07 carbide end mills pafana 2023 EN

CARBIDE END MILLS „SMart Line” PAFANA.

ASSORTMENT:

OFFER PFN PAFANA S.A.INCLUDES:

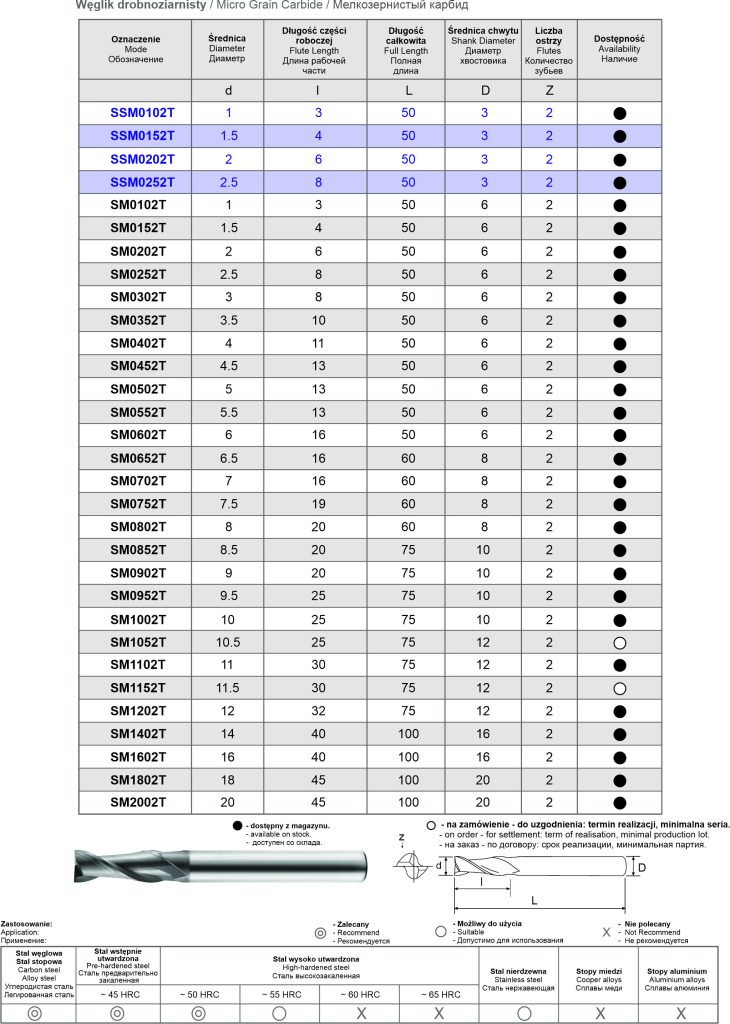

SQUARE SERIES – 2 FLUTES END MILLS.

APPLICATION:

RECOMMEND – CARBON STEEL, ALLOY STEEL, PRE-HARDENED STEL, HIGHT-HARDENED STEEL TO 50 HRC.

SUITABLE – HIGHT-HARDENED STEEL TO 55 HRC, STAINLESS STEEL.

NOT RECOMMEND – HIGHT-HARDENED STEEL FROM 60 HRC TO 65 HRC, COOPER ALLOYS, ALUMINIUM ALLOYS.

SSM0102T

SSM0152T

SSM0202T

SSM0252T

SM0102T

SM0152T

SM0202T

SM0252T

SM0302T

SM0352T

SM0402T

SM0452T

SM0502T

SM0552T

SM0602T

SM0652T

SM0702T

SM0752T

SM0802T

SM0852T

SM0902T

SM0952T

SM1002T

SM1052T

SM1102T

SM1152T

SM1202T

SM1402T

SM1602T

SM1802T

SM2002T

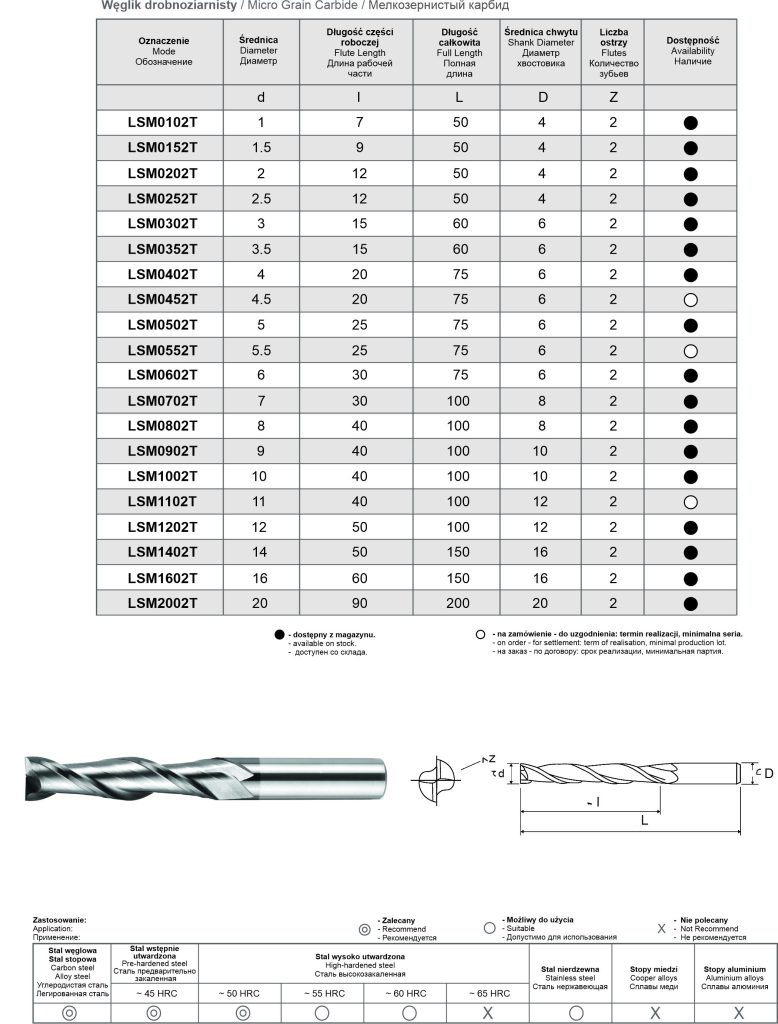

SQUARE SERIES – LONG FLUTE – 2 FLUTES END MILLS.

APPLICATION:

RECOMMEND – CARBON STEEL, ALLOY STEEL, PRE-HARDENED STEL, HIGHT-HARDENED STEEL TO 50 HRC.

SUITABLE – HIGHT-HARDENED STEEL TO 55 HRC, STAINLESS STEEL.

NOT RECOMMEND – HIGHT-HARDENED STEEL FROM 60 HRC TO 65 HRC, COOPER ALLOYS, ALUMINIUM ALLOYS.

LSM0102T

LSM0152T

LSM0202T

LSM0252T

LSM0302T

LSM0352T

LSM0402T

LSM0452T

LSM0502T

LSM0552T

LSM0602T

LSM0702T

LSM0802T

LSM0902T

LSM1002T

LSM1102T

LSM1202T

LSM1402T

LSM1602T

LSM2002T

BALL NOSE – 2 FLUTES END MILLS.

APPLICATION:

RECOMMEND – CARBON STEEL, ALLOY STEEL, PRE-HARDENED STEL, HIGHT-HARDENED STEEL TO 50 HRC.

SUITABLE – HIGHT-HARDENED STEEL TO 55 HRC, STAINLESS STEEL.

NOT RECOMMEND – HIGHT-HARDENED STEEL FROM 60 HRC TO 65 HRC, COOPER ALLOYS, ALUMINIUM ALLOYS.

SBSM0102T

SBSM0152T

SBSM0202T

SBSM0252T

BSM0102T

BSM0152T

BSM0202T

BSM0252T

BSM0302T

BSM0352T

BSM0402T

BSM0452T

BSM0502T

BSM0552T

BSM0602T

BSM0702T

BSM0802T

BSM0902T

BSM1002T

BSM1102T

BSM1202T

BSM1402T

BSM1602T

BSM1802T

BSM2002T

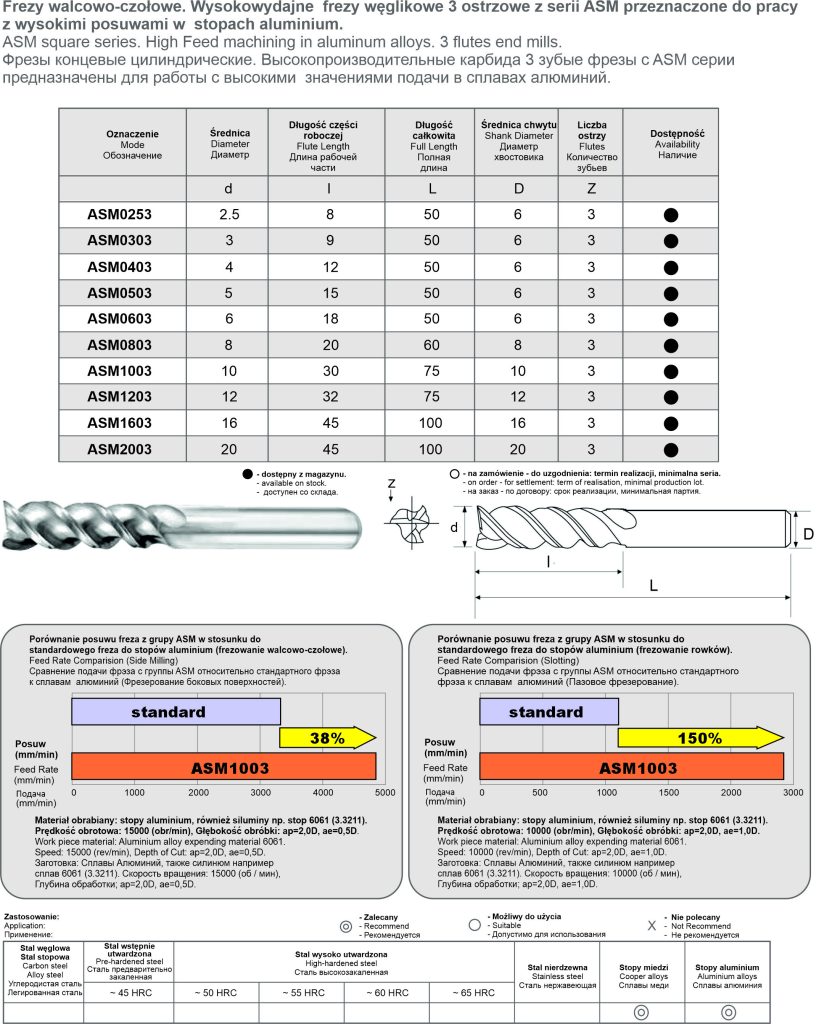

SQUARE SERIES – HIGH FEED – ALUMINIUM – 3 FLUTES END MILLS.

ASM SERIES. HIGH FEED MACHINING IN ALUMINIUM ALLOYS. 3 FLUTES CARBIDE END MILLS

APPLICATION:

– ALUMINIUM AND COPPER ALLOYS.

ASM0253

ASM0303

ASM0403

ASM0503

ASM0603

ASM0803

ASM1003

ASM1203

ASM1603

ASM2003

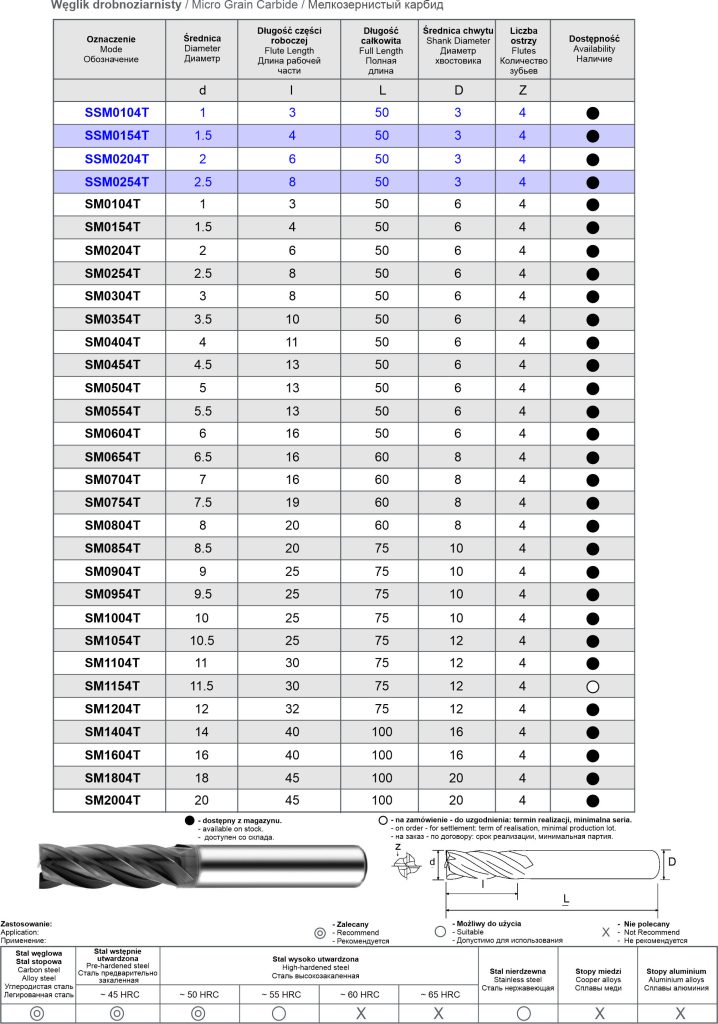

SQUARE SERIES – 4 FLUTES END MILLS.

APPLICATION:

RECOMMEND – CARBON STEEL, ALLOY STEEL, PRE-HARDENED STEL, HIGHT-HARDENED STEEL TO 50 HRC.

SUITABLE – HIGHT-HARDENED STEEL TO 55 HRC, STAINLESS STEEL.

NOT RECOMMEND – HIGHT-HARDENED STEEL FROM 60 HRC TO 65 HRC, COOPER ALLOYS, ALUMINIUM ALLOYS.

SSM0104T

SSM0154T

SSM0204T

SSM0254T

SM0104T

SM0154T

SM0204T

SM0254T

SM0304T

SM0354T

SM0404T

SM0454T

SM0504T

SM0554T

SM0604T

SM0654T

SM0704T

SM0754T

SM0804T

SM0854T

SM0904T

SM0954T

SM1004T

SM1054T

SM1104T

SM1154T

SM1204T

SM1404T

SM1604T

SM1804T

SM2004T

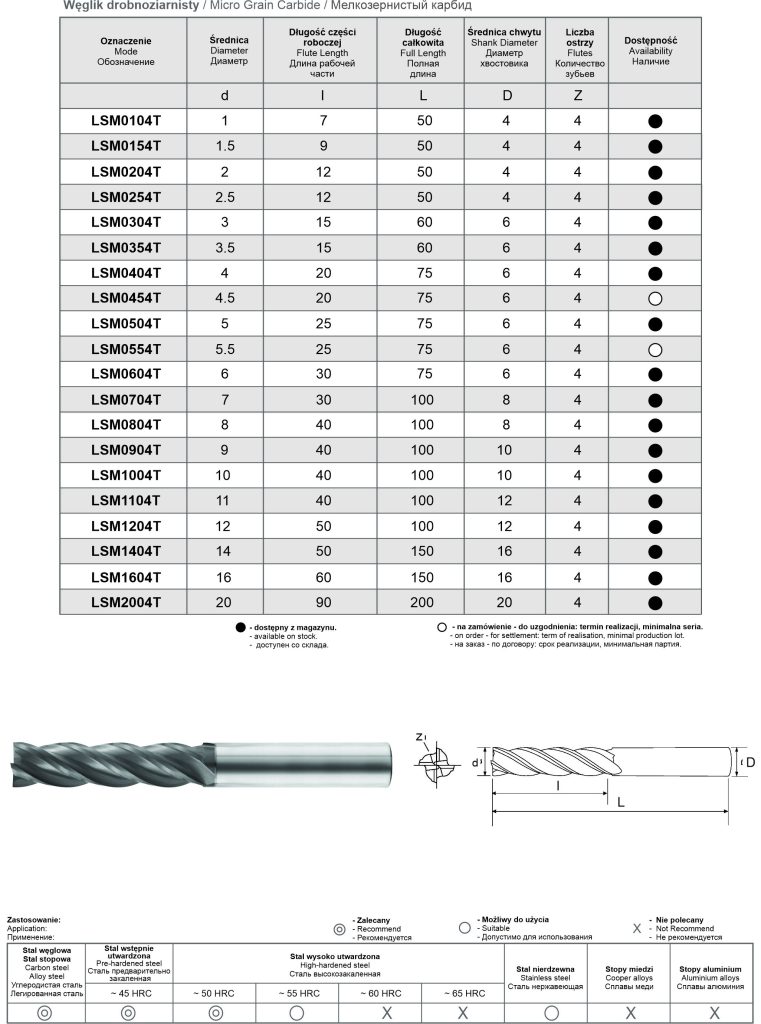

SQUARE SERIES – LONG FLUTE – 4 FLUTES END MILLS.

APPLICATION:

RECOMMEND – CARBON STEEL, ALLOY STEEL, PRE-HARDENED STEL, HIGHT-HARDENED STEEL TO 50 HRC.

SUITABLE – HIGHT-HARDENED STEEL TO 55 HRC, STAINLESS STEEL.

NOT RECOMMEND – HIGHT-HARDENED STEEL FROM 60 HRC TO 65 HRC, COOPER ALLOYS, ALUMINIUM ALLOYS.

LSM0104T

LSM0154T

LSM0204T

LSM0254T

LSM0304T

LSM0354T

LSM0404T

LSM0454T

LSM0504T

LSM0554T

LSM0604T

LSM0704T

LSM0804T

LSM0904T

LSM1004T

LSM1104T

LSM1204T

LSM1404T

LSM1604T

LSM2004T

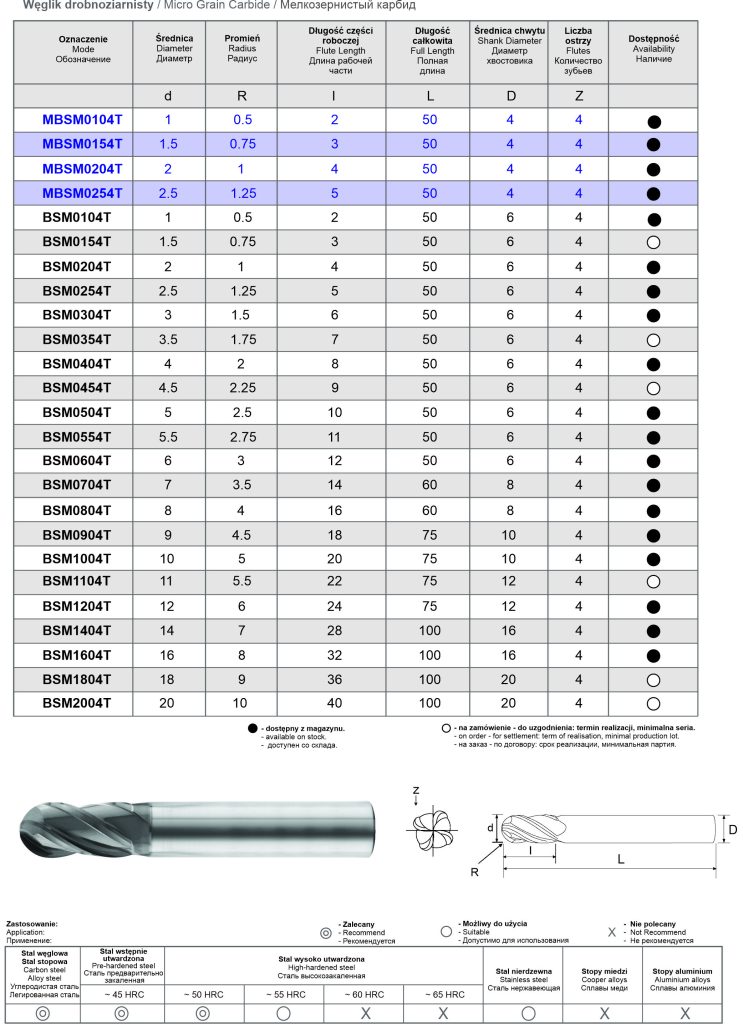

BALL NOSE – 4 FLUTES END MILLS.

APPLICATION:

RECOMMEND – CARBON STEEL, ALLOY STEEL, PRE-HARDENED STEL, HIGHT-HARDENED STEEL TO 50 HRC.

SUITABLE – HIGHT-HARDENED STEEL TO 55 HRC, STAINLESS STEEL.

NOT RECOMMEND – HIGHT-HARDENED STEEL FROM 60 HRC TO 65 HRC, COOPER ALLOYS, ALUMINIUM ALLOYS.

MBSM0104T

MBSM0154T

MBSM0204T

MBSM0254T

BSM0104T

BSM0154T

BSM0204T

BSM0254T

BSM0304T

BSM0354T

BSM0454T

BSM0504T

BSM0554T

BSM0604T

BSM0704T

BSM0804T

BSM0904T

BSM1004T

BSM1104T

BSM1204T

BSM1404T

BSM1604T

BSM1804T

BSM2004T

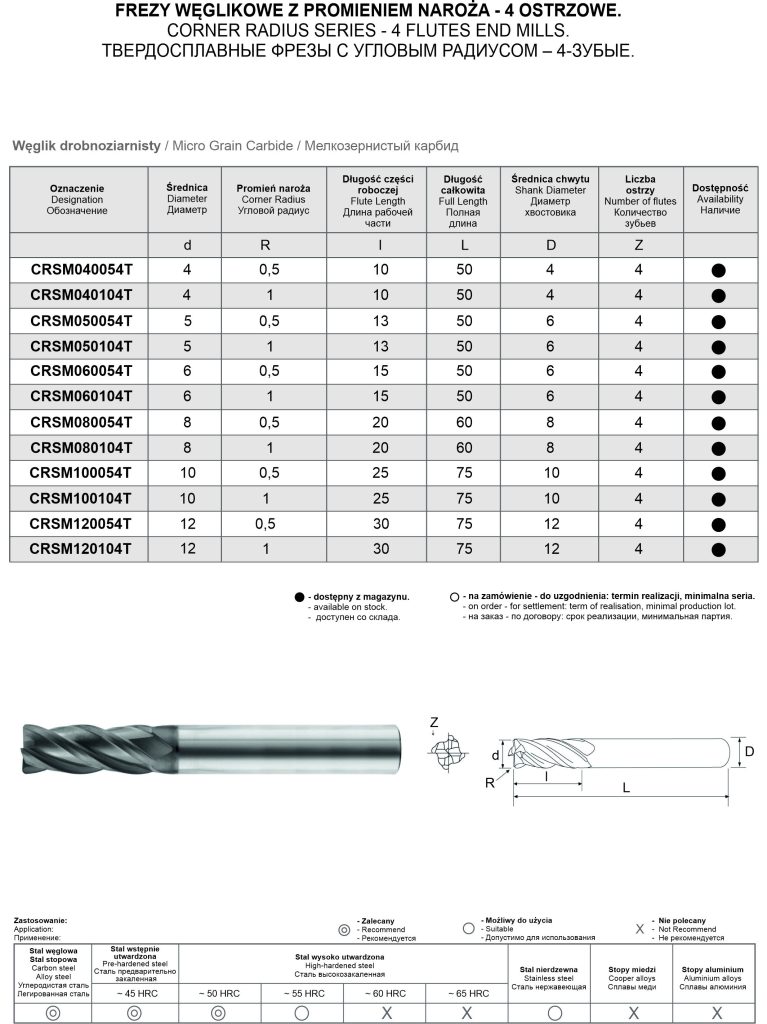

CORNER RADIUS SERIES – 4 FLUTES END MILLS.

APPLICATION:

RECOMMEND – CARBON STEEL, ALLOY STEEL, PRE-HARDENED STEL, HIGHT-HARDENED STEEL TO 50 HRC.

SUITABLE – HIGHT-HARDENED STEEL TO 55 HRC, STAINLESS STEEL.

NOT RECOMMEND – HIGHT-HARDENED STEEL FROM 60 HRC TO 65 HRC, COOPER ALLOYS, ALUMINIUM ALLOYS.

CRSM040054T

CRSM040104T

CRSM050054T

CRSM050104T

CRSM060054T

CRSM060104T

CRSM080054T

CRSM080104T

CRSM100054T

CRSM100104T

CRSM120054T

CRSM120104T

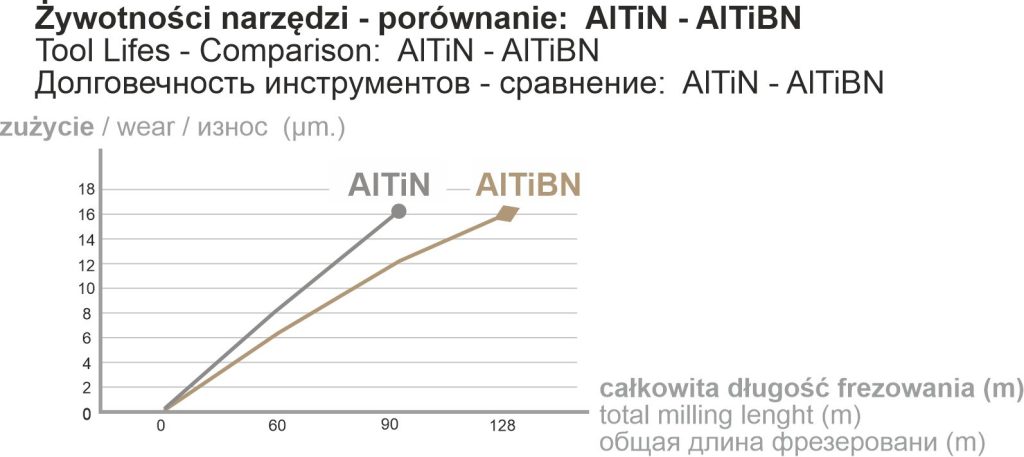

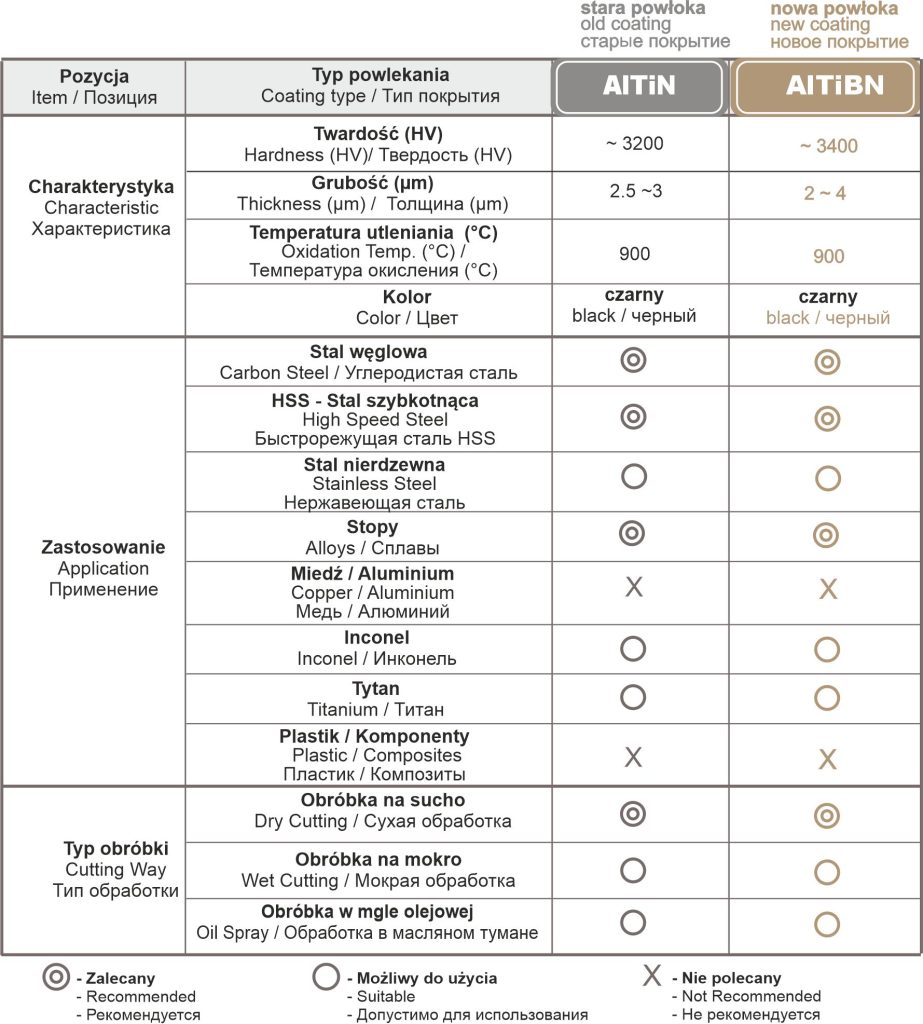

END MILLS WITH THE NEW ALTIBN COATING OF 2 TO 4 µM COATINGS WITH IMPROVED TECHNICAL PARAMETERS. HV HARDNESS UP TO 3400.

APPLICATION MAINLY FOR CARBON STEEL, HSS – HIGH-SPEED STEEL, IRON ALLOYS AND ALSO POSSIBLE FOR USE ON STAINLESS STEEL, INCONEL, AND TITANIUM. DRY MACHINING.

see the PAFANA on-line catalog: http://pafana.elkat.eu/#0

see the assortment of the PAFANA catalog edition 07/2020: https://pafana.pl/en/products/carbide-end-mills-smart-line-pafana-square-series-2-flutes-end-mills-square-series-long-flute-2-flutes-end-mills-ball-nose-2-flutes-end-mills-square-series-high-feed-aluminium-3-flutes-square-series/

see PAFANA news: https://pafana.pl/en/products/new/