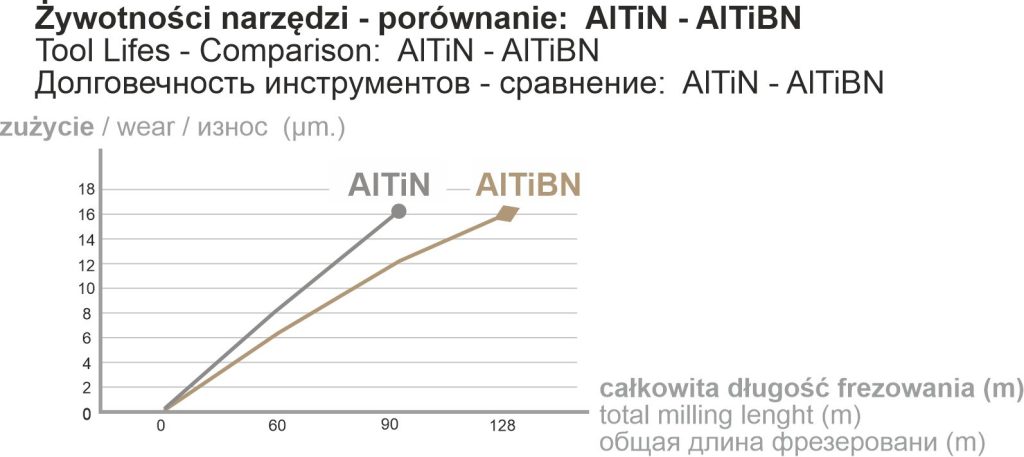

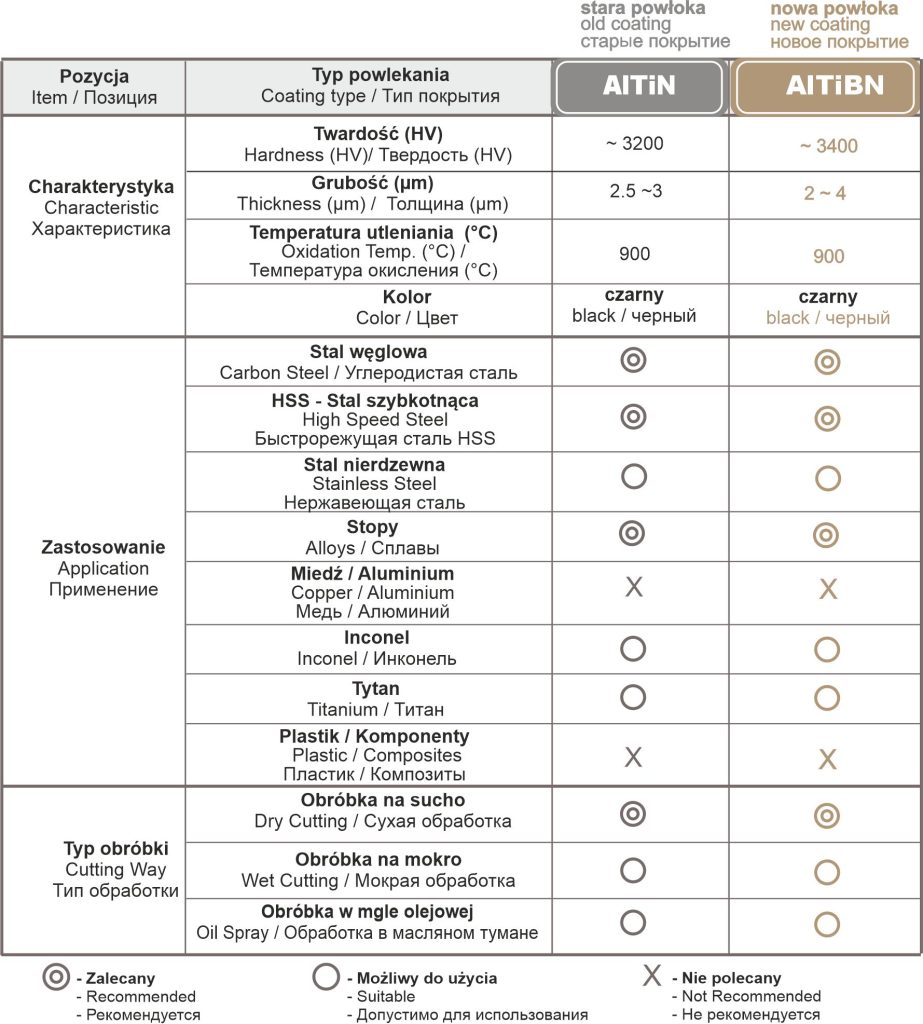

END MILLS WITH THE NEW ALTIBN COATING OF 2 TO 4 µM COATINGS WITH IMPROVED TECHNICAL PARAMETERS. HV HARDNESS UP TO 3400.

APPLICATION MAINLY FOR CARBON STEEL, HSS – HIGH-SPEED STEEL, IRON ALLOYS AND ALSO POSSIBLE FOR USE ON STAINLESS STEEL, INCONEL, AND TITANIUM. DRY MACHINING.

see the PAFANA on-line catalog: http://pafana.elkat.eu/#0

see the assortment of the PAFANA catalog edition 07/2020: https://pafana.pl/en/products/carbide-end-mills-smart-line-pafana-square-series-2-flutes-end-mills-square-series-long-flute-2-flutes-end-mills-ball-nose-2-flutes-end-mills-square-series-high-feed-aluminium-3-flutes-square-series/

see PAFANA news: https://pafana.pl/en/products/new/

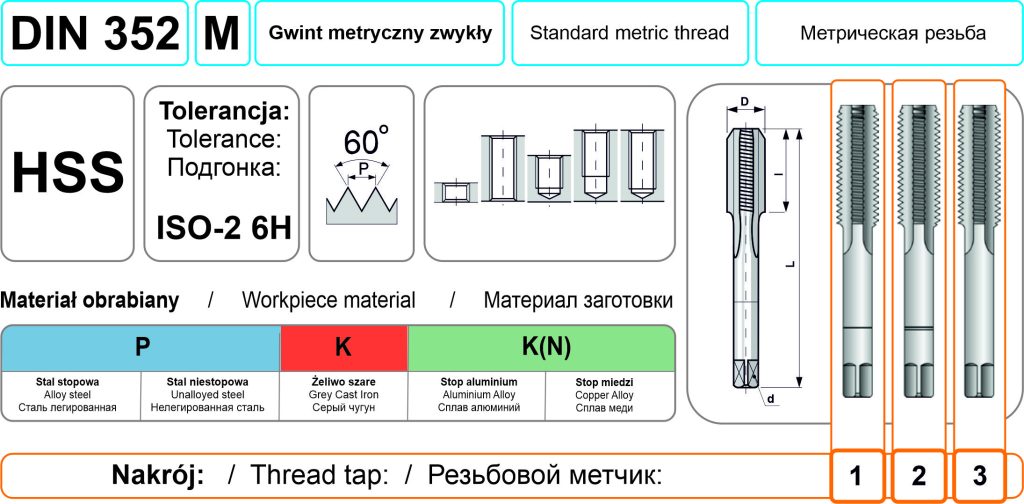

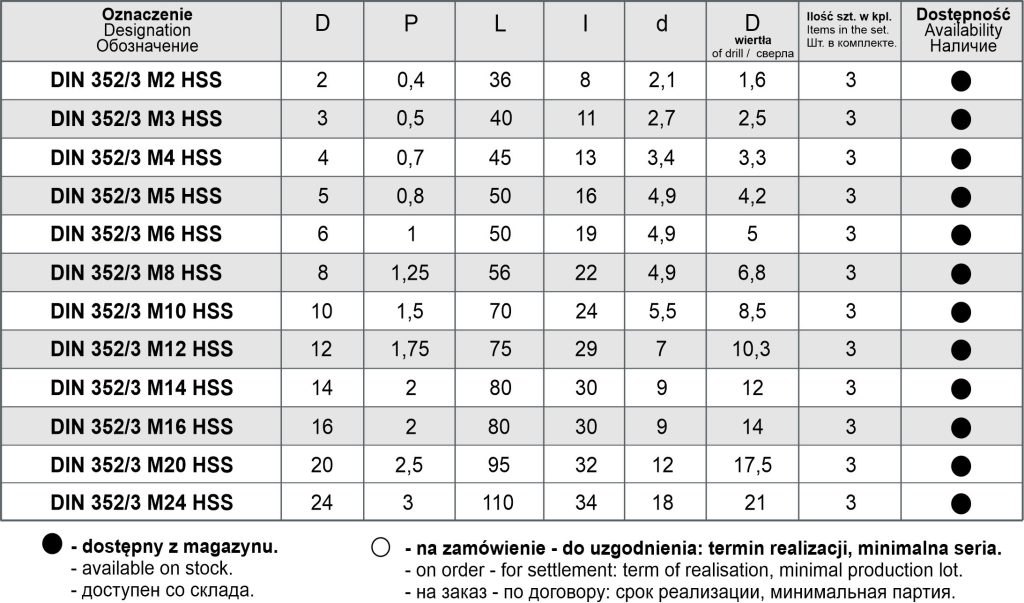

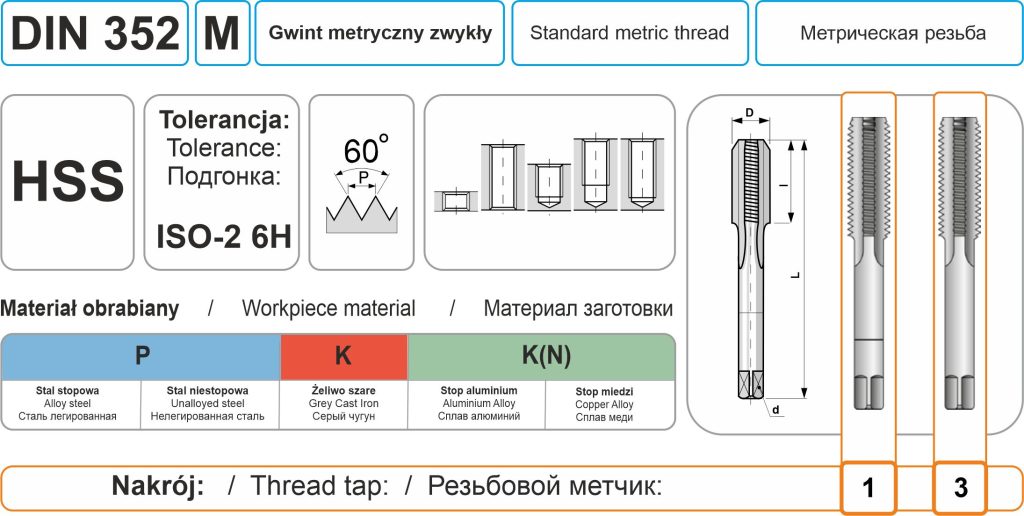

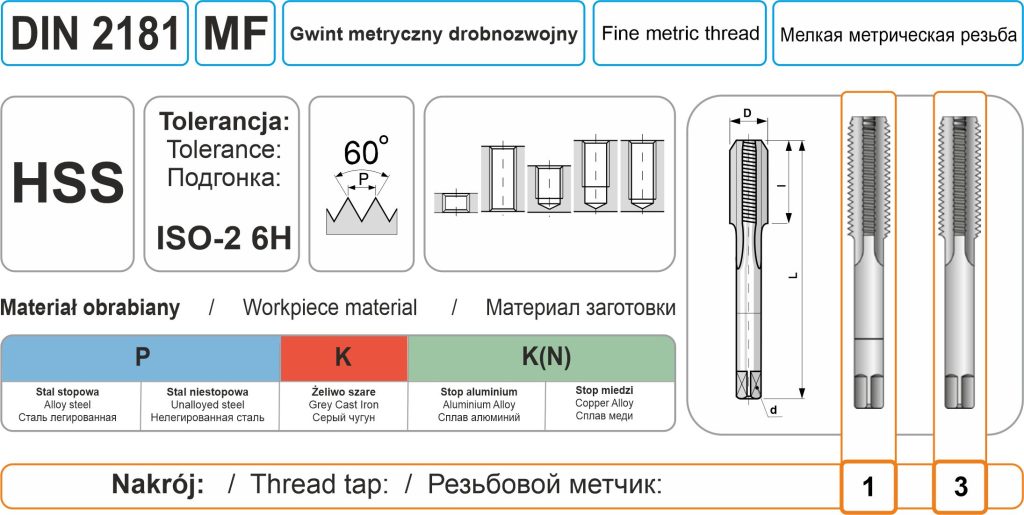

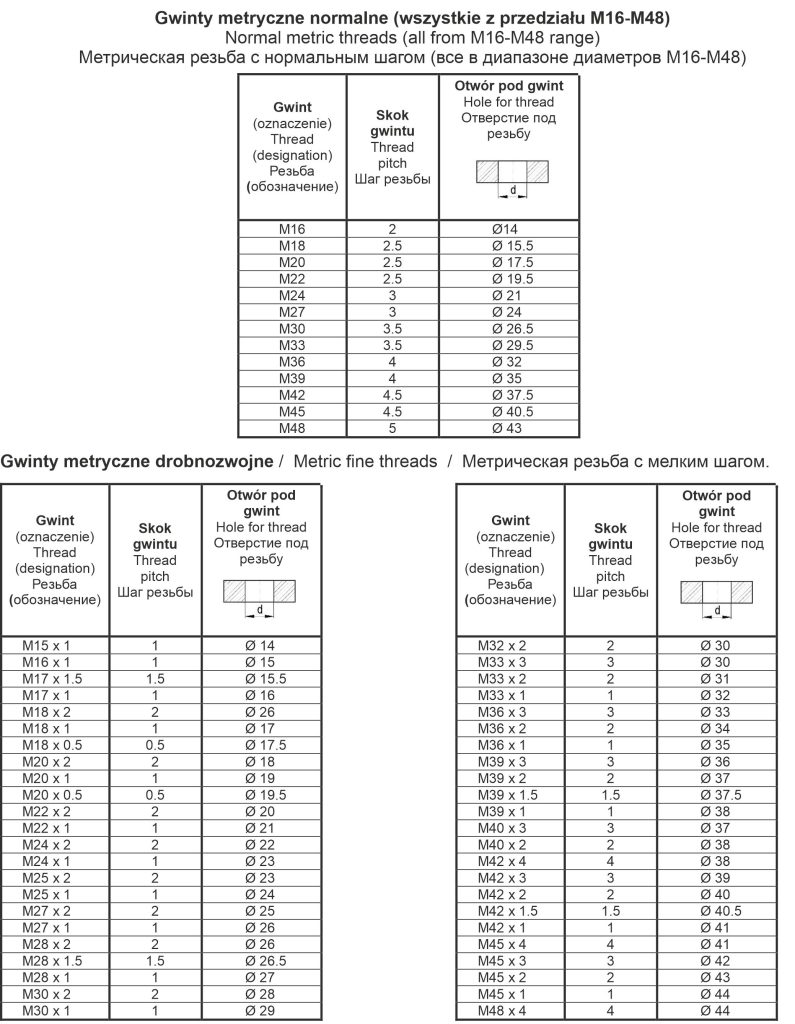

NEW PAFANA 02/2023 – HAND TAPS PAFANA – SMART TAPS PAFANA.

HAND TAPS FOR METRIC AND INCH THREADS PAFANA 2023.

ASSORTMENT:

PFN PAFANA S.A. OFFERS HAND TAPS IN THE FOLLOWING CONFIGURATIONS:

HAND TAPS FOR METRIC THREADS (SET OF 3 PCS.)

DIN 352/3 M HSS. STANDARD METRIC THREAD.TOLERANCE ISO-2 6H. WORKPIECE MATERIAL: P, K, K(N).

DIN 352/3 M2 HSS

DIN 352/3 M3 HSS

DIN 352/3 M4 HSS

DIN 352/3 M5 HSS

DIN 352/3 M6 HSS

DIN 352/3 M8 HSS

DIN 352/3 M10 HSS

DIN 352/3 M12 HSS

DIN 352/3 M14 HSS

DIN 352/3 M16 HSS

DIN 352/3 M20 HSS

DIN 352/3 M24 HSS

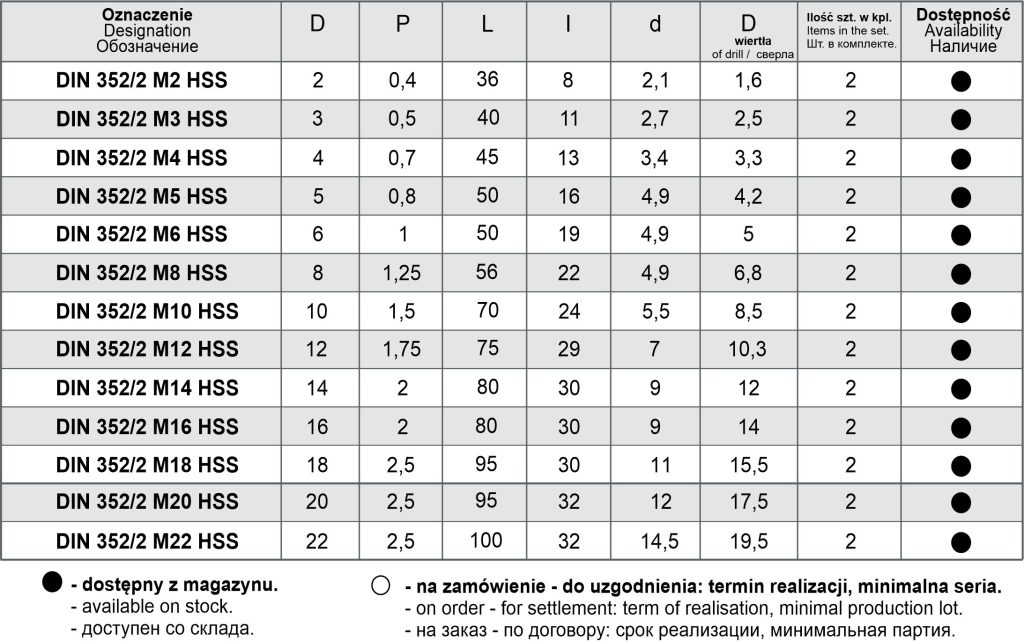

HAND TAPS FOR METRIC THREADS (SET OF 2 PCS.)

DIN 352/2 M HSS. STANDARD METRIC THREAD.TOLERANCE ISO-2 6H. WORKPIECE MATERIAL: P, K, K(N).

DIN 352/2 M2 HSS

DIN 352/2 M3 HSS

DIN 352/2 M4 HSS

DIN 352/2 M5 HSS

DIN 352/2 M6 HSS

DIN 352/2 M8 HSS

DIN 352/2 M10 HSS

DIN 352/2 M12 HSS

DIN 352/2 M14 HSS

DIN 352/2 M16 HSS

DIN 352/2 M 18 HSS

DIN 352/2 M 20 HSS

DIN 352/2 M 22 HSS

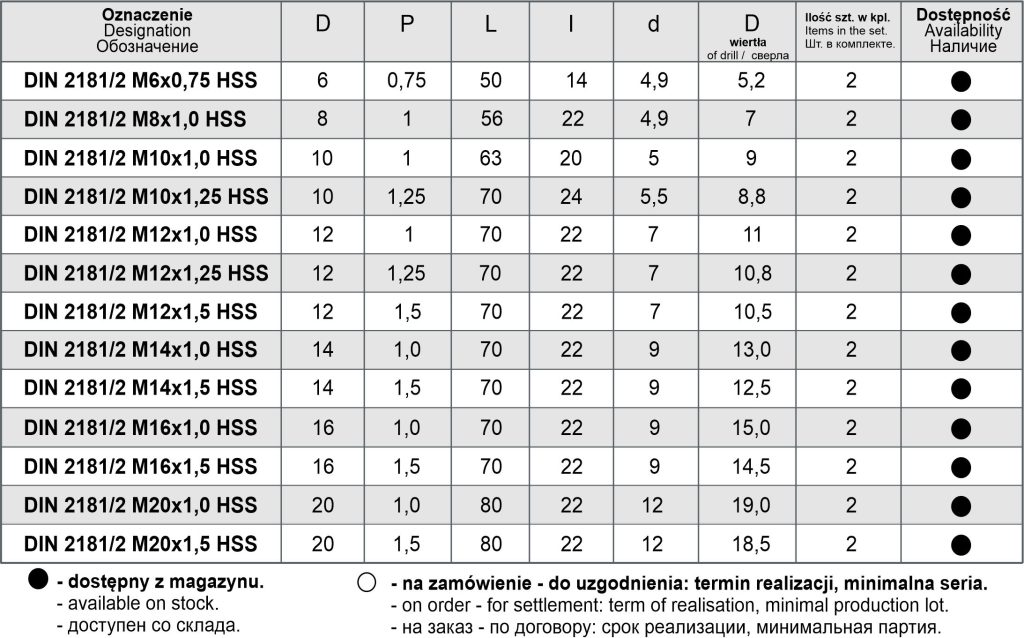

HAND TAPS FOR METRIC FINE THREADS (SET OF 2 PCS.)

DIN 2181/2 MF HSS. FINE METRIC THREAD.TOLERANCE ISO-2 6H. WORKPIECE MATERIAL: P, K, K(N).

DIN 2181/2 M6x0,75 HSS

DIN 2181/2 M8x1,0 HSS

DIN 2181/2 M10x1,0 HSS

DIN 2181/2 M10x1,25 HSS

DIN 2181/2 M12x1,0 HSS

DIN 2181/2 M12x1,25 HSS

DIN 2181/2 M12x1,5 HSS

DIN 2181/2 M14x1,0 HSS

DIN 2181/2 M14x1,5 HSS

DIN 2181/2 M16x1,0 HSS

DIN 2181/2 M16x1,5 HSS

DIN 2181/2 M20x1,0 HSS

DIN 2181/2 M20x1,5 HSS

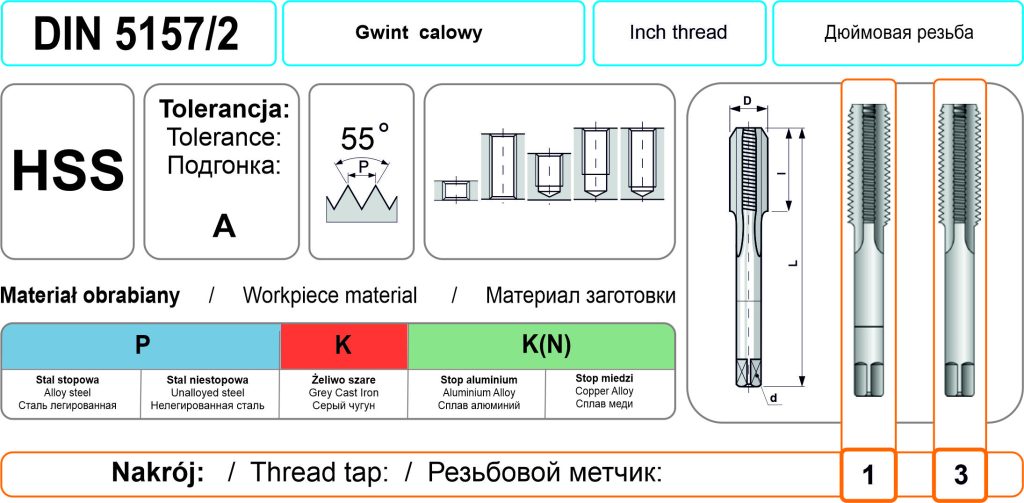

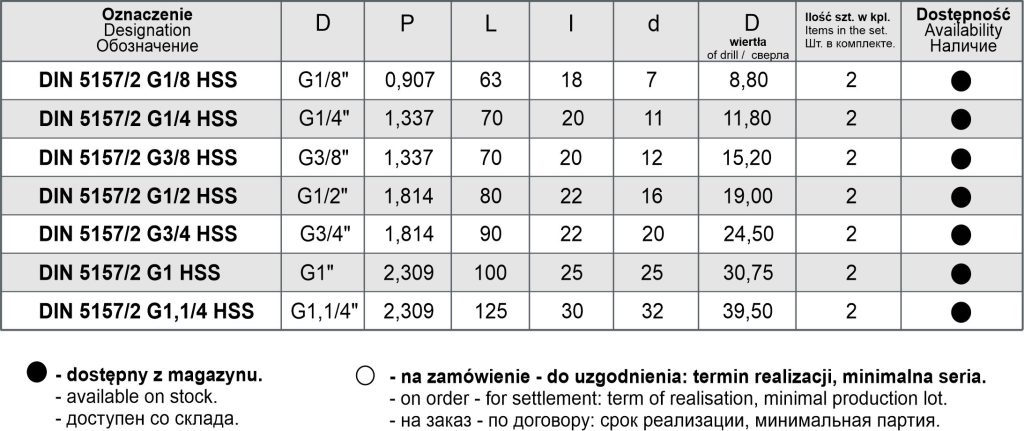

HAND TAPS FOR INCH THREADS (SET OF 2 PCS.)

DIN 5157/2 HSS. INCH THREAD.TOLERANCE A. WORKPIECE MATERIAL: P, K, K(N).

DIN 5157/2 G1/8 HSS

DIN 5157/2 G1/4 HSS

DIN 5157/2 G3/8 HSS

DIN 5157/2 G1/2 HSS

DIN 5157/2 G3/4 HSS

DIN 5157/2 G1 HSS

DIN 5157/2 G1,1/4 HSS

see the PAFANA on-line catalog: http://pafana.elkat.eu/#0

see the assortment of the PAFANA catalog edition 07/2020: https://pafana.pl/en/hand-taps-smart-taps-pafana/

see PAFANA news: https://pafana.pl/en/products/new/

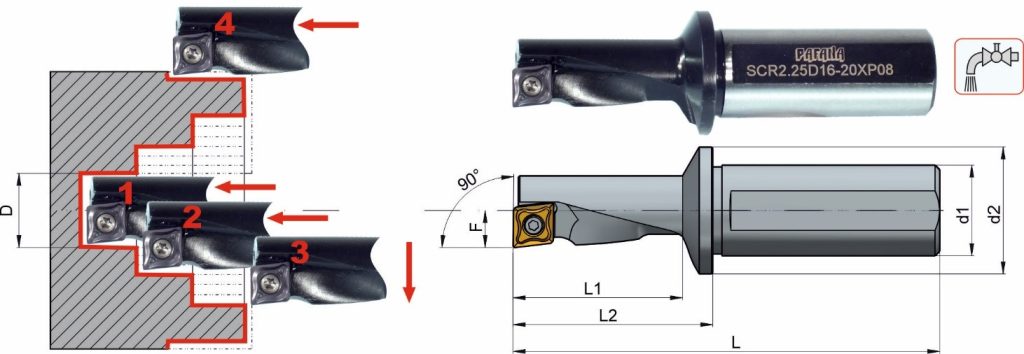

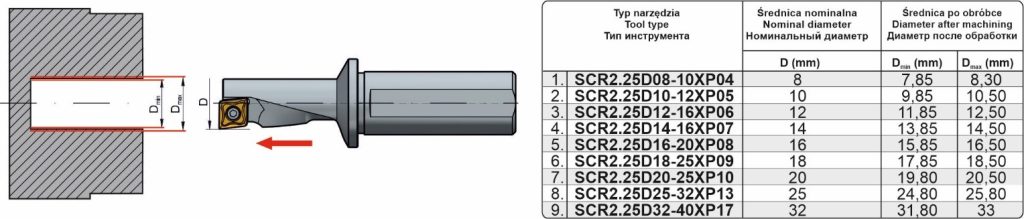

PAFANA “SMARTCUT” TOOLS.

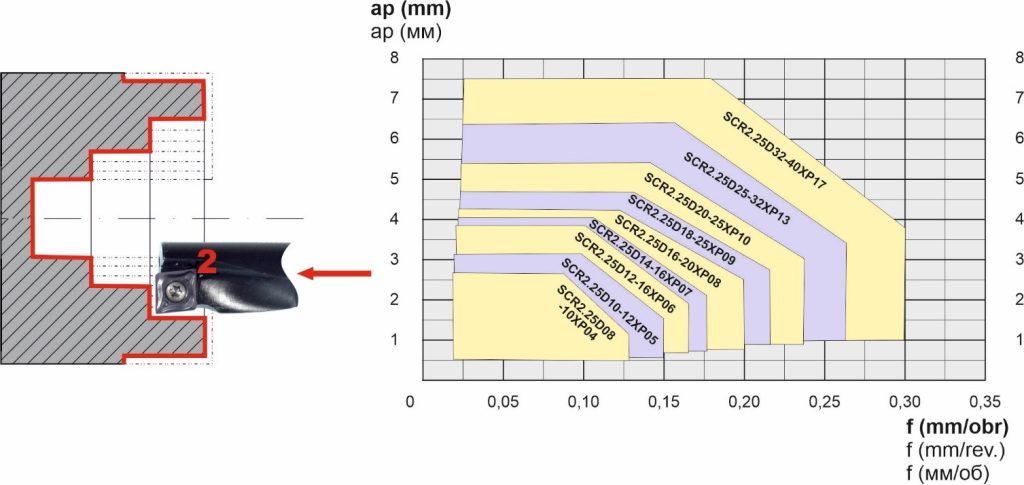

The universal single edge turning tool for drilling (1) in the solid material with the possibility of turning of internal profiles (2), facing operations (3), external turning applications (4).

Advantages for the Customer:

– the reduction of the tooling costs resulting from the use of a single tool for many technological treatments,

– the ability to perform a flat bottom of drilled hole,

– the reduction of the machine’s setup and programming time,

– a wide range of drilled holes in full material from Ø8 to Ø32 mm,

– directional cooling through the tool ensures the correct chip and heat removal from the machining zone.

The holes of the slightly smaller or larger diameter than the nominal diameter D can be performed (see table below). Off-axis drilling.

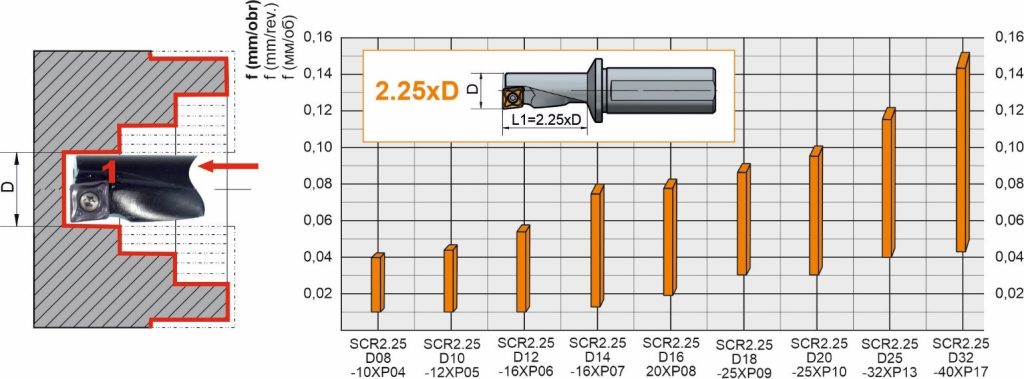

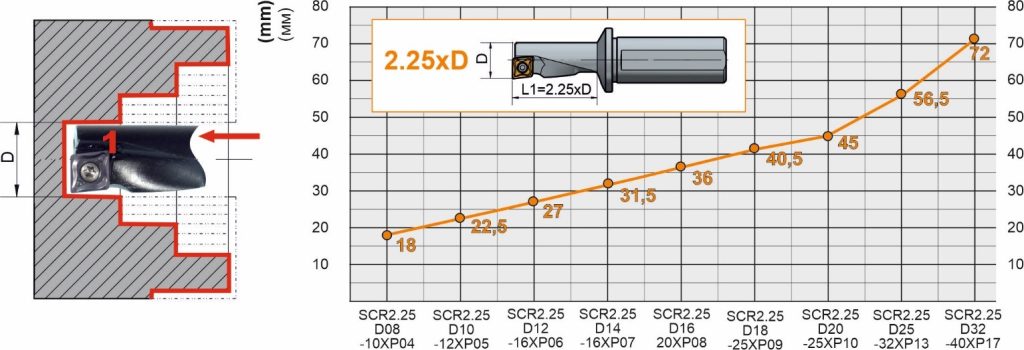

Drilling (1):

Drilling depth (1):

The plentiful coolant supply with a pressure of 5 – 10 bar and chip removal cycle should be used when drilling holes in the solid material.

Turning of internal profiles (2):

Depth of cut/feed rate – 2.25 x D.

ASSORTMENT PAFANA „SMART CUT” TOOLS:

SCR2.25D08-10XP04

PAFANA INSERTS: XP.T04…ER,

SCL2.25D08-10XP04

PAFANA INSERTS: XP.T04…EL,

SCR/L2.25D10-12XP05

PAFANA INSERTS: XP.T05…EN,

SCR/L2.25D12-16XP06

PAFANA INSERTS: XP.T06…EN,

SCR/L2.25D14-16XP07

PAFANA INSERTS: XP.T07…EN,

SCR/L2.25D16-20XP08

PAFANA INSERTS: XP.T08…EN,

SCR/L2.25D18-25XP09

PAFANA INSERTS: XP.T09…EN,

SCR/L2.25D20-25XP10

PAFANA INSERTS: XP.T10…EN,

SCR/L2.25D25-32XP13

PAFANA INSERTS: XP.T13…EN,

SCR/L2.25D32-40XP17

PAFANA INSERTS: XP.T17…EN.

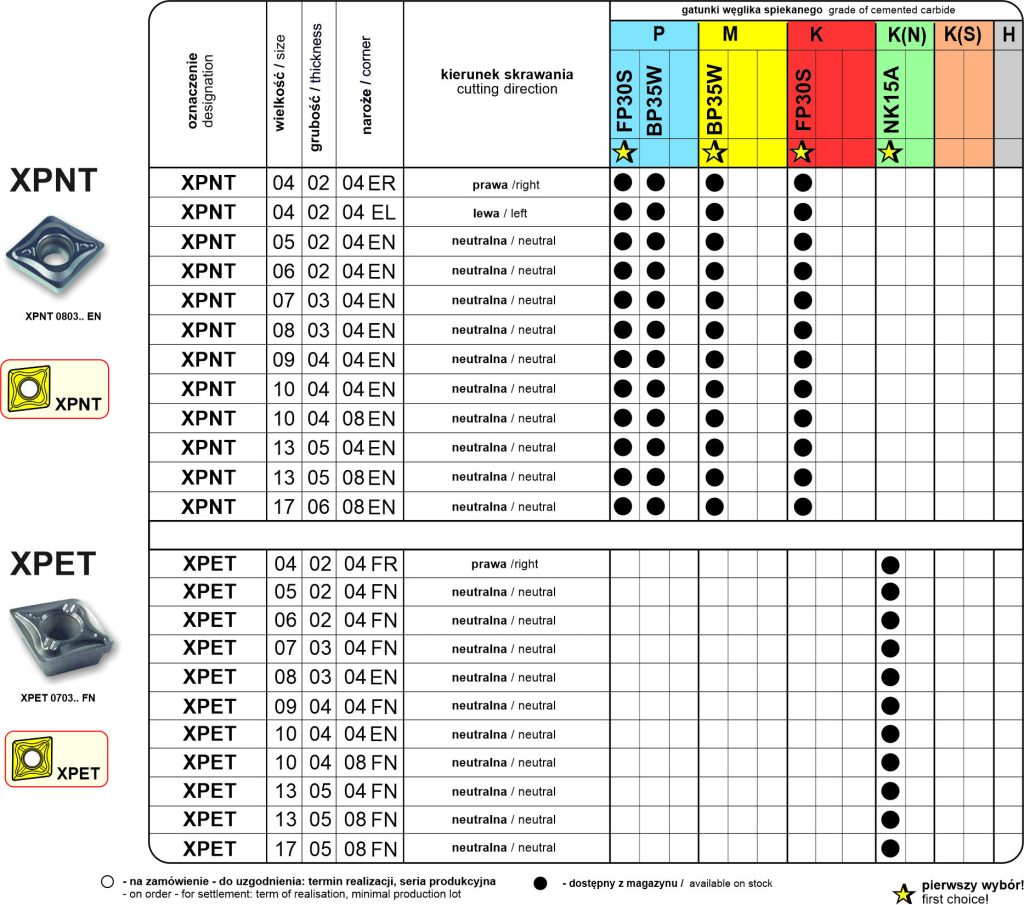

INSERTS XPNT, XPET FOR PAFANA SMARTCUT TOOLS SCR/L2.25D..-..XP..

XPNT:

XPNT 040204ER right FP30S (P), BP35W (P), BP35W(M), FP30S(K),

XPNT 040204EL left FP30S (P), BP35W (P), BP35W(M), FP30S(K),

XPNT 050204 EN neutral FP30S (P), BP35W (P), BP35W (M), FP30S (K),

XPNT 060204EN neutral FP30S (P), BP35W (P), BP35W (M), FP30S (K),

XPNT 070304EN neutral FP30S (P), BP35W (P), BP35W (M), FP30S (K),

XPNT 080304EN neutral FP30S (P), BP35W (P), BP35W (M), FP30S (K),

XPNT 090404EN neutral FP30S (P), BP35W (P), BP35W (M), FP30S (K),

XPNT 100404EN neutral FP30S (P), BP35W (P), BP35W (M), FP30S (K),

XPNT 100408EN neutral FP30S (P), BP35W (P), BP35W (M), FP30S (K),

XPNT 130504EN neutral FP30S (P), BP35W (P), BP35W (M), FP30S (K),

XPNT 130508EN neutral FP30S (P), BP35W (P), BP35W (M), FP30S (K),

XPNT 170608EN neutral FP30S (P), BP35W (P), BP35W (M), FP30S (K).

XPET:

XPET 040204FR right NK15A (K(N)),

XPET 050204FN neutral NK15A (K(N)),

XPET 060204FN neutral NK15A (K(N)),

XPET 070304FN neutral NK15A (K(N)),

XPET 080304FN neutral NK15A (K(N)),

XPET 090404FN neutral NK15A (K(N)),

XPET 100404FN neutral NK15A (K(N)),

XPET 100408FN neutral NK15A (K(N)),

XPET 130504FN neutral NK15A (K(N)),

XPET 130508FN neutral NK15A (K(N)),

XPET 170508FN neutral NK15A (K(N)).

A tool with an inconspicuous appearance works well even in unfavourable cutting conditions. Robust construction with a shank for use in modern CNC machines gives the option of an XPNT indexable insert (size 04-17) – for use in materials made of steel, corrosion-resistant steel, cast iron and XPET insert (size 04-17) – for use in materials from light alloys. Machining of various types of materials and the possibility of performing four machining operations proves the versatility of this tool – “PAFANA VERSATILE SINGLE-EDGE SMARTCUT TOOLS” IS NOT FICTION, IT’S REALITY.

see the PAFANA on-line catalog: http://pafana.elkat.eu/#0

see the assortment of the PAFANA catalog edition 07/2020: https://pafana.pl/en/products/toolholders-clamping-systems-for-inserts-system-s-boring-bars-with-sintered-carbide-shank-tool-holders-vdi-pta-20-28-boring-cartridges-toolholders-for-automatic-lathes-system-p-p-k-d-m-c-system-c-to/

see PAFANA news: https://pafana.pl/en/products/new/

INDEXABLE INSERT DRILLS / L = 3D, L = 4D, L = 5D / SD-..-SOLT WITH PAFANA INDEXABLE INSERTS SOLT…

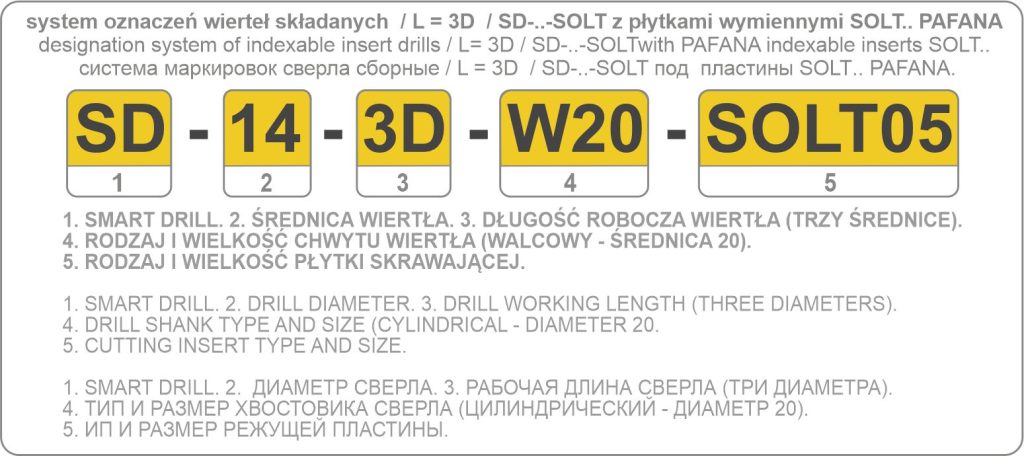

DESIGNATION SYSTEM OF PAFANA INDEXABLE INSERT DRILLS:

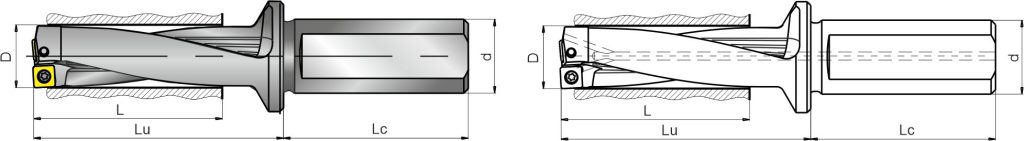

Indexable inserts drills produced by PFN PAFANA S.A. are modern cutting tools destined to cutting holes, turning and internal turning on machine tools having the large rigidity, and especially on modern CNC cutting machine tools.

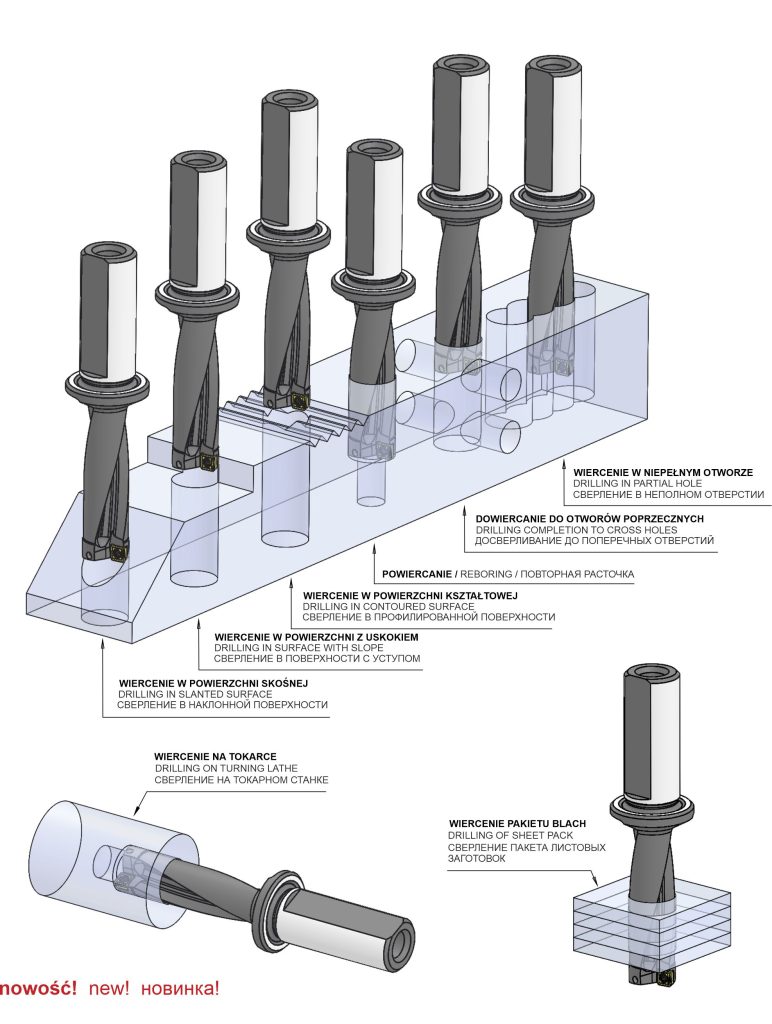

APPLICATIONS OF PAFANA INDEXABLE INSERT DRILLS:

Indexable insert drills SD-..-SOLT enable, except from basic type of hole drilling, to perform drilling completion to cross holes, reboring, drilling in contoured surface or drilling in slanted surface, drilling in partial hole and drilling of sheet pack.

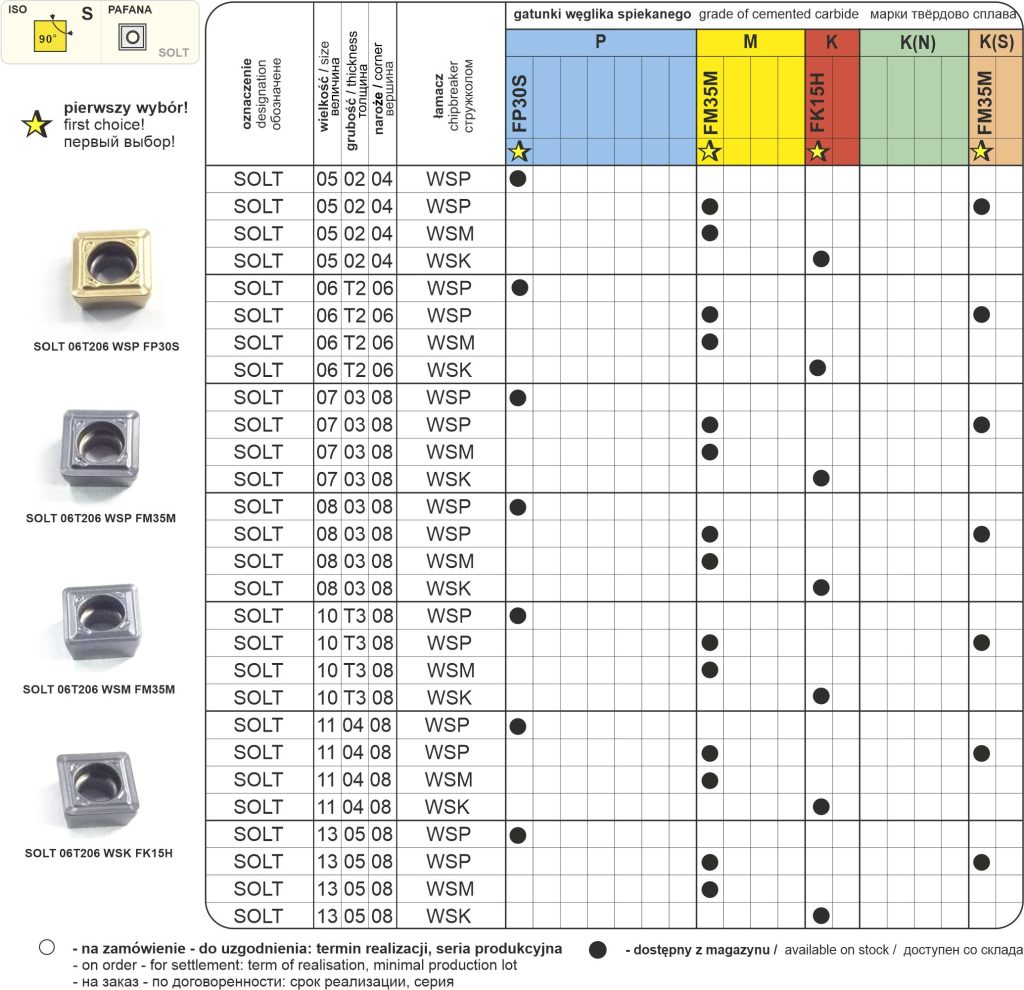

SOLT PAFANA INDEXABLE INSERTS:

In both seat drills SD-..-SOLT /internal and external/ we clamp the same indexable inserts -SOLT05…, SOLT06…, SOLT07…, SOLT08…, SOLT10…, SOLT11.., SOLT13….

Accessible indexable inserts to machining steel, stainless steels, cast iron, heat resistant alloys.

NEW ASSORTMENT OF PAFANA DRILLS 2021:

ASSORTMENT – 3D:

SD-14-3D-W20-SOLT05

SD-14,5-3D-W20-SOLT05

SD-15-3D-W20-SOLT05

SD-15,5-3D-W20-SOLT05

SD-16-3D-W20-SOLT05

SD-16,5-3D-W20-SOLT05

PAFANA INSERTS: SOLT 050204…

SD-17-3D-W20-SOLT06

SD-17,5-3D-W20-SOLT06

SD-18-3D-W25-SOLT06

SD-18,5-3D-W25-SOLT06

SD-19-3D-W25-SOLT06

SD-19,5-3D-W25-SOLT06

SD-19,5-3D-W25-SOLT06

PAFANA INSERTS: SOLT 06T206…

SD-20-3D-W25-SOLT07

SD-20,5-3D-W25-SOLT07

SD-21-3D-W25-SOLT07

SD-21,5-3D-W25-SOLT07

SD-22-3D-W25-SOLT07

SD-22,5-3D-W25-SOLT07

SD-23-3D-W25-SOLT07

SD-23,5-3D-W25-SOLT07

PAFANA INSERTS: SOLT 070308…

SD-24-3D-W32-SOLT08

SD-24,5-3D-W32-SOLT08

SD-25-3D-W32-SOLT08

SD-25,5-3D-W32-SOLT08

SD-26-3D-W32-SOLT08

SD-26,5-3D-W32-SOLT08

SD-27-3D-W32-SOLT08

SD-27,5-3D-W32-SOLT08

SD-28-3D-W32-SOLT08

SD-28,5-3D-W32-SOLT08

PAFANA INSERTS: SOLT 080308…

SD-29-3D-W32-SOLT10

SD-29,5-3D-W32-SOLT10

SD-30-3D-W32-SOLT10

SD-30,5-3D-W32-SOLT10

SD-31-3D-W40-SOLT10

SD-31,5-3D-W40-SOLT10

SD-32-3D-W40-SOLT10

SD-32,5-3D-W40-SOLT10

SD-33-3D-W40-SOLT10

SD-33,5-3D-W40-SOLT10

PAFANA INSERTS: SOLT 10T308…

SD-34-3D-W40-SOLT11

SD-34,5-3D-W40-SOLT11

SD-35-3D-W40-SOLT11

SD-35,5-3D-W40-SOLT11

SD-36-3D-W40-SOLT11

SD-36,5-3D-W40-SOLT11

SD-37-3D-W40-SOLT11

SD-37,5-3D-W40-SOLT11

SD-38-3D-W40-SOLT11

SD-38,5-3D-W40-SOLT11

PAFANA INSERTS: SOLT 110408…

SD-39-3D-W40-SOLT13

SD-39,5-3D-W40-SOLT13

SD-40-3D-W40-SOLT13

SD-40,5-3D-W40-SOLT13

SD-41-3D-W40-SOLT13

SD-41,5-3D-W40-SOLT13

SD-42-3D-W40-SOLT13

SD-42,5-3D-W40-SOLT13

SD-43-3D-W40-SOLT13

SD-43,5-3D-W40-SOLT13

SD-44-3D-W40-SOLT13

SD-44,5-3D-W40-SOLT13

PAFANA INSERTS: SOLT 130508…

ASSORTMENT – 4D:

SD-14-4D-W20-SOLT05

SD-14.5-4D-W20-SOLT05

SD-15-4D-W20-SOLT05

SD-15.5-4D-W20-SOLT05

SD-16-4D-W20-SOLT05

SD-16.5-4D-W20-SOLT05

PAFANA INSERTS: SOLT 050204…

SD-17-4D-W20-SOLT06

SD-17.5-4D-W25-SOLT06

SD-18-4D-W25-SOLT06

SD-18.5-4D-W25-SOLT06

SD-19-4D-W25-SOLT06

SD-19.5-4D-W25-SOLT06

PAFANA INSERTS: SOLT 06T206…

SD-20-4D-W25-SOLT07

SD-20.5-4D-W25-SOLT07

SD-21-4D-W25-SOLT07

SD-21.5-4D-W25-SOLT07

SD-22-4D-W25-SOLT07

SD-22.5-4D-W25-SOLT07

SD-23-4D-W25-SOLT07

PAFANA INSERTS: SOLT 070308…

SD-23.5-4D-W32-SOLT08

SD-24-4D-W32-SOLT08

SD-24.5-4D-W32-SOLT08

SD-25-4D-W32-SOLT08

SD-25.5-4D-W32-SOLT08

SD-26-4D-W32-SOLT08

SD-26.5-4D-W32-SOLT08

SD-27-4D-W32-SOLT08

SD-27.5-4D-W32-SOLT08

SD-28-4D-W32-SOLT08

PAFANA INSERTS: SOLT 080308…

SD-28.5-4D-W32-SOLT10

SD-29-4D-W32-SOLT10

SD-29.5-4D-W32-SOLT10

SD-30-4D-W32-SOLT10

SD-30.5-4D-W40-SOLT10

SD-31-4D-W40-SOLT10

SD-31.5-4D-W40-SOLT10

SD-32-4D-W40-SOLT10

SD-32.5-4D-W40-SOLT10

SD-33-4D-W40-SOLT10

PAFANA INSERTS: SOLT 10T308…

SD-33.5-4D-W40-SOLT11

SD-34-4D-W40-SOLT11

SD-34.5-4D-W40-SOLT11

SD-35-4D-W40-SOLT11

SD-35.5-4D-W40-SOLT11

SD-36-4D-W40-SOLT11

SD-36.5-4D-W40-SOLT11

SD-37-4D-W40-SOLT11

SD-37.5-4D-W40-SOLT11

SD-38-4D-W40-SOLT11

PAFANA INSERTS: SOLT 110408…

SD-38.5-4D-W40-SOLT13

SD-39-4D-W40-SOLT13

SD-39.5-4D-W40-SOLT13

SD-40-4D-W40-SOLT13

SD-40.5-4D-W40-SOLT13

SD-41-4D-W40-SOLT13

SD-41.5-4D-W40-SOLT13

SD-42-4D-W40-SOLT13

SD-42.5-4D-W40-SOLT13

SD-43-4D-W40-SOLT13

SD-43.5-4D-W40-SOLT13

SD-44-4D-W40-SOLT13

PAFANA INSERTS: SOLT 130508…

ASSORTMENT – 5D:

SD-14-5D-W20-SOLT05

SD-14.5-5D-W20-SOLT05

SD-15-5D-W20-SOLT05

SD-15.5-5D-W20-SOLT05

SD-16-5D-W20-SOLT05

SD-16.5-5D-W20-SOLT05

PAFANA INSERTS: SOLT 050204…

SD-17-5D-W20-SOLT06

SD-17.5-5D-W25-SOLT06

SD-18-5D-W25-SOLT06

SD-18.5-5D-W25-SOLT06

SD-19-5D-W25-SOLT06

SD-19.5-5D-W25-SOLT06

PAFANA INSERTS: SOLT 06T206…

SD-20-5D-W25-SOLT07

SD-20.5-5D-W25-SOLT07

SD-21-5D-W25-SOLT07

SD-21.5-5D-W25-SOLT07

SD-22-5D-W25-SOLT07

SD-22.5-5D-W25-SOLT07

SD-23-5D-W25-SOLT07

PAFANA INSERTS: SOLT 070308…

SD-23.5-5D-W32-SOLT08

SD-24-5D-W32-SOLT08

SD-24.5-5D-W32-SOLT08

SD-25-5D-W32-SOLT08

SD-25.5-5D-W32-SOLT08

SD-26-5D-W32-SOLT08

SD-26.5-5D-W32-SOLT08

SD-27-5D-W32-SOLT08

SD-27.5-5D-W32-SOLT08

SD-28-5D-W32-SOLT08

PAFANA INSERTS: SOLT 080308…

SD-28.5-5D-W32-SOLT10

SD-29-5D-W32-SOLT10

SD-29.5-5D-W32-SOLT10

SD-30-5D-W32-SOLT10

SD-30.5-5D-W40-SOLT10

SD-31-5D-W40-SOLT10

SD-31.5-5D-W40-SOLT10

SD-32-5D-W40-SOLT10

SD-32.5-5D-W40-SOLT10

SD-33-5D-W40-SOLT10

PAFANA INSERTS: SOLT 10T308…

SD-33.5-5D-W40-SOLT11

SD-34-5D-W40-SOLT11

SD-34.5-5D-W40-SOLT11

SD-35-5D-W40-SOLT11

SD-35.5-5D-W40-SOLT11

SD-36-5D-W40-SOLT11

SD-36.5-5D-W40-SOLT11

SD-37-5D-W40-SOLT11

SD-37.5-5D-W40-SOLT11

SD-38-5D-W40-SOLT11

PAFANA INSERTS: SOLT 110408…

SD-38.5-5D-W40-SOLT13

SD-39-5D-W40-SOLT13

SD-39.5-5D-W40-SOLT13

SD-40-5D-W40-SOLT13

SD-40.5-5D-W40-SOLT13

SD-41-5D-W40-SOLT13

SD-41.5-5D-W40-SOLT13

SD-42-5D-W40-SOLT13

SD-42.5-5D-W40-SOLT13

SD-43-5D-W40-SOLT13

SD-43.5-5D-W40-SOLT13

SD-44-5D-W40-SOLT13

PAFANA INSERTS: SOLT 130508…

Pafana new – half drills enriching the assortment enabling the preparation of holes for typical metric threads.

PAFANA INSERTS ASSORTMENT SOLT:

SOLT 05 02 04 WSP FP30S (P)

SOLT 05 02 04 WSP FM35M (M), FM35M (K(S))

SOLT 05 02 04 WSM FM35M (M)

SOLT 05 02 04 WSK FK15H (K)

SOLT 06 T2 06 WSP FP30S (P)

SOLT 06 T2 06 WSP FM35M (M), FM35M (K(S))

SOLT 06 T2 06 WSM FM35M (M)

SOLT 06 T2 06 WSK FK15H (K)

SOLT 07 03 08 WSP FP30S (P)

SOLT 07 03 08 WSP FM35M (M), FM35M (K(S))

SOLT 07 03 08 WSM FM35M (M)

SOLT 07 03 08 WSK FK15H (K)

SOLT 08 03 08 WSP FP30S (P)

SOLT 08 03 08 WSP FM35M (M), FM35M (K(S))

SOLT 08 03 08 WSM FM35M (M

SOLT 08 03 08 WSK FK15H (K)

SOLT 10 T3 08 WSP FP30S (P)

SOLT 10 T3 08 WSP FM35M (M), FM35M (K(S))

SOLT 10 T3 08 WSM FM35M (M

SOLT 10 T3 08 WSK FK15H (K)

SOLT 11 04 08 WSP FP30S (P)

SOLT 11 04 08 WSP FM35M (M), FM35M (K(S))

SOLT 11 04 08 WSM FM35M (M

SOLT 11 04 08 WSK FK15H (K)

SOLT 13 05 08 WSP FP30S (P)

SOLT 13 05 08 WSP FM35M (M), FM35M (K(S))

SOLT 13 05 08 WSM FM35M (M

SOLT 13 05 08 WSK FK15H (K)

see the PAFANA on-line catalog: http://pafana.elkat.eu/#0

see the assortment of the PAFANA catalog edition 07/2020: https://pafana.pl/en/products/indexable-insert-drills-indexable-inserts-drills-of-pafana-indexable-insert-drills-of-pafana-l-3d-sd-solt-with-pafana-indexable-inserts-solt-indexable-insert-drills-of-pafana-l-2d-r8/

see PAFANA news: https://pafana.pl/en/products/new/

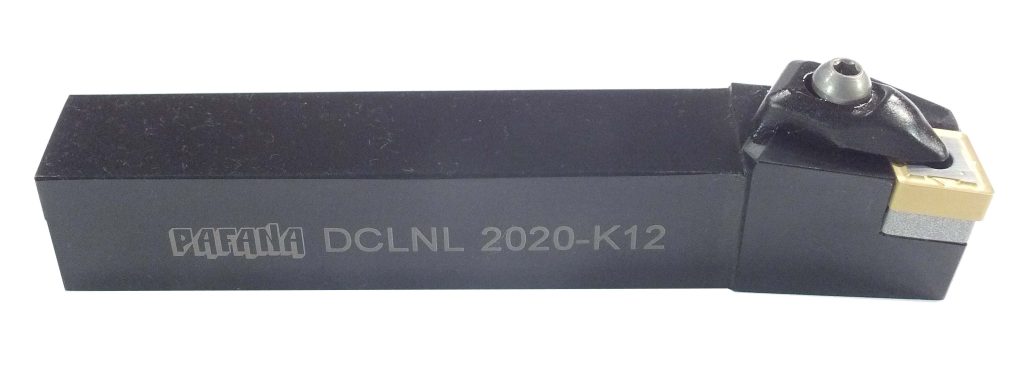

SYSTEM – “D” – PAFANA.`

1 – holder. 2 – shim. 3 – shim locking screw.

4 – clamp. 5 – locking screw. 6 – spring. 7 – cutting insert.

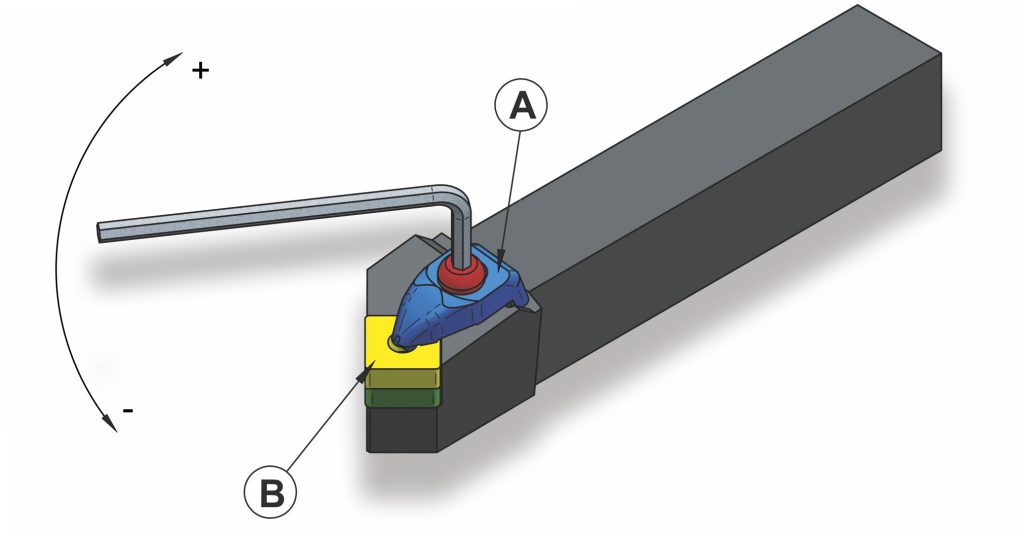

CLAMPING SYSTEM FOR INSERTS – “D” – PAFANA.

SYSTEM “D”- negative geometry of toolholders. Negative indexable inserts (insert clearance angle 0°) are locked with a special clamp at the same time in two direction, i.e. on the surface of the cylindrical hole of the insert and on the rake face.

Toolholders with inserts clamped in the “D”system are the best choice for effective machining, both roughing and finishing, requiring the highest rigidity and stability of insert position. They are used for external turning and cutting holes.

The system “D” is characterised by a very good repeatability of cutting-edge position, easy and quick replacement of cutting insert.

The shim and cutting insert are fixed only with one key.

REPLACEMENT OF INDEXABLE INSERTS IN THE TOOLHOLDERS OF SYSTEM – “D” – PAFANA.

1. Unscrew the clamp (A), in order to enable turning or replacing the insert (B).

2. Turn or replace the insert (B).

3. Screw on the clamp (A).

ASSORTMENT – SYSTEM – “D” – PAFANA.

Assortment of clamp-type toolholders available (external turning) – System – D – Pafana:

DCLNR/L 2020K12

DCLNR 2020K12

DCLNL 2020K12

DCLNR/L 2525M12

DCLNR 2525M12

DCLNL 2525M12

DCLNR/L 3232P12

DCLNR 3232P12

DCLNL 3232P12

DDJNR/L 2020K15

DDJNR 2020K15

DDJNL 2020K15

DDJNR/L 2525M15

DDJNR 2525M15

DDJNL 2525M15

DDJNR/L 3232P15

DDJNR 3232P15

DDJNL 3232P15

DSSNR/L 2020K12

DSSNR 2020K12

DSSNL 2020K12

DSSNR/L 2525M12

DSSNR 2525M12

DSSNL 2525M12

DSSNR/L 3225P12

DSSNR 3225P12

DSSNL 3225P12

DTGNR/L 2020K16

DTGNR 2020K16

DTGNL 2020K16

DTGNR/L 2525M16

DTGNR 2525M16

DTGNL 2525M16

DTGNR/L 3225P16

DTGNR 3225P16

DTGNL 3225P16

DTJNR/L 2020K16

DTJNR 2020K16

DTJNL 2020K16

DTJNR/L 2525M16

DTJNR 2525M16

DTJNL 2525M16

DTJNR/L 3225P16

DTJNR 3225P16

DTJNL 3225P16

DWLNR/L 2020K06

DWLNR 2020K06

DWLNL 2020K06

DWLNR/L 2020K08

DWLNR 2020K08

DWLNL 2020K08

DWLNR/L 2525M08

DWLNR 2525M08

DWLNL 2525M08

DWLNR/L 3225P08

DWLNR 3225P08

DWLNL 3225P08

PAFANA (REMOVABLE) INDEXABLE INSERTS.

Indexable cutting inserts in the following shapes:

Available on the pages of the Pafana Product Catalogue, edition 07/2020.

CN.. 1204..

DN.. 1506..

SN.. 1204..

TN.. 1604..

WN.. 0804..

Pafana insert sorts available:

C insert shape.

Chipbreaker SSP sort BP30S – for steel, sort BK20S for cast iron,

Chipbreaker SS sort BP30A, BP35A – for steel,

Chipbreaker ZSP sort BP30S, BP35S – for steel, sort BK10S, BK20S – for cast iron,

Chipbreaker ZSS sort BP20S, BP30S – for steel,

Chipbreaker STK sort FM30S – for corrosion resistant steel,

Chipbreaker STR sort FM30S – for corrosion resistant steel,

Chipbreaker SU sort FK25W – for corrosion resistant steel,

Chipbreaker EN sort BK10S, BK20S – for cast iron,

Chipbreaker FN-DNE sort NK20M – for aluminium,

Chipbreaker STE sort FM10I, FM15I – for heat resistant alloys.

D insert shape.

Chipbreaker SSP sort BP30S – for steel, sort BK20S for cast iron,

Chipbreaker SS sort BP30A, BP35A – for steel,

Chipbreaker ZSS sort BP20S, BP30S – for steel,

Chipbreaker DNP sort FM20A – for corrosion resistant steel,

Chipbreaker STK sort FM30S – for corrosion resistant steel,

Chipbreaker STR sort FM30S – for corrosion resistant steel,

Chipbreaker ZSP sort BK20S – for cast iron,

Chipbreaker FN-DNE sort NK20M – for aluminium,

Chipbreaker STE sort FM10I, FM15I – for heat resistant alloys.

S insert shape.

Chipbreaker SSP sort BP20S, BP30S, BP35S – for steel, sort BK20S for cast iron,

Chipbreaker SS sort BP30A, BP35A – for steel,

Chipbreaker ZSS sort BP30S – for steel,

Chipbreaker ZSP sort BK10S – for cast iron,

Chipbreaker ZSZ sort BP35A – for steel,

Chipbreaker EN sort BK20S – for cast iron,

Chipbreaker SU sort FK25W – for corrosion resistant steel,

Chipbreaker STK sort FM30S – for corrosion resistant steel,

FM10I, FM15I – for heat resistant alloys,

Chipbreaker STE sort FM10I, FM15I – for heat resistant alloys.

T insert shape.

Chipbreaker SSP sort BP20S, BP30S – for steel, sort BK20S for cast iron,

Chipbreaker SS sort BP30A, BP35A – for steel,

Chipbreaker ZSP sort BK20S – for cast iron,

Chipbreaker ZSS sort BP30S – for steel,

Chipbreaker ZSZ sort BP30A, BP35A – for steel,

Chipbreaker ER/EL sort BP30A – for steel,

Chipbreaker STK sort FM30S – for corrosion resistant steel,

Chipbreaker STR sort FM30S – for corrosion resistant steel,

Chipbreaker EN sort BK20S – for cast iron,

Chipbreaker STE sort FM10I, FM15I – for heat resistant alloys.

W insert shape.

Chipbreaker SSP sort BP20S, BP30S, BP35S – for steel, sort BK20S for cast iron,

Chipbreaker SS sort BP30A, BP35A – for steel,

Chipbreaker ZSP sort BK10S, BK20S – for cast iron,

Chipbreaker ZSS sort BP30S – for steel,

Chipbreaker ZSZ sort BP30A – for steel, sort BK20S – for cast iron,

Chipbreaker DNP sort FM20A – for corrosion resistant steel,

Chipbreaker FN-DNE sort FM20A – for corrosion resistant steel,

sort NK20M – for aluminium,

Chipbreaker STK sort FM30S – for corrosion resistant steel,

Chipbreaker STR sort FM30S – for corrosion resistant steel,

Chipbreaker SU sort FK25W – for corrosion resistant steel,

Chipbreaker FN-DNE sort NK20M – for aluminium,

Chipbreaker STE sort FM10I, FM15I – for heat resistant alloys.

Assortment of boring tools available (internal turning),

boring tools with fully ground shanks – system – D – Pafana:

A25R-DCLNR/L 12

A25R-DCLNR 12

A25R-DCLNL 12

A32S-DCLNR/L 12

A32S-DCLNR 12

A32S-DCLNL 12

A20Q-DTFNR/L 16

A20Q-DTFNR 16

A20Q-DTFNL 16

A25R-DTFNR/L 16

A25R-DTFNR 16

A25R-DTFNL 16

A32S-DTFNR/L 16

A25R-DTFNR 16

A25R-DTFNL 16

A40T-DTFNR/L 16

A40T-DTFNR 16

A40T-DTFNL 16

A25R-DWLNR/L 08

A25R-DWLNR 08

A25R-DWLNL 08

A32S-DWLNR/L 08

A32S-DWLNR 08

A32S-DWLNL 08

A40V-DWLNR/L 08

A40V-DWLNR 08

A40V-DWLNL 08

(boring tools with diameters d = 16-32 mm are equipped with a plug sealing – the coolant supply to zone of machining)

note! – toolholders with through the-bar coolant system to zone of machining.

PAFANA (REMOVABLE) INDEXABLE INSERTS.

Indexable cutting inserts in the following shapes:

Available on the pages of the Pafana Product Catalogue, edition 07/2020.

CN.. 1204.

TN.. 1604..

WN.. 0804..

Pafana insert sorts available:

C insert shape.

Chipbreaker SSP sort BP30S – for steel, sort BK20S for cast iron,

Chipbreaker SS sort BP30A, BP35A – for steel,

Chipbreaker ZSP sort BP30S, BP35S – for steel, sort BK10S, BK20S – for cast iron,

Chipbreaker ZSS sort BP20S, BP30S – for steel,

Chipbreaker STK sort FM30S – for corrosion resistant steel,

Chipbreaker STR sort FM30S – for corrosion resistant steel,

Chipbreaker SU sort FK25W – for corrosion resistant steel,

Chipbreaker EN sort BK10S, BK20S – for cast iron,

Chipbreaker FN-DNE sort NK20M – for aluminium,

Chipbreaker STE sort FM10I, FM15I – for heat resistant alloys.

T insert shape.

Chipbreaker SSP sort BP20S, BP30S – for steel, sort BK20S for cast iron,

Chipbreaker SS sort BP30A, BP35A – for steel,

Chipbreaker ZSP sort BK20S – for cast iron,

Chipbreaker ZSS sort BP30S – for steel,

Chipbreaker ZSZ sort BP30A, BP35A – for steel,

Chipbreaker ER/EL sort BP30A – for steel,

Chipbreaker STK sort FM30S – for corrosion resistant steel,

Chipbreaker STR sort FM30S – for corrosion resistant steel,

Chipbreaker EN sort BK20S – for cast iron,

Chipbreaker STE sort FM10I, FM15I – for heat resistant alloys.

W insert shape.

Chipbreaker SSP sort BP20S, BP30S, BP35S – for steel, sort BK20S for cast iron,

Chipbreaker SS sort BP30A, BP35A – for steel,

Chipbreaker ZSP sort BK10S, BK20S – for cast iron,

Chipbreaker ZSS sort BP30S – for steel,

Chipbreaker ZSZ sort BP30A – for steel, sort BK20S – for cast iron,

Chipbreaker DNP sort FM20A – for corrosion resistant steel,

Chipbreaker FN-DNE sort FM20A – for corrosion resistant steel,

sort NK20M – for aluminium,

Chipbreaker STK sort FM30S – for corrosion resistant steel,

Chipbreaker STR sort FM30S – for corrosion resistant steel,

Chipbreaker SU sort FK25W – for corrosion resistant steel,

Chipbreaker FN-DNE sort NK20M – for aluminium,

Chipbreaker STE sort FM10I, FM15I – for heat resistant alloys.

SPARE PARTS SYSTEM – “D” – PAFANA.

Spare part assortment:

Shim – 123.26-622,

Shim – 171.66-624,

Shim – 175.10-621,

Shim – DWN-08,

Shim locking screw – DSS-5,

Shim locking screw – 174.10-650,

Clamp – DC-4,

Docisk – DC-5,

Clamp screw – DS-4,

Clamp screw – DS-5,

Spring – DP-4,

Spring – DP-5,

Key – 2SMS,.

Key – 3SMS

see the PAFANA on-line catalog: http://pafana.elkat.eu/#0

see the assortment of the PAFANA catalog edition 07/2020: https://pafana.pl/en/products/toolholders-clamping-systems-for-inserts-system-s-boring-bars-with-sintered-carbide-shank-tool-holders-vdi-pta-20-28-boring-cartridges-toolholders-for-automatic-lathes-system-p-p-k-d-m-c-system-c-to/

see PAFANA news: https://pafana.pl/en/products/new/

AVAILABILITY.

THE WHOLE ASSORTMENT IS AVAILABLE FROM THE PAFANA WAREHOUSE.

WE INVITE YOU.

We invite you to cooperate and buy, of course, this stable, durable system will work in many machining activities in your companies.

3.1. BORING MODULAR SYSTEM “MULTI PAFANA”.

BORING SET NWGW 10300.

BORING MODULAR SYSTEM “MULTI PAFANA”.

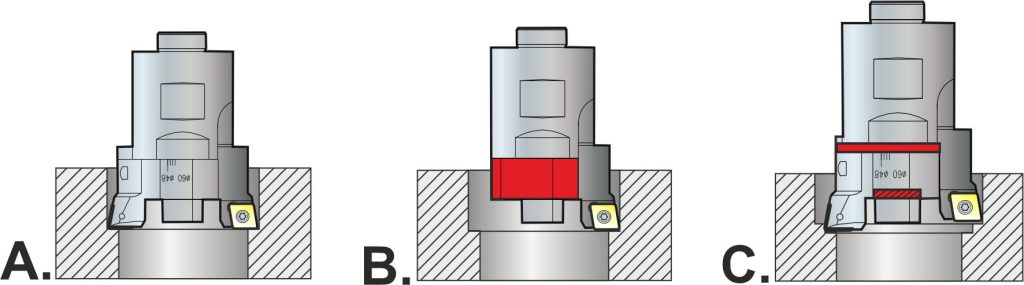

ADVANTAGES AND APPLICATION:

- Versatility – possibility of mounting both rough and finishing boring heads at the same shanks – in the entire diameter range.

- Stiffness – high stiffness of all boring set.

3. Possibility of boring length increasing by using e.g. two extension bars.

4. Application of indexable inserts according to ISO standards.

5. With the same tools one can realise:

A. Twin edge boring – high efficiency.

B. Single edge boring.

C. Stepped boring.

Information required configuring the BORING MODULAR SYSTEM “MULTI PAFANA”:

– Shanks type,

– Range of boring diameters,

– Boring length,

– Machining type,

– Max. tool weight in the spindle,

– Workpiece.

An inquiry configured in this way, reaching the Pafana Technical and Commercial Advisor, enables the selection of the appropriate boring tool for the customer’s machining needs.

We invite you: link to the Map of Regions Operations of Technical and Commercial Advisors of PAFANA S.A.

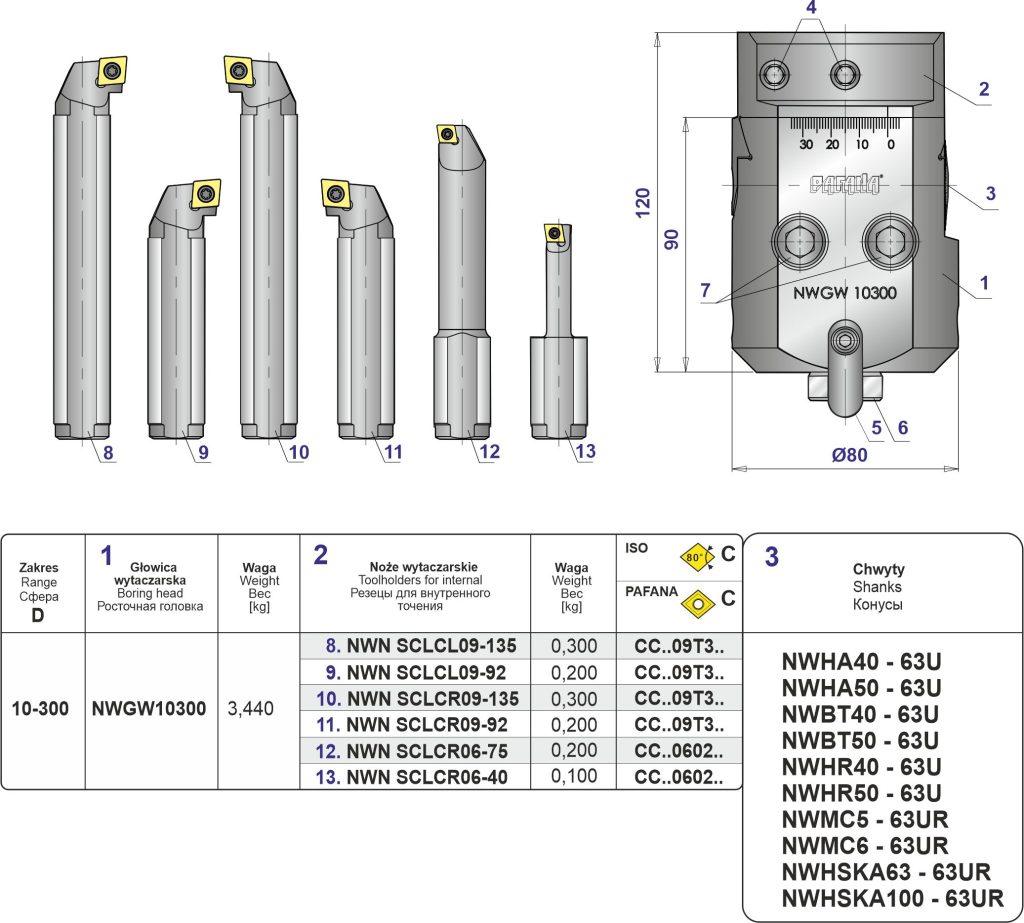

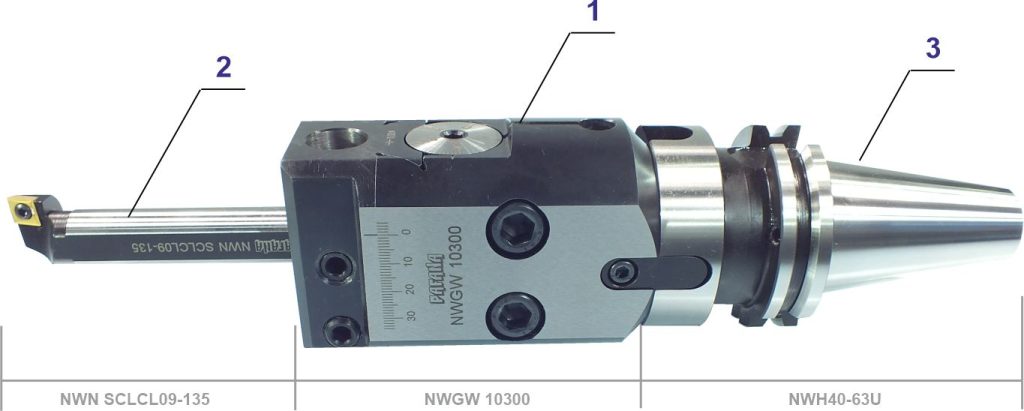

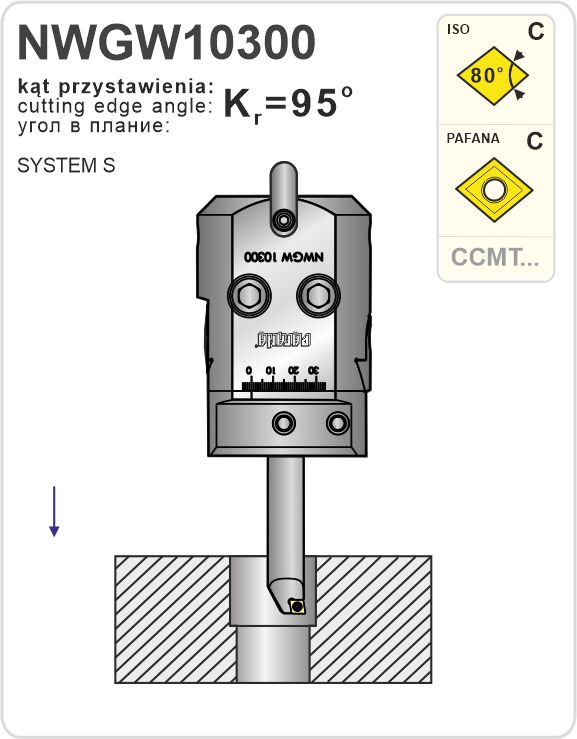

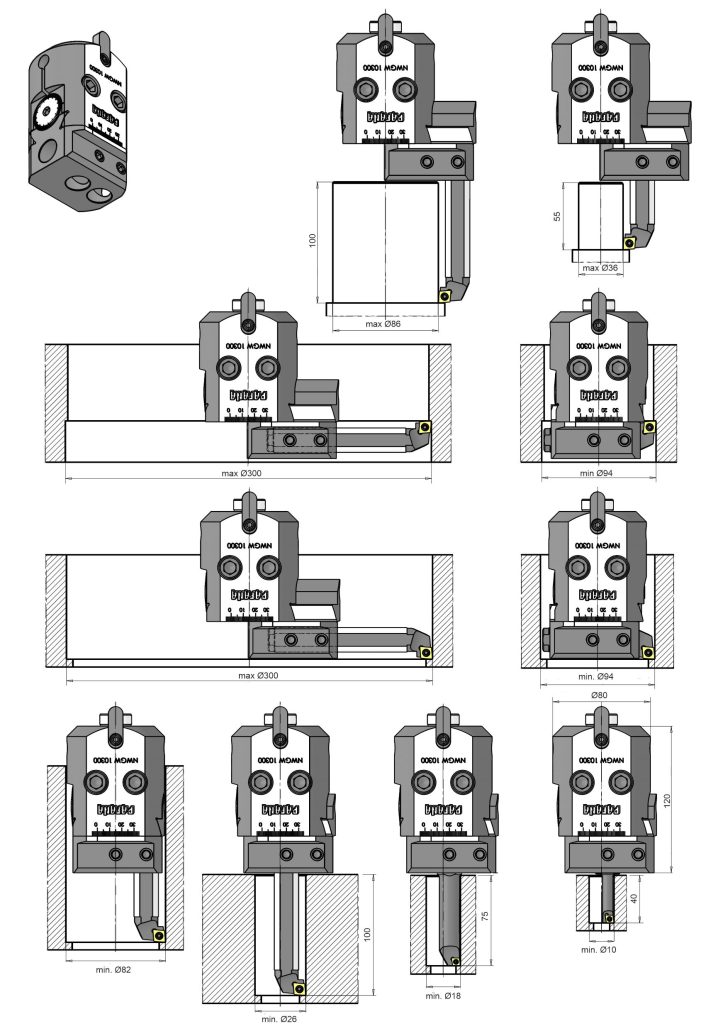

ONE OF THE COMPONENTS OF THE “MULTIPAFANA” BORING SYSTEM IS THE NWGW 10300 BORING SET.

Benefits for the customer:

1. Wide range of boring from 10 to 300 mm.

2. Boring precision of 0.02 mm per diameter.

3. The head is compatible and installed to boring taper shanks from boring system MULTI PAFANA.

4. Professional set equipment allows:

– boring holes from 10 to 300 mm,

– reverse (return) boring from 94 to 300 mm,

– turning cylindrical surfaces (pivots) of up to 86 mm.

5. The following inserts acc. to ISO type are mounted in the toolholders being part of head equipment

– CC.. 0602…

– CC.. 09T3…

APPLICATION RANGE:

THE SET IS PACKED IN A DURABLE PACKAGING IN THE FORM OF A SUITCASE.

ASSORTMENT:

BORING HEAD NWGW10300

TOOLHOLDERS FOR INTERNAL:

NWN SCLCL09-135

NWN SCLCL09-92

NWN SCLCR09-135

NWN SCLCR09-92

PAFANA INSERTS CC.. 09T3…

CCMT 09T302 SDS BP30S (P), FM30S (M),

CCMT 09T304 SDS BP20S (P), BP30S (P), FM30S (M),

CCMT 09T308 SDS BP30S (P), FM30S (M),

CCMT 09T304 SSP BP20S (P), BP30S (P), FM30S (M), BK20S (K),

CCMT 09T308 SSP BP20S (P), BP30S (P), FM30S (M), BK20S (K),

CCMT 09T304 SS BP30A (P), BP35A (P),

CCMT 09T308 SS BP30A (P), BP35A (P),

CCMT 09T304 SW1 BP30A (P), BP35A (P),

CCMT 09T308 SW1 BP30A (P), BP35A (P),

CCGT 09T304 FN-AP NK10A (K(N)),

CCGT 09T302 FN-AP NK10A (K(N)),

CCGT 09T308 FN-AP NK10A (K(N)),

CCGT 09T304 FN-AL NK15A (K(N)),

CCGT 09T308 FN-AL NK15A (K(N)),

CCGT 09T300 DD FM20A (M).

TOOLHOLDERS FOR INTERNAL:

NWN SCLCR06-75

NWN SCLCR06-40

PAFANA INSERTS CC.. 0602…

CCMT 060202 SDS BP30S (P), FM30S (M),

CCMT 060204 SDS BP20S (P), BP30S (P), FM30S (M),

CCMT 060204 SSP BP30S (P), BP35S (P), FM30S (M), BK20S (K),

CCMT 060208 SSP BP30S (P), BP35S (P), FM30S (M), BK20S (K),

CCMT 060204 SS BP30A (P), BP35A (P),

CCMT 060208 SS BP30A (P), BP35A (P),

CCMT 060204 SW1 BP30A (P), BP35A (P),

CCMT 060208 SW1 BP30A (P), BP35A (P),

CCGT 060201 FN-AL NK15A (K(N)),

CCGT 060202 FN-AP NK10A (K(N)),

CCGT 060204 FN-AP NK10A (K(N)),

CCGT 060201 DD FM20A (M).

SHANKS:

NWHA40 – 63U

NWHA50 – 63U

NWBT40 – 63U

NWBT50 – 63U

NWHR40 – 63U

NWHR50 – 63U

NWMC5 – 63UR

NWMC6 – 63UR

NWHSKA63 – 63UR

NWHSKA100 – 63UR

see the PAFANA on-line catalog: http://pafana.elkat.eu/#0

see the assortment of the PAFANA catalog edition 07/2020: https://pafana.pl/en/products/boring-bars-of-pafana-boring-modular-system-multi-pafana/

see PAFANA news: https://pafana.pl/en/products/new/

WE INVITE YOU.

MARKETING AND EXPORT DEPARTMENT OF PFN PAFANA S.A.

e-mail: marketing@pafana.pl

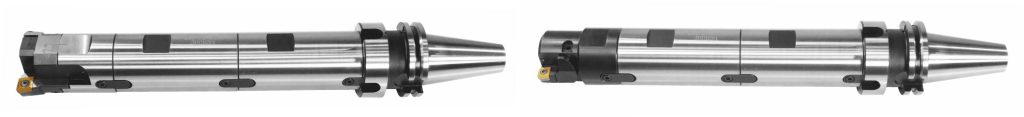

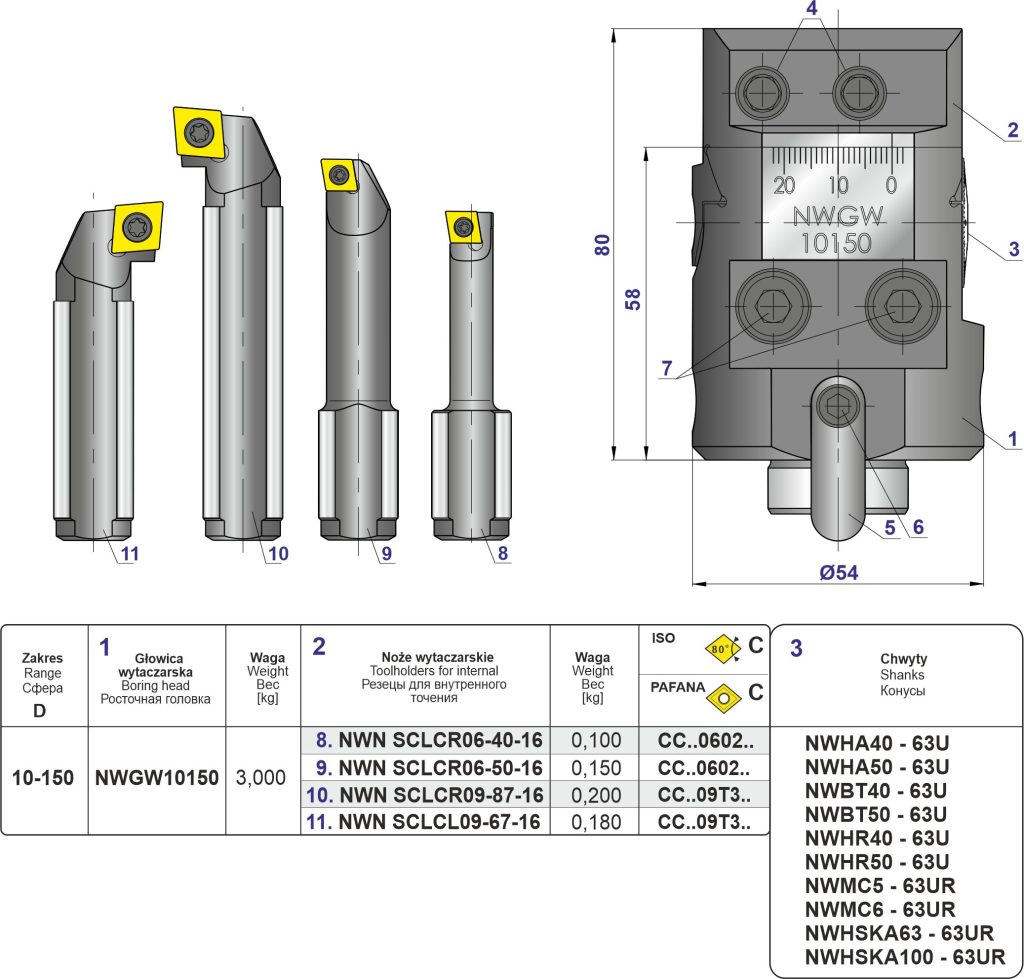

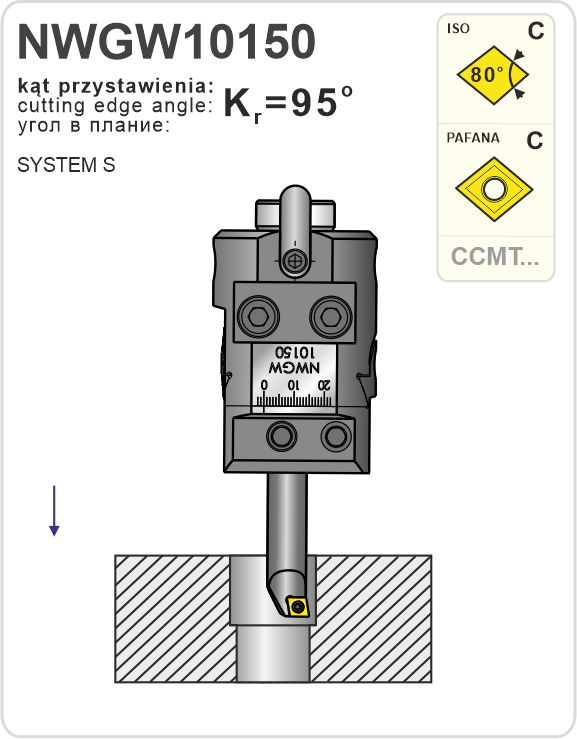

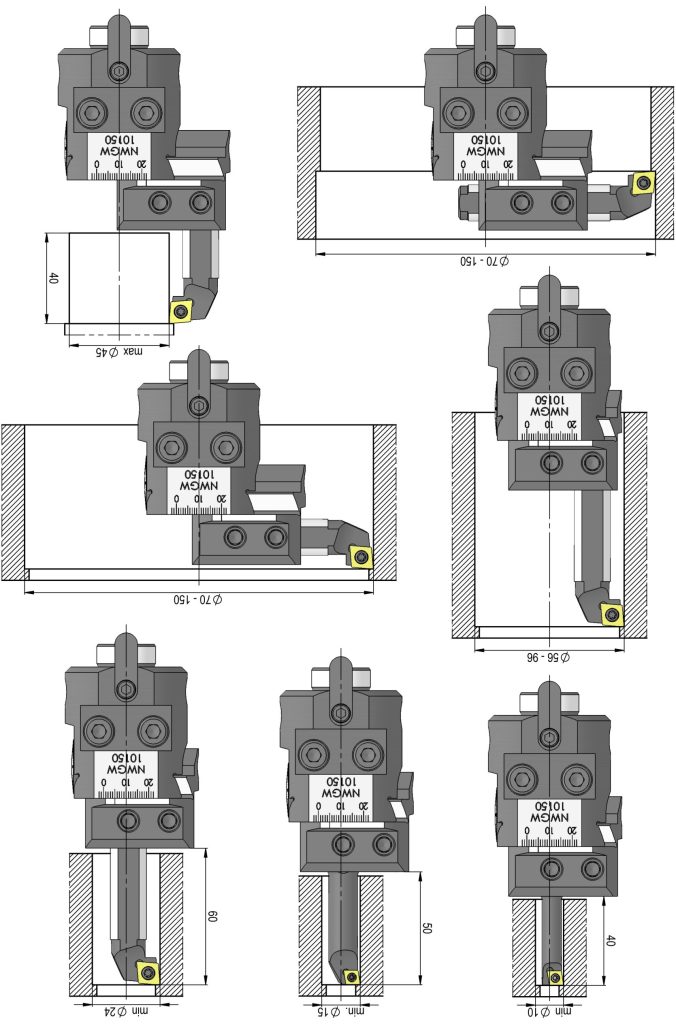

3.1. BORING MODULAR SYSTEM “MULTI PAFANA”.

BORING SET NWGW 10150.

Benefits for the customer:

1. Wide range of boring from 10 to 150 mm.

2. Boring precision of 0.02 mm per diameter.

3. The head is compatible and installed to boring taper shanks from boring system MULTI PAFANA.

4. Professional set equipment allows:

– boring holes from 10 to 150 mm,

– reverse (return) boring from 94 to 150 mm,

– turning cylindrical surfaces (pivots) with diameter of up to Ø45 and length of up to 40 mm.

5. The following inserts acc. to ISO type are mounted in the toolholders being part of head equipment

– CC.. 0602…

– CC.. 09T3…

APPLICATION RANGE:

THE SET IS PACKED IN A DURABLE PACKAGING IN THE FORM OF A SUITCASE.

ASSORTMENT:

BORING HEAD NWGW10150

TOOLHOLDERS FOR INTERNAL:

NWN SCLCR06-40-16

NWN SCLCR06-50-16

PAFANA INSERTS: CC..0602…

CCMT 060204 DS1 CRP10A (P),

CCMT 060202 SDS BP30S (P), FM30S (M),

CCMT 060204 SDS BP20S (P), BP30S (P), FM30S (M),

CCMT 060204 SSP BP30S (P), BP35S (P), FM30S (M), BK20S (K),

CCMT 060208 SSP BP30S (P), BP35S (P), FM30S (M), BK20S (K),

CCMT 060204 SS BP30A (P), BP35A (P),

CCMT 060208 SS BP30A (P), BP35A (P),

CCMT 060204 SW1 BP30A (P), BP35A (P),

CCMT 060208 SW1 BP30A (P), BP35A (P),

CCGT 060201 FN-AL NK15A (K(N)),

CCGT 060202 FN-AP NK10A (K(N)),

CCGT 060204 FN-AP NK10A (K(N)),

CCGT 060201 DD FM20A (M).

TOOLHOLDERS FOR INTERNAL:

NWN SCLCR09-87-16

NWN SCLCL09-67-16

PAFANA INSERTS: CC..09T3…

CCMT 09T304 DS1 CRP10A (P),

CCMT 09T302 SDS BP30S (P), FM30S (M),

CCMT 09T304 SDS BP20S (P), BP30S (P), FM30S (M),

CCMT 09T308 SDS BP30S (P), FM30S (M),

CCMT 09T304 SSP BP20S (P), BP30S (P), FM30S (M), BK20S (K),

CCMT 09T308 SSP BP20S (P), BP30S (P), FM30S (M), BK20S (K),

CCMT 09T304 SS BP30A (P), BP35A (P),

CCMT 09T308 SS BP30A (P), BP35A (P),

CCMT 09T304 SW1 BP30A (P), BP35A (P),

CCMT 09T308 SW1 BP30A (P), BP35A (P),

CCGT 09T304 FN-AP NK10A (K(N)),

CCGT 09T302 FN-AP NK10A (K(N)),

CCGT 09T308 FN-AP NK10A (K(N)),

CCGT 09T304 FN-AL NK15A (K(N)),

CCGT 09T308 FN-AL NK15A (K(N)),

CCGT 09T300 DD FM20A (M).

SHANKS:

NWHA40 – 63U

NWHA50 – 63U

NWBT40 – 63U

NWBT50 – 63U

NWHR40 – 63U

NWHR50 – 63U

NWMC5 – 63UR

NWMC6 – 63UR

NWHSKA63 – 63UR

NWHSKA100 – 63UR

see the PAFANA on-line catalog: http://pafana.elkat.eu/#0

see the assortment of the PAFANA catalog edition 07/2020: https://pafana.pl/en/products/boring-bars-of-pafana-boring-modular-system-multi-pafana/

see PAFANA news: https://pafana.pl/en/products/new/

WE INVITE YOU.

MARKETING AND EXPORT DEPARTMENT OF PFN PAFANA S.A.

e-mail: marketing@pafana.pl

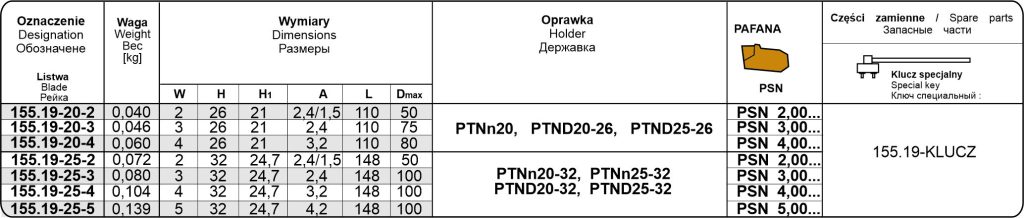

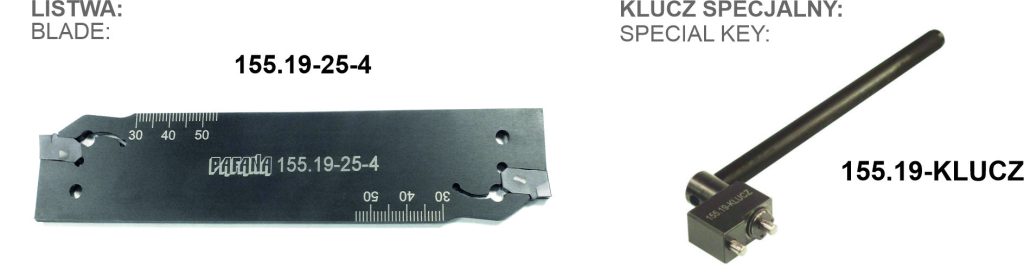

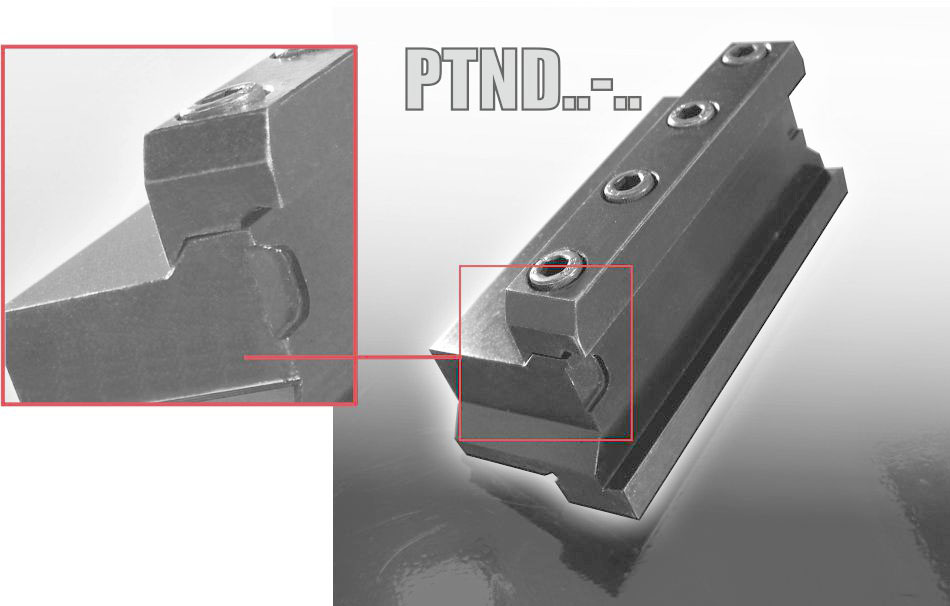

STRONG BLADE SYSTEM.

TOOLHOLDERS FOR PARTING, UNDERCUTTING, GROOVING.

Blade 155.19-..-.

USING:

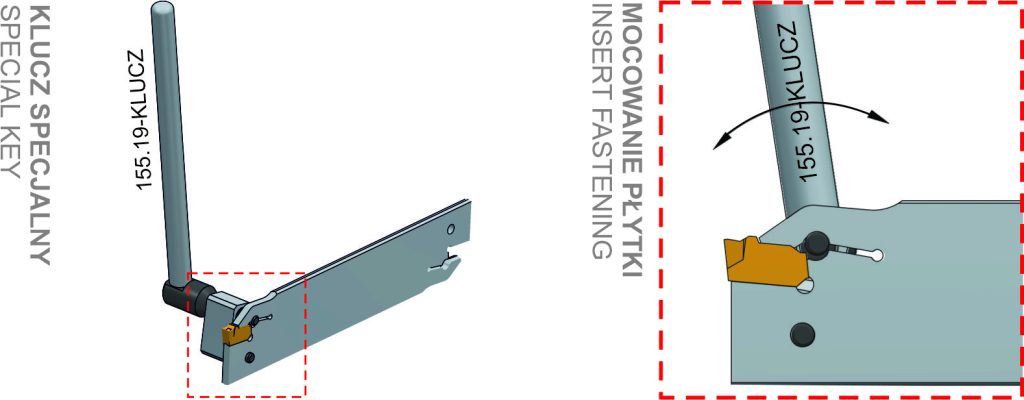

The toolholders – partings-off 155.19-..-. with changeable inserts PSN clamped toolholders by restoring forces are modern tools for parting objects with large diameters and for making depth radial undercuts.

The insert is fastened in the tool seat with a special key (155.19-KEY) by which the fastening surfaces are “unclenched”.

PAFANA INSERTS: PSN…

ASSORTMENT:

BLADE 155.19-20-2

INSERTS OF PAFANA: PSN 2,00S-0,20M2 BP35H (P), FP40H (P), FP40H (M), BP35H (K), PSN 2,00F-0,20ALU NK15A (K(N)).

HOLDERS: PTNn20, PTND20-26, PTND25-26

SPECIAL KEY: 155.19-KLUCZ.

BLADE 155.19-20-3

INSERTS OF PAFANA: PSN 3,00S-0,30M2 BP35H (P), FP40H (P), FP40H (M), BP35H (K), PSN 3,00F-0,30ALU NK15A (K(N)).

HOLDERS: PTNn20, PTND20-26, PTND25-26.

SPECIAL KEY: 155.19-KLUCZ.

BLADE 155.19-20-4

INSERTS OF PAFANA: PSN 4,00S-0,40M2 BP35H (P), FP40H (P), FP40H (M), BP35H (K), PSN 4,00F-0,40ALU NK15A (K(N)).

HOLDERS: PTNn20, PTND20-26, PTND25-26.

SPECIAL KEY: 155.19-KLUCZ.

BLADE 155.19-25-2

INSERTS OF PAFANA: PSN 2,00S-0,20M2 BP35H (P), FP40H (P), FP40H (M), BP35H (K), PSN 2,00F-0,20ALU NK15A (K(N)).

HOLDERS: PTND20-32, PTND25-32, PTNn20-32, PTNn25-32.

SPECIAL KEY: 155.19-KLUCZ.

BLADE 155.19-25-3

INSERTS OF PAFANA: PSN 3,00S-0,30M2 BP35H (P), FP40H (P), FP40H (M), BP35H (K), PSN 3,00F-0,30ALU NK15A (K(N)).

HOLDERS: PTND20-32, PTND25-32, PTNn20-32, PTNn25-32.

SPECIAL KEY: 155.19-KLUCZ.

BLADE 155.19-25-4

INSERTS OF PAFANA: PSN 4,00S-0,40M2 BP35H (P), FP40H (P), FP40H (M), BP35H (K), PSN 4,00F-0,40ALU NK15A (K(N)).

HOLDERS: PTND20-32, PTND25-32 PTNn20-32, PTNn25-32.

SPECIAL KEY: 155.19-KLUCZ.

BLADE 155.19-25-5

INSERTS OF PAFANA: PSN 5,00S-0,40M2 BP35H (P), FP40H (P), FP40H (M), BP35H (K).

HOLDERS: PTND 20-32, PTND25-32 PTNn20-32, PTNn25-32.

SPECIAL KEY: 155.19-KLUCZ.

ADVANTAGES:

The position of the insert on two prismatic surfaces and one flat surface, and the simultaneous installation by using restoring forces ensure very good fastening stiffness, precision and repeatability, which guarantees durability of the changeable insert and the entire tool.

1. PTND and PTNn holders should be used for the fixing of the 150.19-..-., 151.19-..-., 155.19-..-. blades.

2. Ensuring a perpendicular position of the tool in relation to the axis of the machined object is one of the most important conditions of the correct operation of the tool – fig. 1.

The cutting edge should be positioned at a height of +/-0,1 in relation to the axis of the machined object (the position above the axis is more favourable) – fig. 2.

Coolant should be strongly fed directly onto the cutting edge while machining.

see the PAFANA on-line catalog: http://pafana.elkat.eu/#0

see the assortment of the PAFANA catalog edition 07/2020: https://pafana.pl/en/products/toolholders-clamping-systems-for-inserts-system-s-boring-bars-with-sintered-carbide-shank-tool-holders-vdi-pta-20-28-boring-cartridges-toolholders-for-automatic-lathes-system-p-p-k-d-m-c-system-c-to/

see PAFANA news: https://pafana.pl/en/products/new/

Prepared by: Zdzislaw Pawlak Manager of the Marketing and Export Department of PFN PAFANA S.A. Pabianice, January 10, 2023.